Method for correcting span during rock blasting damage cross-hole sound wave test

A technology for cross-hole sonic and rock blasting, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measurement devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

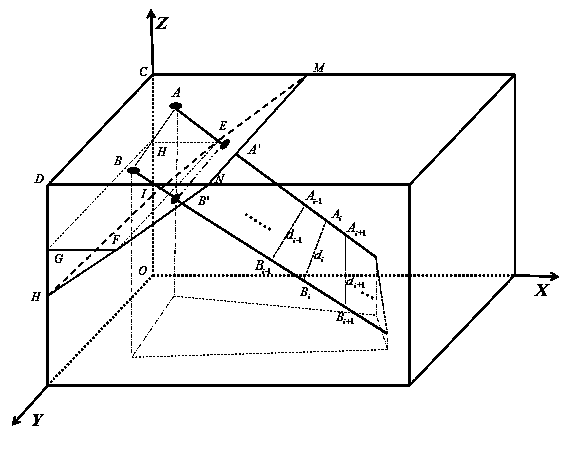

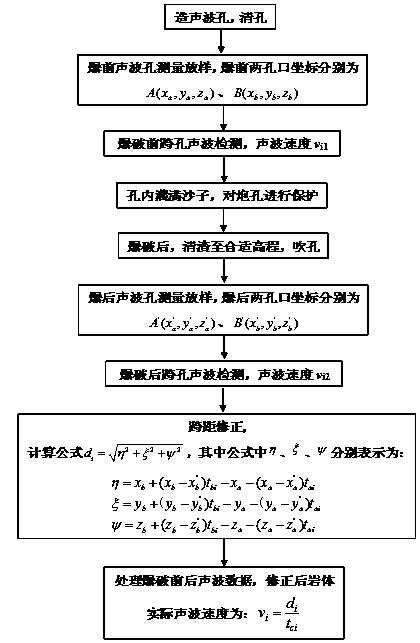

[0049] The basic process of span correction in the cross-hole acoustic wave test is attached image 3 As shown, the specific implementation steps are:

[0050] (1) Drill two parallel oblique sonic test holes A and B on the surface of the explosion area, and pass through the explosion area to reach the reserved pre-split surface. The depth of the acoustic test hole through the pre-split surface is greater than 7 meters, and the hole is cleaned.

[0051] (2) Stake out and measure the sonic test holes before blasting, and determine the orifice coordinates A(x a ,y a ,z a ), B(x b ,y b ,z b ).

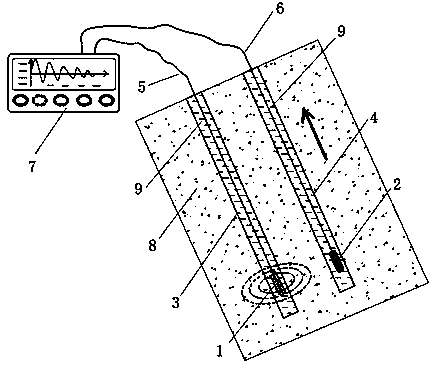

[0052] (3) Conduct the first cross-hole acoustic wave test 1 to 2 days before blasting, and connect the transmitting transducer and receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com