Aerial photography damping damper

A shock-absorbing damping and damper technology, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of potential safety hazards, poor load-bearing capacity and mechanical strength of shock-absorbing balls, and achieve the elimination of safety problems. Hidden danger, good mechanical strength and load-bearing capacity, and the effect of suppressing high-frequency vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

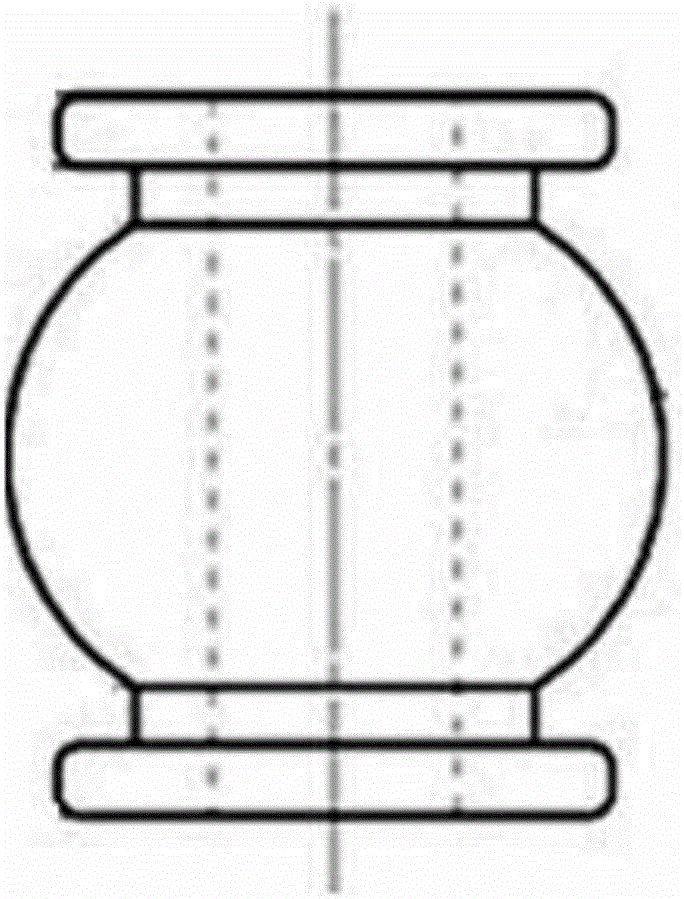

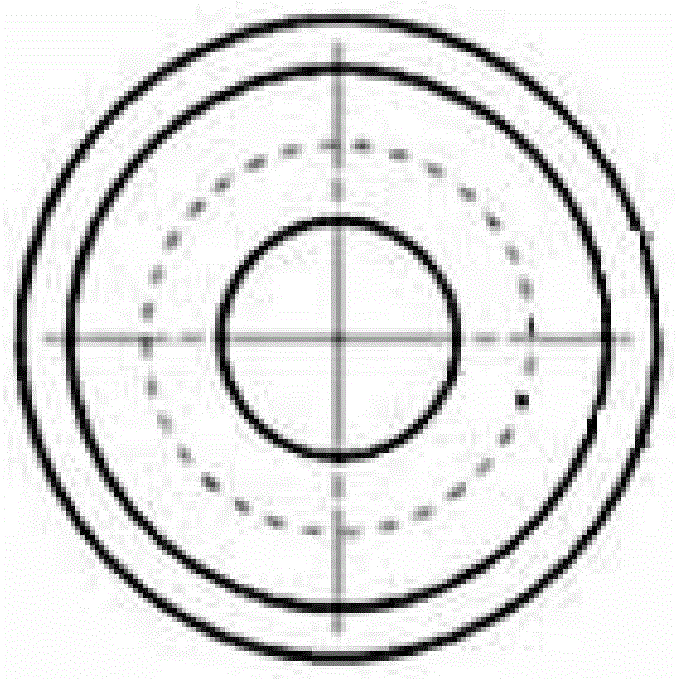

[0023] Specific implementation mode 1: Combination Figure 3 to Figure 6 To illustrate this embodiment, an aerial damping damper described in this embodiment includes a viscoelastic material filling layer 1, an upper damper shell 2, a lower damper shell 3, a fixing member, and a buffer spring 6;

[0024] The upper shell plate 2 of the damper and the lower shell plate 3 of the damper are fixedly connected by a fixing member. A gap is formed between the outer side wall of the upper damper shell plate 2 and the inner side wall of the lower damper shell plate 3, and the gap is filled with viscoelasticity Material filling layer 1;

[0025] The fixing piece passes through the center of the upper damper shell 2 and the lower damper shell 3, the buffer spring 6 is sleeved on the fixing piece, and the two ends of the buffer spring 6 are respectively fixed to the upper damper shell 2 and the lower damper shell In the groove of 3, the free length of the buffer spring 6 is greater than the d...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment is a further limitation of the aerial damping damper described in Embodiment 1. The outer side wall of the upper damper shell 2 and the inner side wall of the lower damper shell 3 are Slope parallel to each other.

[0028] In this embodiment, the viscoelastic material filling layer 1 is made of viscoelastic material, and the tangential vibration is mainly composed of the viscoelastic material 1 through the shear deformation of the upper shell plate 2 of the damper and the lower shell plate 3 of the damper. The purpose of dissipating vibration energy.

specific Embodiment approach 3

[0029] Specific embodiment three: this embodiment is a further limitation of the aerial damping damper described in specific embodiment two, and the viscoelastic material filling layer 1 reaches the maximum.

[0030] In this embodiment, the larger the volume of the viscoelastic material filling layer 1 is, the more vibration energy is dissipated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com