Super-high power ultrasonic crude oil cooling transportation and viscosity reduction device

An ultra-high-power, ultrasonic technology, applied in mechanical equipment, pipeline systems, gas/liquid distribution and storage, etc., can solve problems such as cold sticking of oil pipelines, achieve increased radiation resistance, good stability, optimized power and original Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

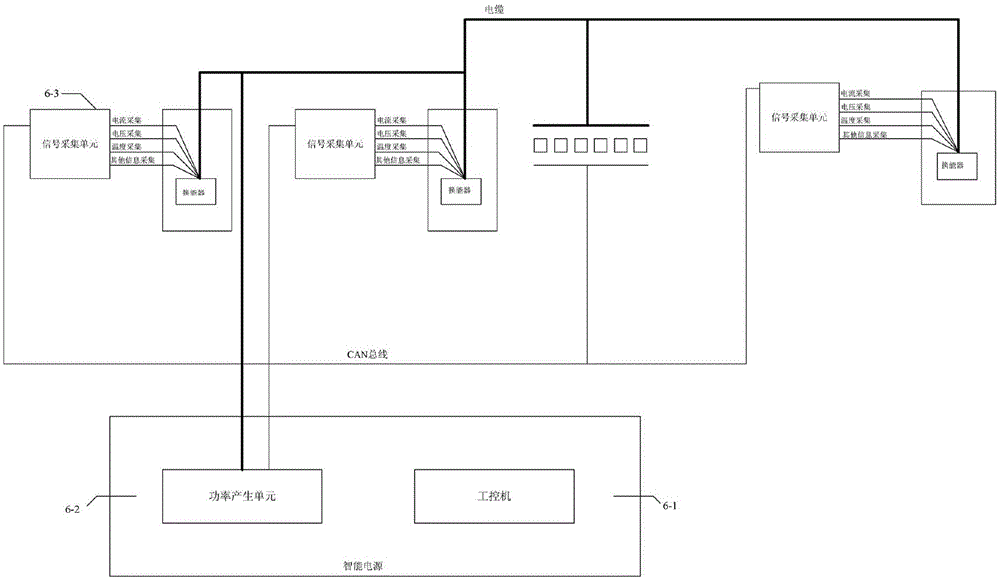

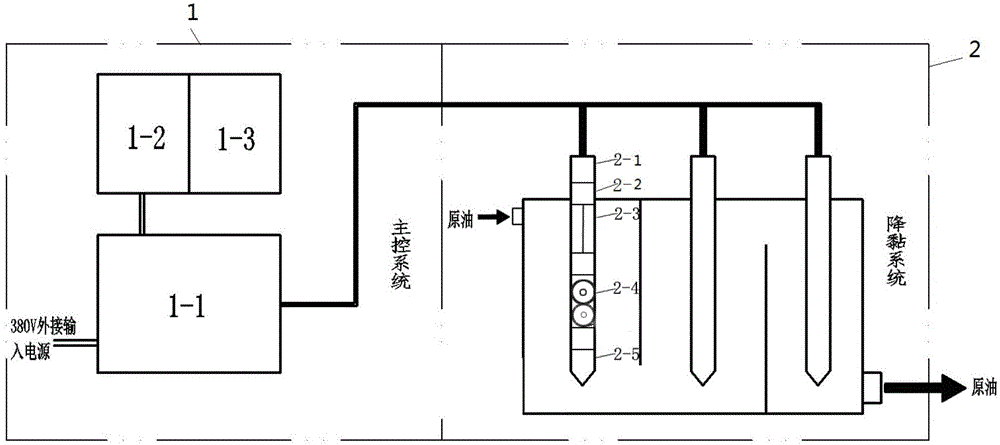

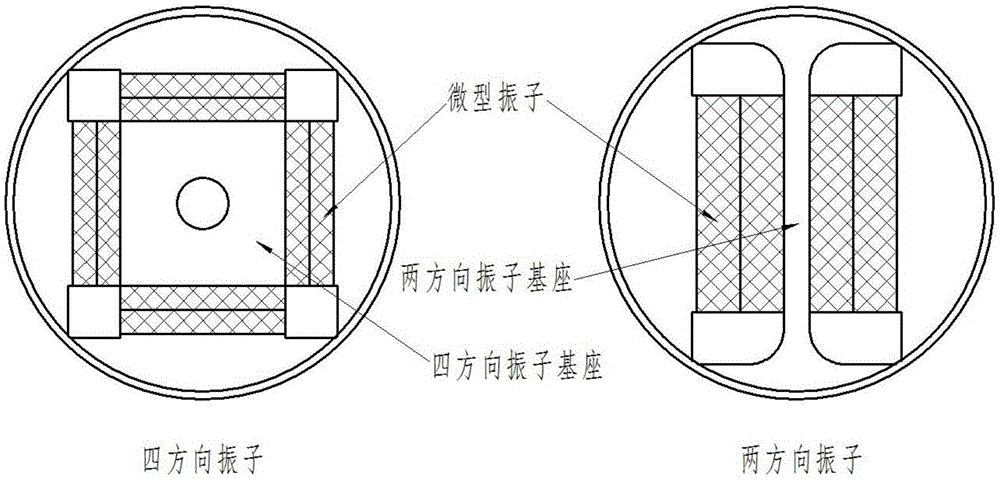

[0040] The present invention adopts the principle of ultrasonic energy conversion, and utilizes the high-density sound intensity generated by an ultrasonic transducer with a power of several thousand watts to break through the surface tension in the fluid to generate acoustic cavitation of the liquid, and the small bubbles generated continuously accumulate energy and expand continuously. When the bubbles burst, energy is released instantaneously in a small area, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com