Fault indicator comprehensive testing method and testing system

A fault indicator and comprehensive testing technology, applied in the direction of instruments, measuring devices, measuring electrical variables, etc., can solve the problems of lack of detection platform in testing institutions, uneven product quality, low pass rate of fault indicators, etc., to improve equipment The qualified rate of network access, the improvement of professional management level, and the effect of reducing the low rate of correct action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

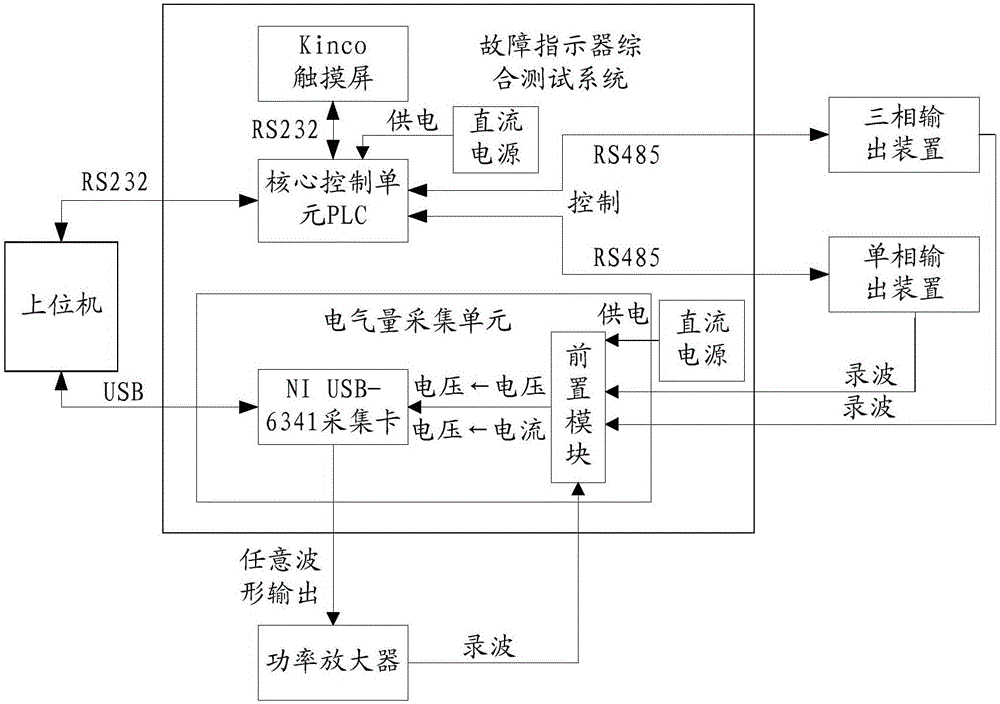

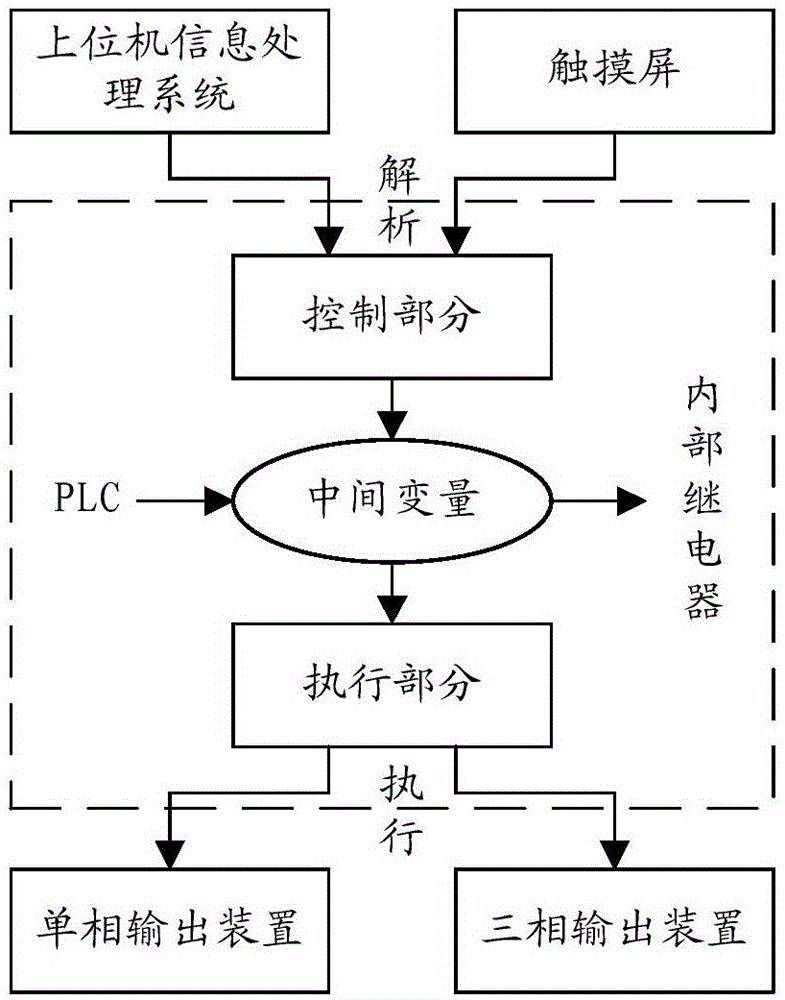

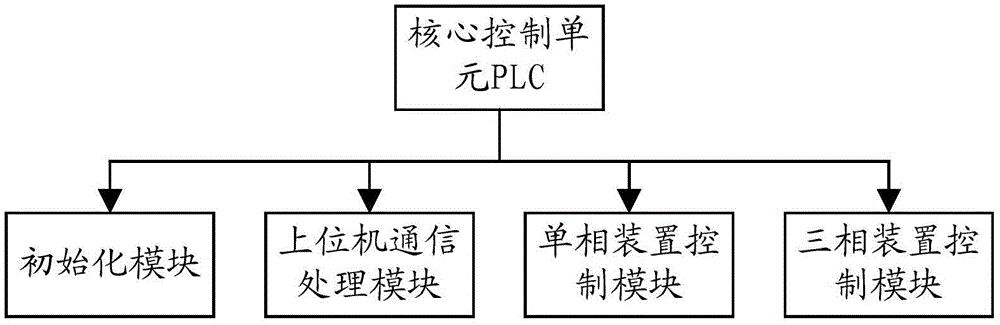

[0035] see figure 1As shown, a comprehensive testing method for a fault indicator of the present invention, the testing method needs to provide: a host computer, an electrical quantity acquisition unit, a core control unit PLC, a touch screen, a power amplifier, a three-phase output device and a single-phase output device; The core control unit PLC communicates with the information processing system of the host computer through the RS232 interface, the touch screen sends control instructions to the core control unit PLC through the RS232 interface, the core control unit PLC completes the analysis and execution of the control instructions, and the core control unit PLC passes The upper computer simulates various fault types of the distribution network, and the core control unit PLC controls the three-phase output device and single-phase output device to output the changes of voltage and current corresponding to various fault types through the RS485 interface, and collects the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com