Pre-stressed steel strand buttress system applicable for super-large type LNG (Liquefied Natural Gas) full-capacity storage tank

A technology of prestressed steel strand and buttress columns, which is applied in the field of prestressed steel strand buttress column systems, to reduce construction costs and achieve uniform and reasonable stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

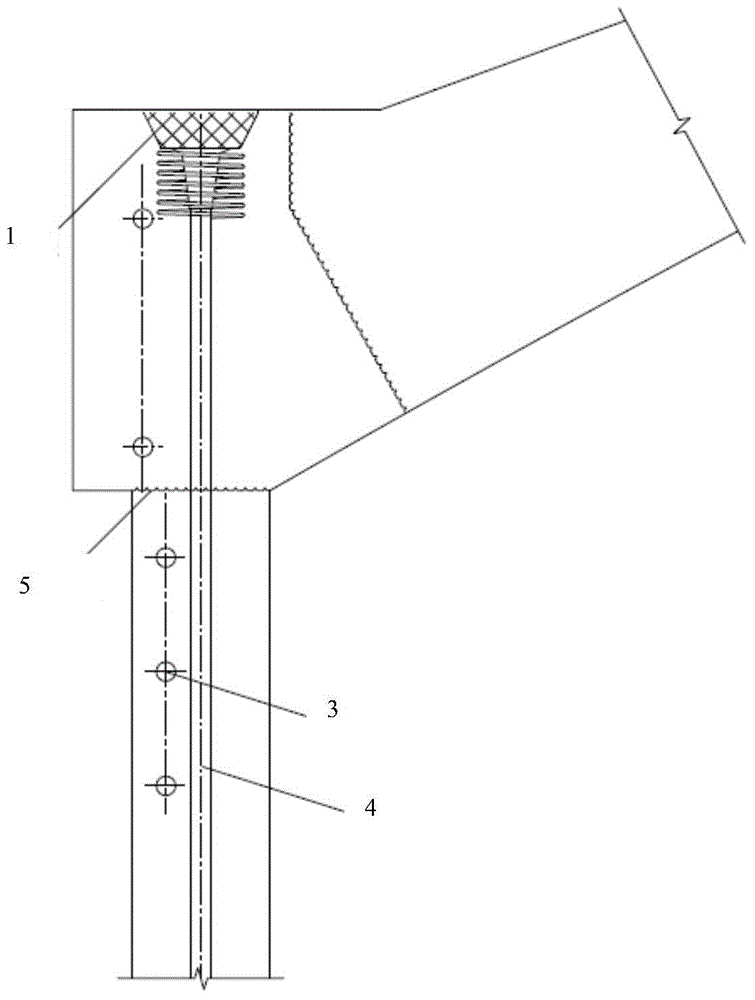

[0035] The present invention is suitable for the prestressed steel strand buttress column system of the super large LNG full-capacity storage tank, including 6 buttress columns 7 arranged outside the tank wall of the super large LNG storage tank and laying in the tank wall of the super large LNG storage tank A plurality of hoop prestressed steel strand bundles 3 and a plurality of vertical prestressed steel strand bundles 4, such as Figure 7 shown.

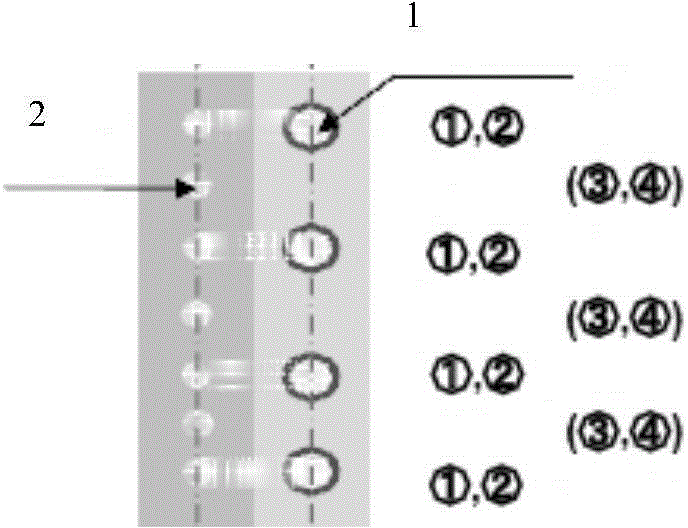

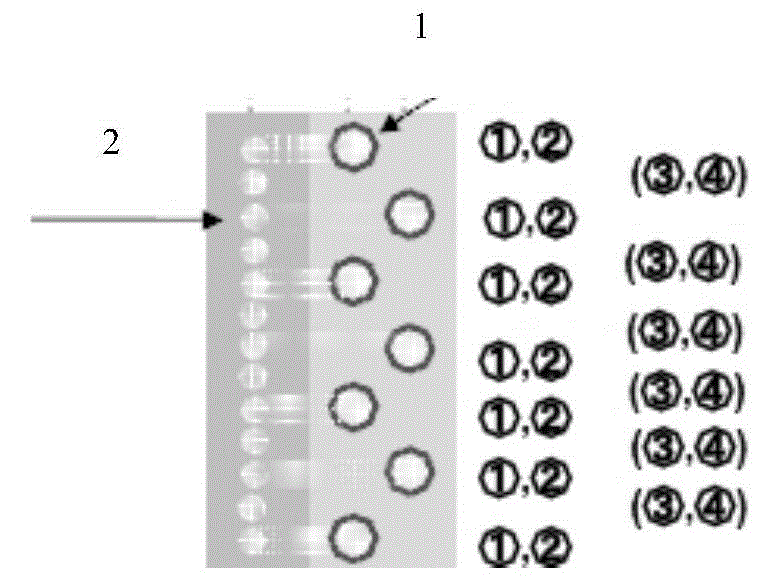

[0036] Such as image 3 As shown, the two ends of the hoop prestressed steel strand bundle 3 are fixed on the anchorages 1 at the two ends of the buttress column 7 along the circumferential direction of the super-large LNG storage tank, and the hoop prestressed steel strand bundle 3 is formed along the height of the concrete outer wall. Ring layout, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com