Epidural press-on prism and assembling method thereof

An assembly method and technology of triangular prisms, which are applied in prisms, optics, instruments, etc., can solve the problems of difficult assembly, poor ability to resist external contamination, and complicated assembly process of triangular prisms by hard film pressing, so as to achieve low assembly difficulty and good The effect of anti-external damage ability and good anti-external fouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

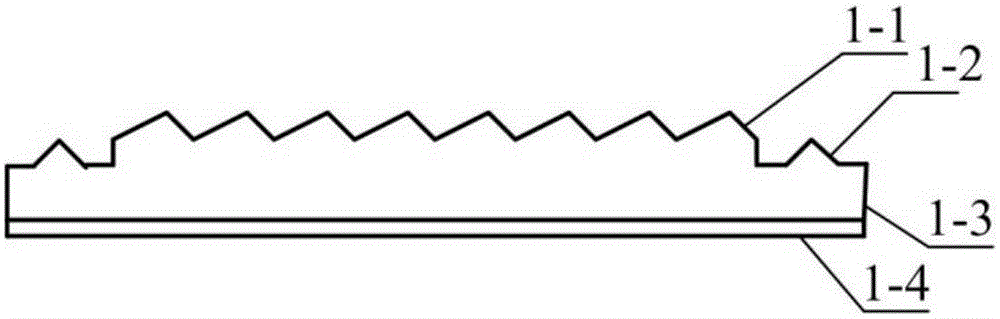

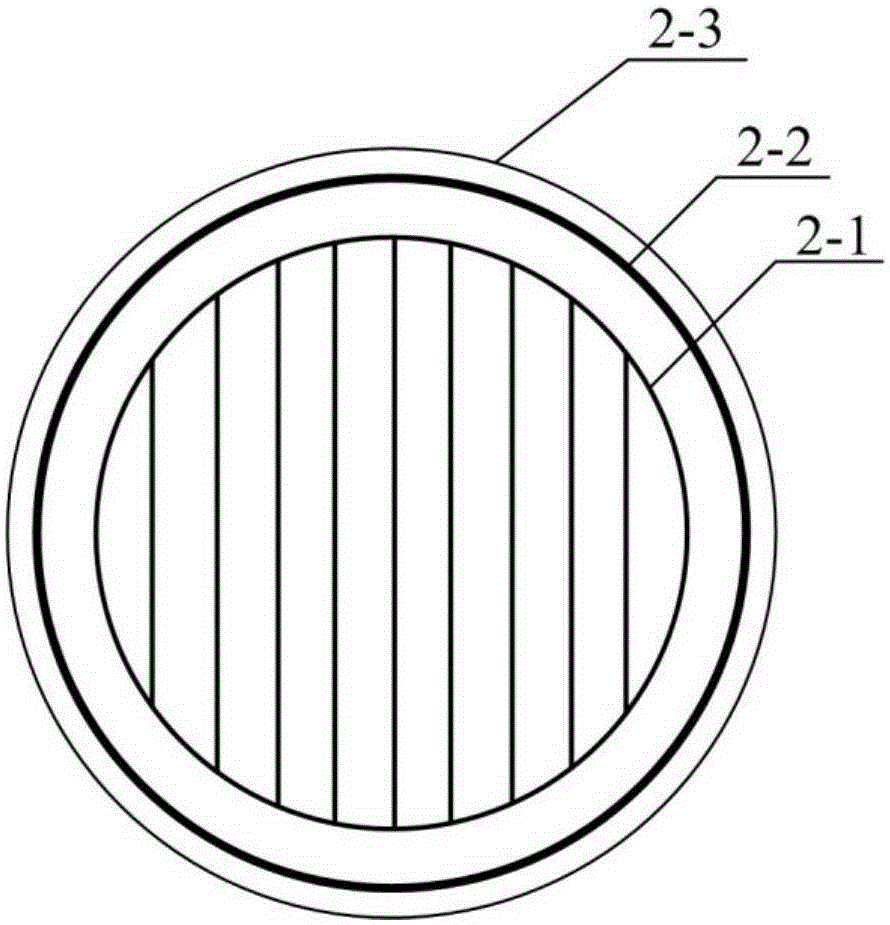

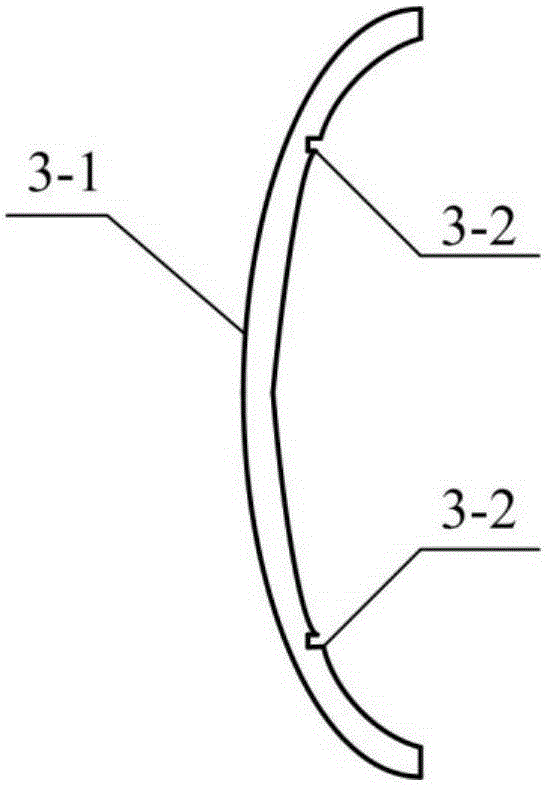

[0028] refer to Figure 1 to Figure 5 , a kind of dura mater pressing prism, comprises optical surface microstructure, assembly convex groove, material base and dura protective layer, and described material base adopts the base of PMMA polymer material, and the light transmittance of described PMMA polymer material reaches 99%, the upper surface of the material substrate is an optical surface microstructure, and the optical surface microstructure adopts a Fresnel optical microstructure, and the assembly convex groove surrounds the periphery of the optical surface microstructure, and the material substrate The bottom surface is a hard film protective layer.

[0029] Further, the fitting convex groove is a circular V-shaped convex groove. Of course, other shapes are also possible.

[0030] Still further, the hard coat protective layer is a protective layer obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com