A kind of preparation method of thickener for temperature-resistant double network structure fracturing fluid

A network structure and thickening agent technology, applied in the field of oilfield chemicals and fine chemistry, can solve the problems of difficulty in meeting high temperature oilfield fracturing, secondary damage to the formation, loss of application value, etc., and achieve good resistance to external damage, resistance to The effect of improving temperature capacity and strong hydrogen bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

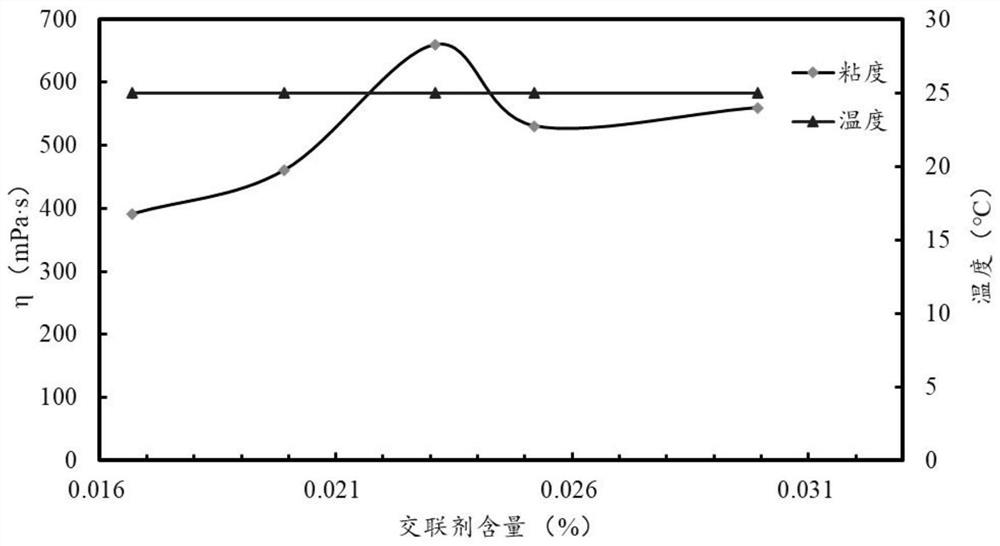

[0025] A preparation method of a temperature-resistant double network structure fracturing fluid thickener:

[0026] Prepare 5 kinds of thickener samples according to the proportioning ratio of each raw material component in Table 1:

[0027] Table 1, the content ratio of each raw material component of 5 kinds of thickeners

[0028]

[0029] 3 parts of deionized water were added to the reaction system in 3 parts.

[0030] Add the first layer of network functional polymer polyvinyl alcohol formate into 5 reaction kettles respectively, seal and stir in 1 part of deionized water at 93°C for 2 hours, stirring at 450 rpm, and dissolve to obtain a temperature-resistant double network structure fracturing fluid thick Agent first layer network solution.

[0031] After the reactor is cooled to room temperature, add the second part of deionized water to the reactor, stir on a magnetic stirrer for 7 minutes, add the second layer of network non-ionic monomer N-methylolacrylamide to t...

Embodiment 2

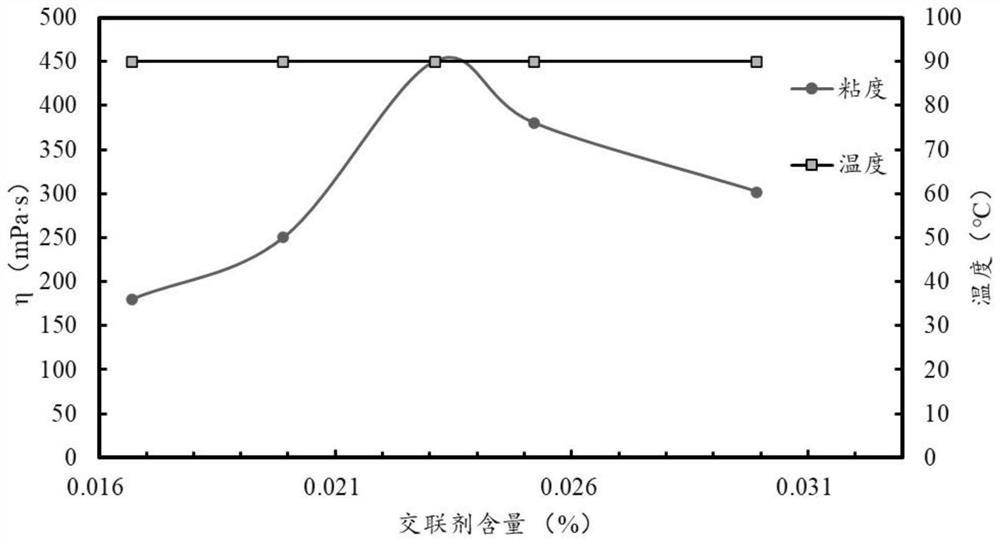

[0037] A preparation method of a temperature-resistant double network structure fracturing fluid thickener:

[0038] Prepare 5 kinds of thickener samples according to the proportioning ratio of each raw material component in Table 2:

[0039] Table 2, the content ratio of each raw material component of 5 kinds of thickeners

[0040]

[0041]3 parts of deionized water were added to the reaction system in 3 parts. Add the first layer of network functional polymer polyvinyl alcohol formate into 5 reactors, seal and stir in 1 part of deionized water at 92°C for 2 hours, and dissolve to obtain the first layer of temperature-resistant double network structure fracturing fluid thickener Network solution; wherein, the stirring speed is 460rpm, and the dosage of the first layer network functional polymer is 0.170%, 0.255%, 0.340%, 0.425%, 0.510% of the total mass of reactants.

[0042] After the reaction kettle is cooled to room temperature, add the second part of deionized water ...

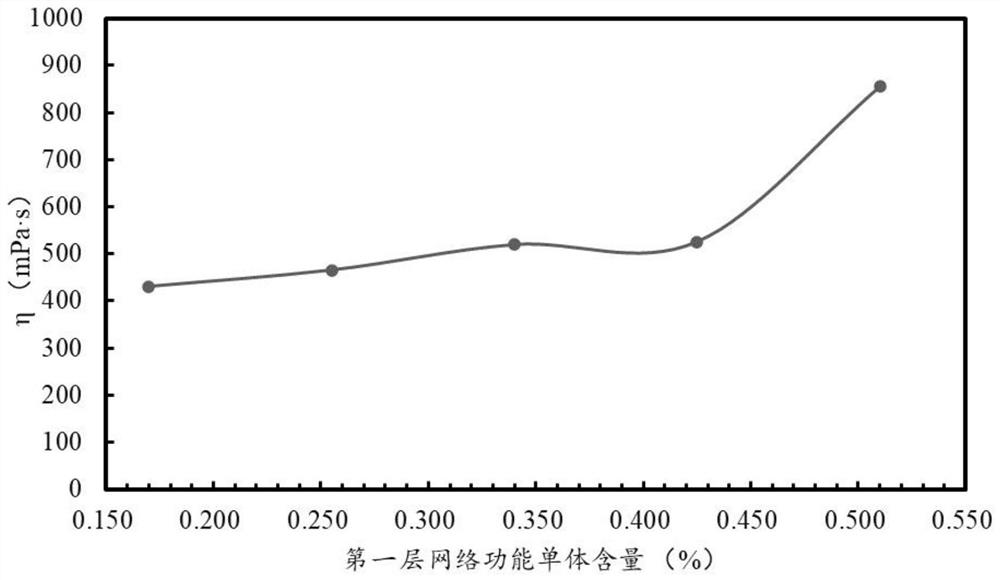

Embodiment 3

[0047] This example provides a method for preparing a temperature-resistant double network structure fracturing fluid thickener:

[0048] 3 parts of deionized water were added to the reaction system in 3 parts. Add the first layer of network functional polymer polyvinyl alcohol formate into the reaction kettle, seal and stir in 1 part of deionized water at 92°C for 2 hours, and dissolve to obtain the first layer network solution of temperature-resistant double network structure fracturing fluid thickener ; Wherein, the stirring speed is 400-500rpm, and the dosage of the first-layer network functional polymer is 0.340% of the total mass of reactants.

[0049] After the reactor is cooled to room temperature, add the second portion of deionized water to the reactor, stir on a magnetic stirrer for 6 minutes, add the second layer of network non-ionic monomer N-methylolacrylamide into the reactor, Stir on a magnetic stirrer for 9 minutes to obtain the first layer network solution a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com