Rib steel concrete member

A technology of concrete and components, applied in the direction of building components, building structures, building materials, etc., can solve problems such as easy cracks and complex structures of prefabricated components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

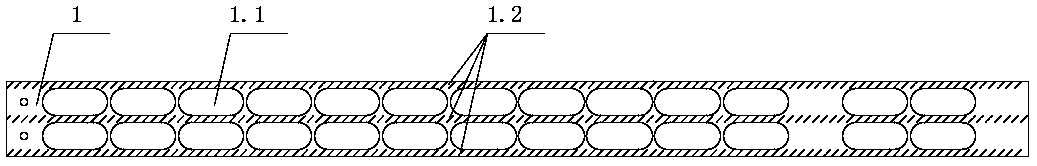

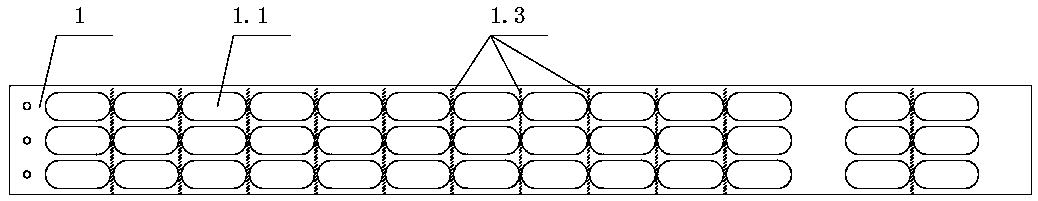

[0023] Such as Figures 1 to 4 As shown, a ribbed concrete member includes a steel plate 1 rolled as a whole. The steel plate 1 encloses a hollow part that runs through both ends and a member with a closed cross section, such as a column or a plate. The steel plate 1 is provided with a hollow Concrete 1.4 is provided in the hole 1.1 and the rib, the hollow part and the hollow hole 1.1. The rib includes at least two rows of longitudinal ribs 1.3 arranged vertically and at least one row of transverse ribs 1.2 arranged transversely. Between them, the longitudinal rib 1.3 is located between two vertically adjacent holes 1.1 or between the hole 1.1 and the side of the steel plate 1, and the positions of the transverse rib 1.2 and the longitudinal rib 1.3 are aligned. Specifically, the continuous steel strip along the long direction is the longitudinal rib 1.3, which acts as the reinforced steel bar in the reinforced concrete structure; When the rib steel is processed or the struct...

Embodiment 2

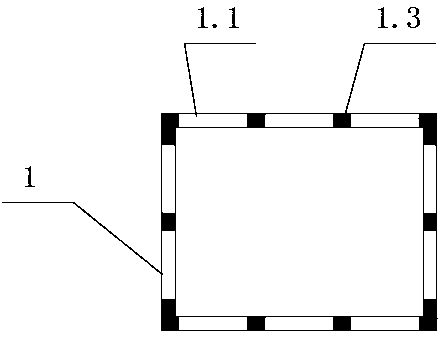

[0028] Such as image 3 and 4 As shown, a ribbed concrete member, the member includes four steel plates 1, the four steel plates 1 are tailor-welded into a column or beam with a rectangular cross-section, a hollow interior, and a hollow penetrating through both ends, and the hollow part and the hole Concrete is poured to form ribbed concrete members.

[0029] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com