Air-cooling dry type air-core reactor structure

A technology of air-core reactors and reactors, which is applied in the direction of transformer/inductor cooling, signal inductors without magnetic cores, etc., which can solve the problem of uneven wind speed in the air passage of reactors, reduce the withstand voltage level of reactors, and affect reactors. Safe operation and other issues to achieve the effect of improving heat dissipation efficiency and heat dissipation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are described in detail below:

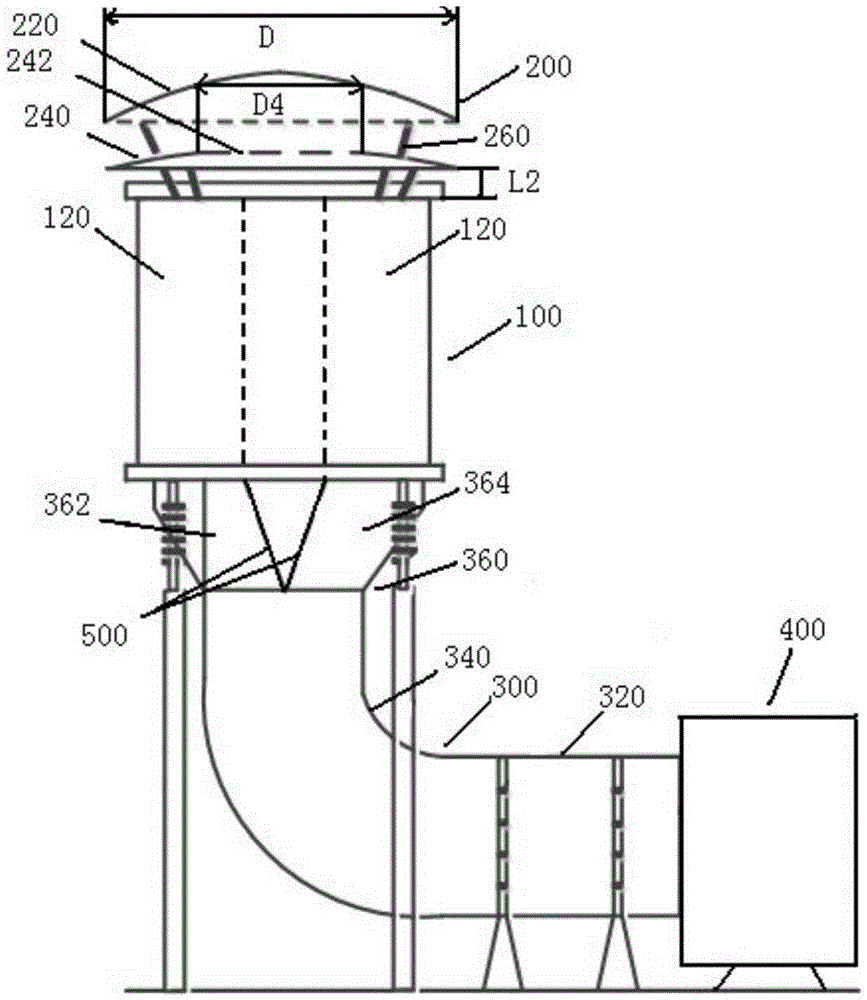

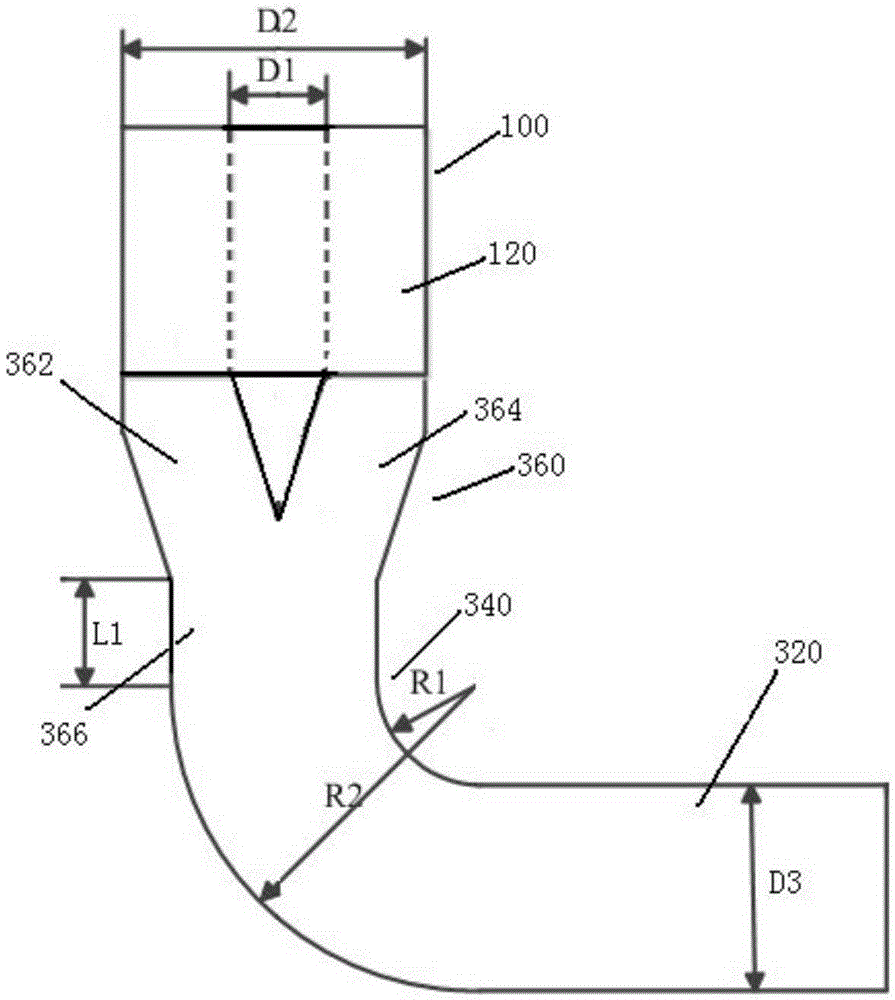

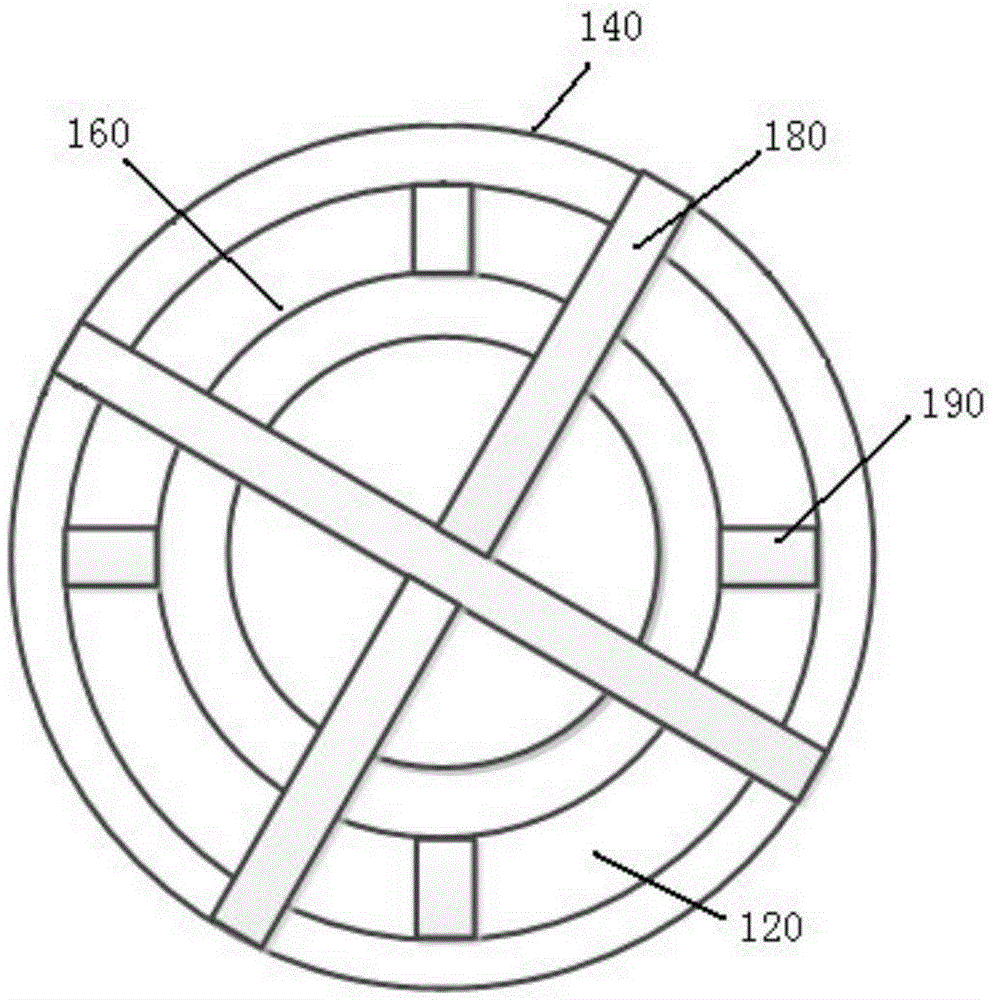

[0027] Such as figure 1 As shown, an air-cooled dry-type air-core reactor structure includes a reactor 100 provided with a heat dissipation channel 120, a ventilation duct 300 communicated with the heat dissipation duct 120, and an air supply device communicated with the ventilation duct 300 400, the ventilation duct 300 includes a horizontal section duct 320, an arc section duct 340 and a vertical section duct 360 connected in sequence, and the end of the vertical section duct 360 away from the arc section duct 340 forms a first air flow The passage 362 and the second airflow passage 364 , both of the first airflow passage 362 and the second airflow passage 364 communicate with the heat dissipation passage 120 .

[0028] The above-mentioned air-cooled dry-type air-core reactor structure includes the ventilation duct 300 and the air supply device 400 that communicate with each other, and the air supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com