High-voltage switch cabinet capable of being automatically cooled and cleaned

A high-voltage switchgear, automatic cooling technology, applied in substation/switch layout details, substation/switchgear cooling/ventilation, electrical components, etc., can solve the problems of reducing the service life of electrical components, dusty, poor heat dissipation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

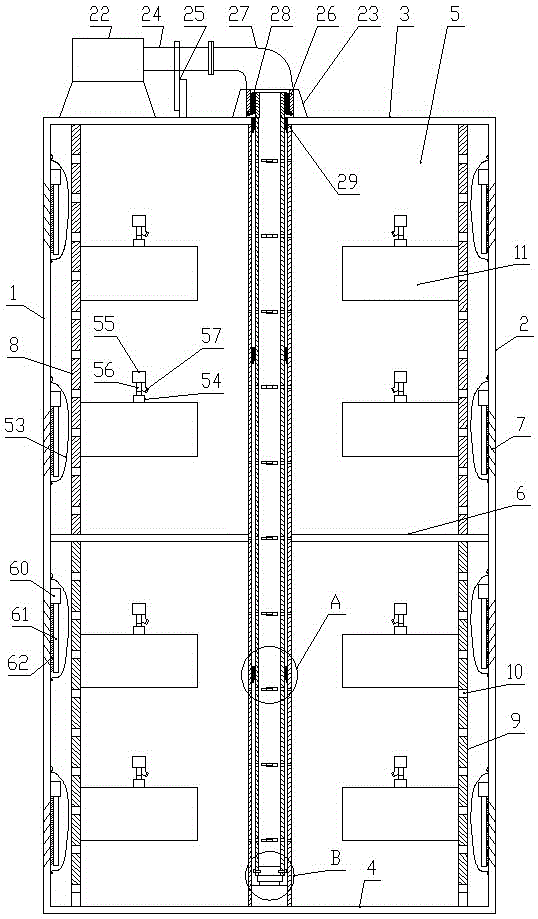

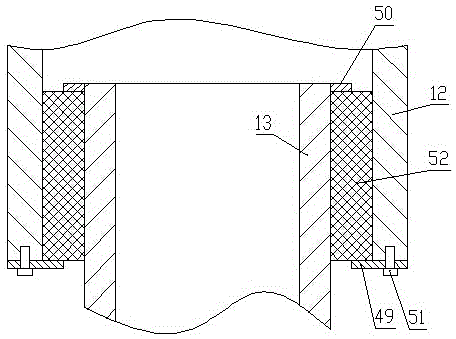

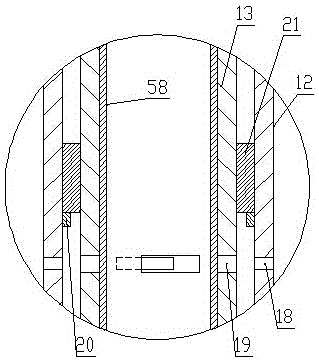

[0028] Such as Figure 1-Figure 7 As shown, the automatic cooling and cleaning high-voltage switchgear of the present invention includes a cabinet in the shape of a cuboid, and the cabinet consists of a left side panel 1, a right side panel 2, a top panel 3, a bottom panel 4, a rear side panel 5 and a cabinet door (Fig. not shown in ), a partition 6 is arranged horizontally between the left side panel 1 and the right side panel 2, shutters 7 are respectively arranged on the left side panel 1 and the right side panel 2, and the inner wall of the left side panel 1 and the right side panel 2 The inner wall is provided with a cleaning mechanism at the shutter 7, and a left vertical board 8 and a right vertical board 9 are arranged between the top board 3 and the bottom board 4, the left vertical board 8 is parallel to and adjacent to the left side board 1, and the right vertical board 9 is connected to the The right side plate 2 is parallel and adjacent, and the left vertical plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com