Automatic press-fitting machine for making shoes

A fast-fitting machine and automatic technology, applied in shoe-making machinery, footwear, applications, etc., can solve problems such as uneven fastening quality, uneven appearance, low production efficiency, etc., to save labor costs, The effect of the product is excellent and the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

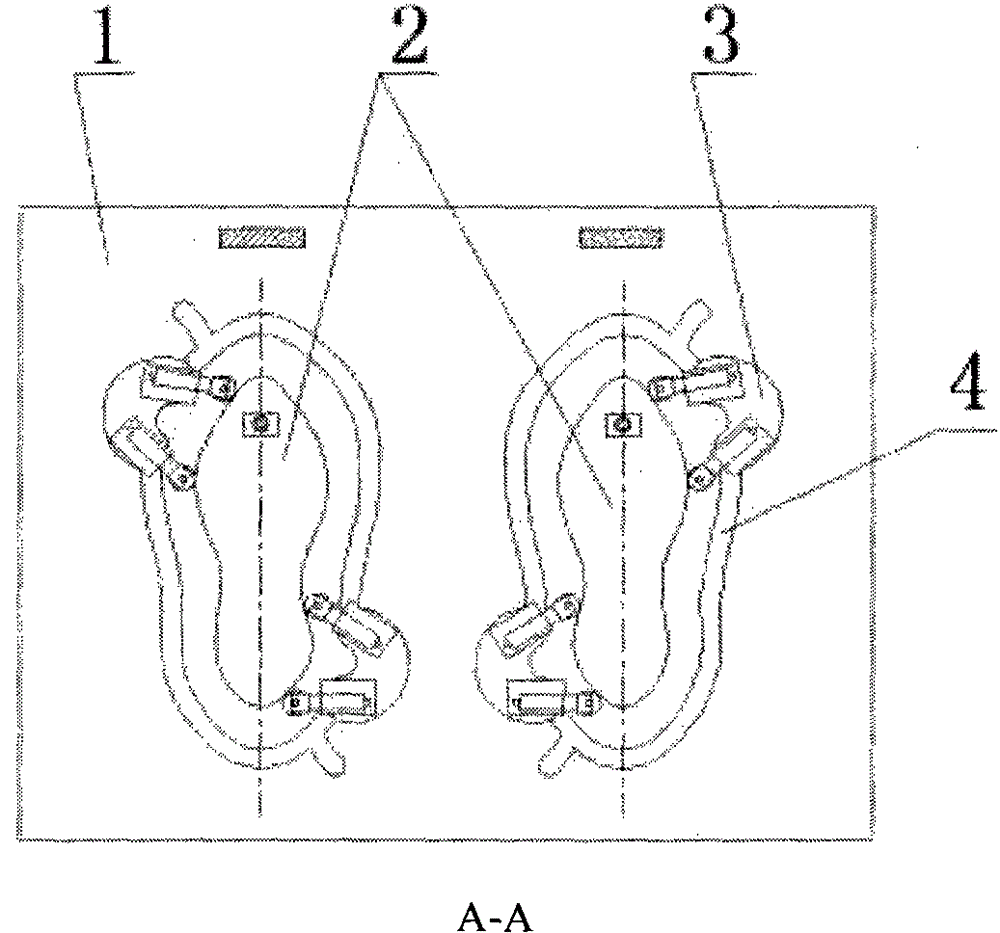

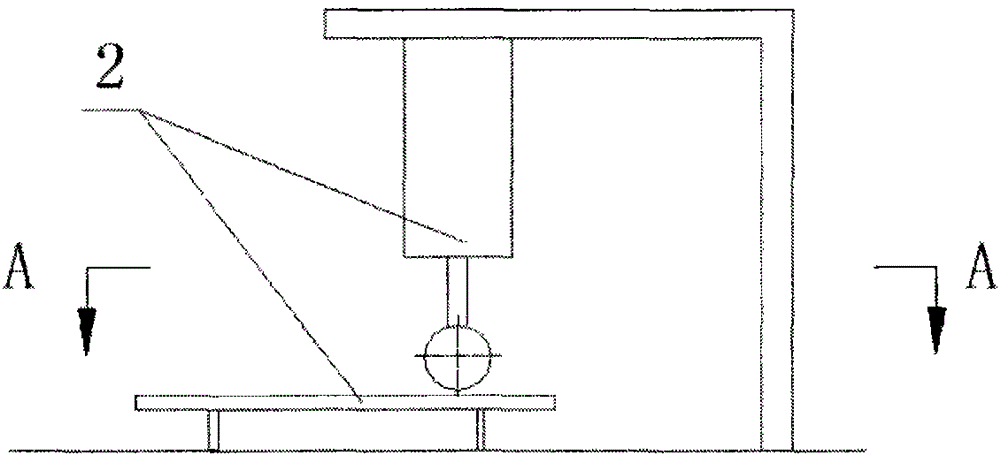

[0033] Taking a single-sided operating platform as an example, the present invention includes a power device (not shown), a shoe body supporting and fixing device 2, an operating table 1 and a linkage fastener 3, among which there are many linkage fasteners 3 To four round table type fasteners 7.

[0034] In the technical scheme of the present invention, it also has the following additional technical features:

[0035] In order to fix the tightly fitted shoe body, before the equipment is operated, the shoe body is reversely buckled and wrapped around the shoe body supporting device 2, and then the fixed hammer of the shoe body fixing device 2 is lowered to tightly press the shoe body.

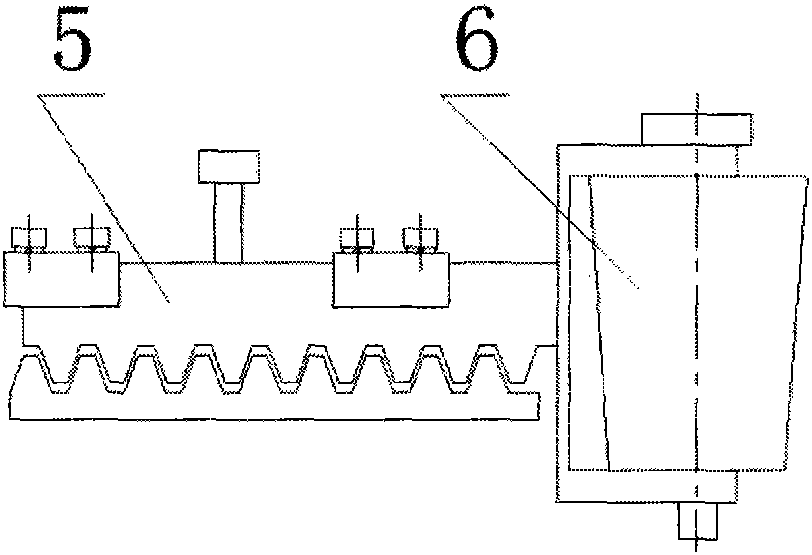

[0036] In order to ensure that during the fastening process, the shoe body will not be deformed due to excessive fastening pressure or insufficient fastening due to too small fastening pressure, you should first adjust the length of the telescopic rod 5 on the linkage fastener 3, that is, adjust the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com