Organic waste gas treatment device and method

A technology of organic waste gas and treatment device, applied in separation methods, chemical instruments and methods, and air quality improvement, etc., can solve the problems of air discharge, high investment and operating costs, troublesome activated carbon replacement and regeneration, etc. The effect of low system energy consumption and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Combine below Attached picture The present invention is further described.

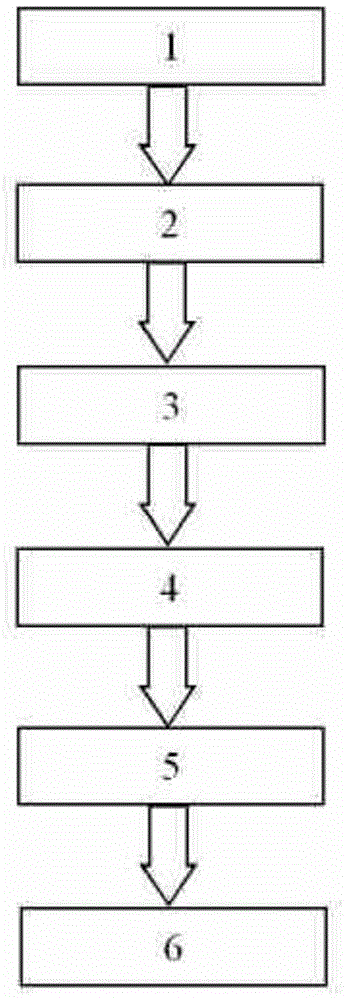

[0024] Such as attached figure 1 As shown, the present invention proposes an organic waste gas treatment device, which is characterized in that it is provided with a dedusting chamber 1, a cooling treatment mechanism 2, a photocatalytic oxidation mechanism 3, a biochemical spray filter mechanism 4, a demister mechanism 5 and an adsorption mechanism connected in sequence. 6, wherein the biochemical spray filter mechanism 4 includes sequentially connected chemical scrubbers for spraying organic waste gases with chemical agents, biological scrubbers for spraying organic waste gases with biological agents, and biological filters for filtering organic waste gases device; the photocatalytic oxidation mechanism 3 includes a corrugated guide plate, a photocatalytic oxidizer and a filter for controlling the gas flow state, and the corrugated guide plate, photocatalytic oxidizer and filter are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com