A double-shaft shoulder stirring head with automatic gap adjustment

An automatic adjustment and stirring head technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problem that the single-shaft shoulder stirring head cannot meet the requirements of the manufacturing process, so as to reduce welding heat input, improve mechanical properties, The effect of reducing welding spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

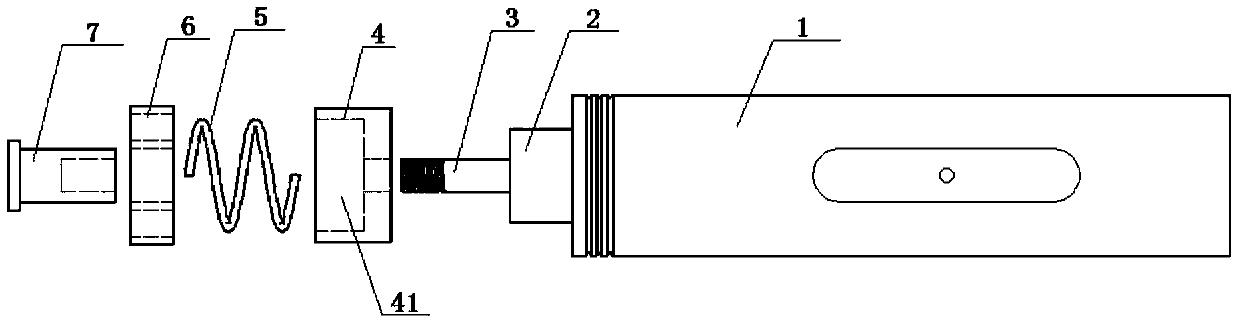

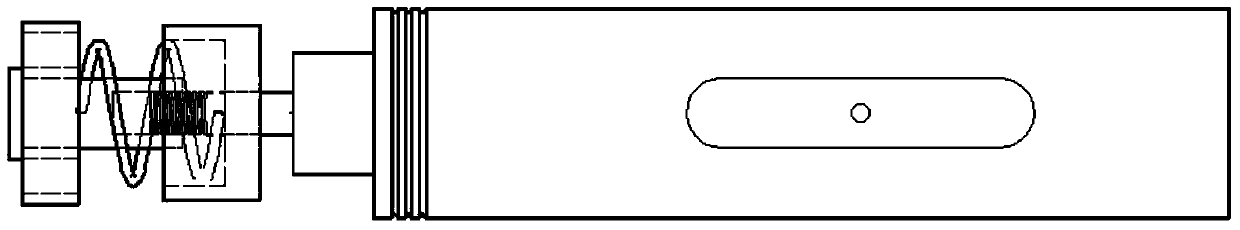

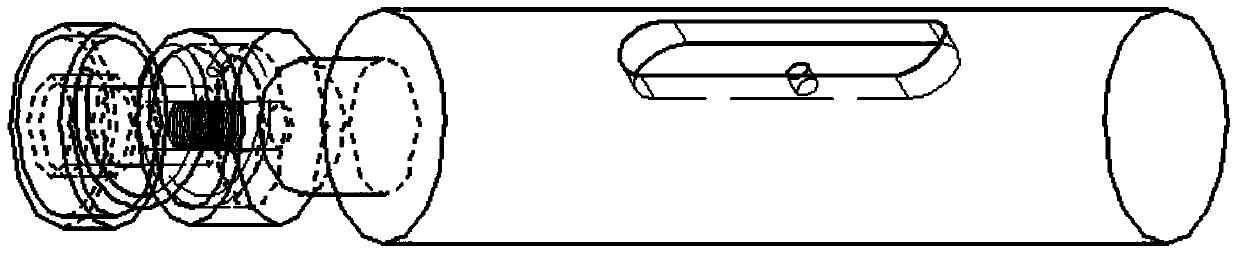

[0018] The dual-shaft shoulder stirring head with automatic clearance adjustment is constituted as follows: the stirring head main body 1, the upper shoulder 2, the stirring needle 3, the lower shoulder 4, the spring 5, the bearing 6 and the chassis 7; The power equipment is connected, and the stirring needle 3 is connected with the main body of the stirring head through the upper shoulder 2 to form an integrated structure. The lower end of the stirring needle 3 is provided with a thread structure, and the chassis 7 is a pin-shaped structural member as a whole, and the rod-shaped structure of the chassis 7 The upper end is processed with an internal thread structure, the stirring needle 3 is connected with the chassis 7 through a thread structure, the inner part of the lower shoulder 4 is provided with a T-shaped groove structure, and the lower shoulder 4 is set on the stirring needle through the T-shaped groove structure 41 3, the bearing 6 is sleeved on the chassis 7, one end...

Embodiment 2

[0025] The dual-shaft shoulder stirring head with automatic clearance adjustment is constituted as follows: the stirring head main body 1, the upper shoulder 2, the stirring needle 3, the lower shoulder 4, the spring 5, the bearing 6 and the chassis 7; The power equipment is connected, and the stirring needle 3 is fixedly connected with the lower end of the stirring head main body 1 through the upper shoulder 2, forming an integral structure. The lower end of the stirring needle 3 is provided with a threaded structure, the chassis 7 is a pin-shaped structural member as a whole, the upper end of the rod-shaped structure of the chassis 7 is processed with an internal thread structure, the stirring needle 3 and the chassis 7 are connected by a threaded structure, and the lower shoulder 4 There is a T-shaped groove structure inside, the lower shoulder 4 is set on the stirring needle 3 through the T-shaped groove structure 41, the bearing 6 is set on the chassis 7, and one end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com