A dual-focus laser micromachining device and its processing method

A micro-machining and double-focus technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of poor processing effect and low processing efficiency, increase processing efficiency, improve efficiency and effect, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

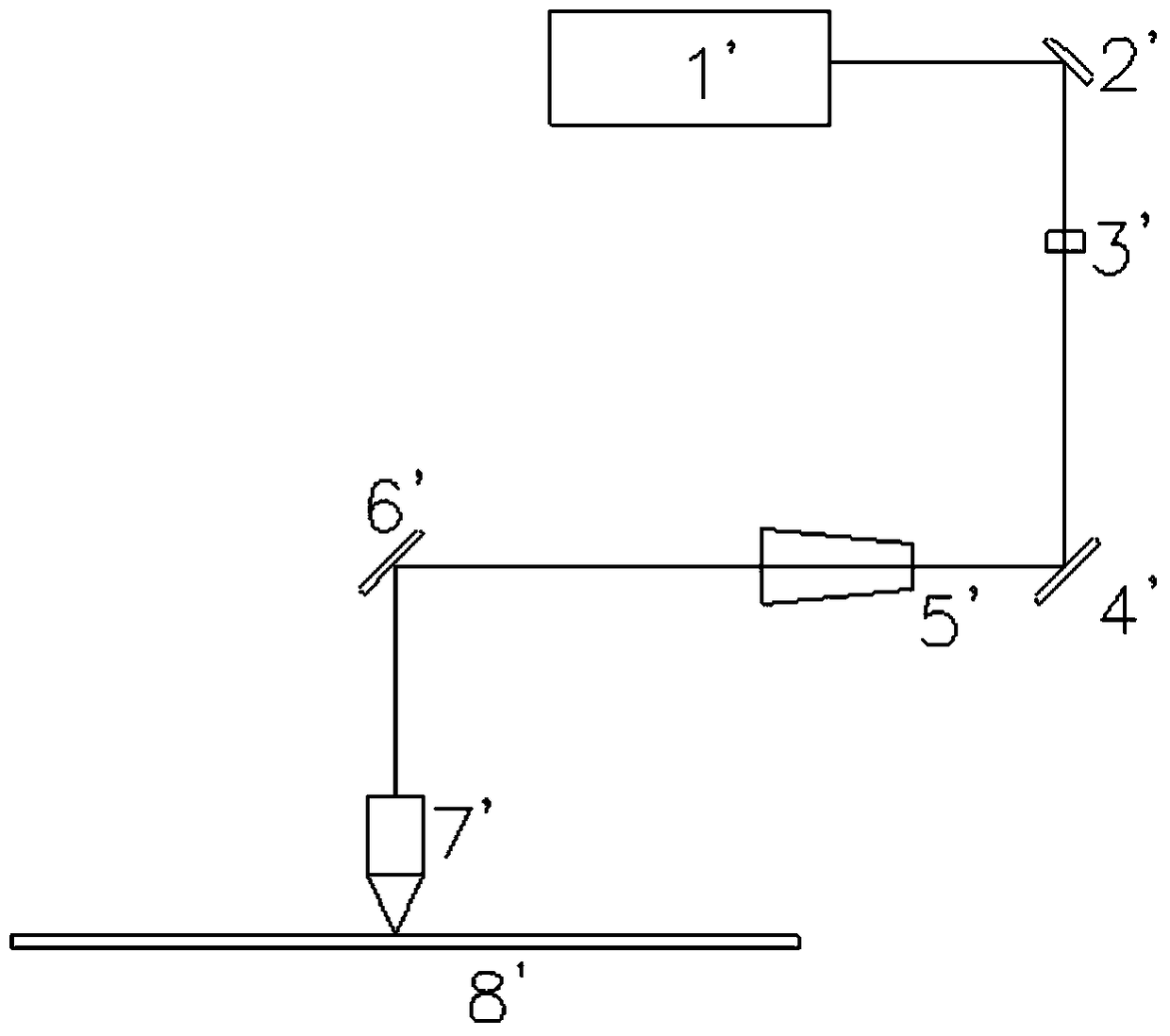

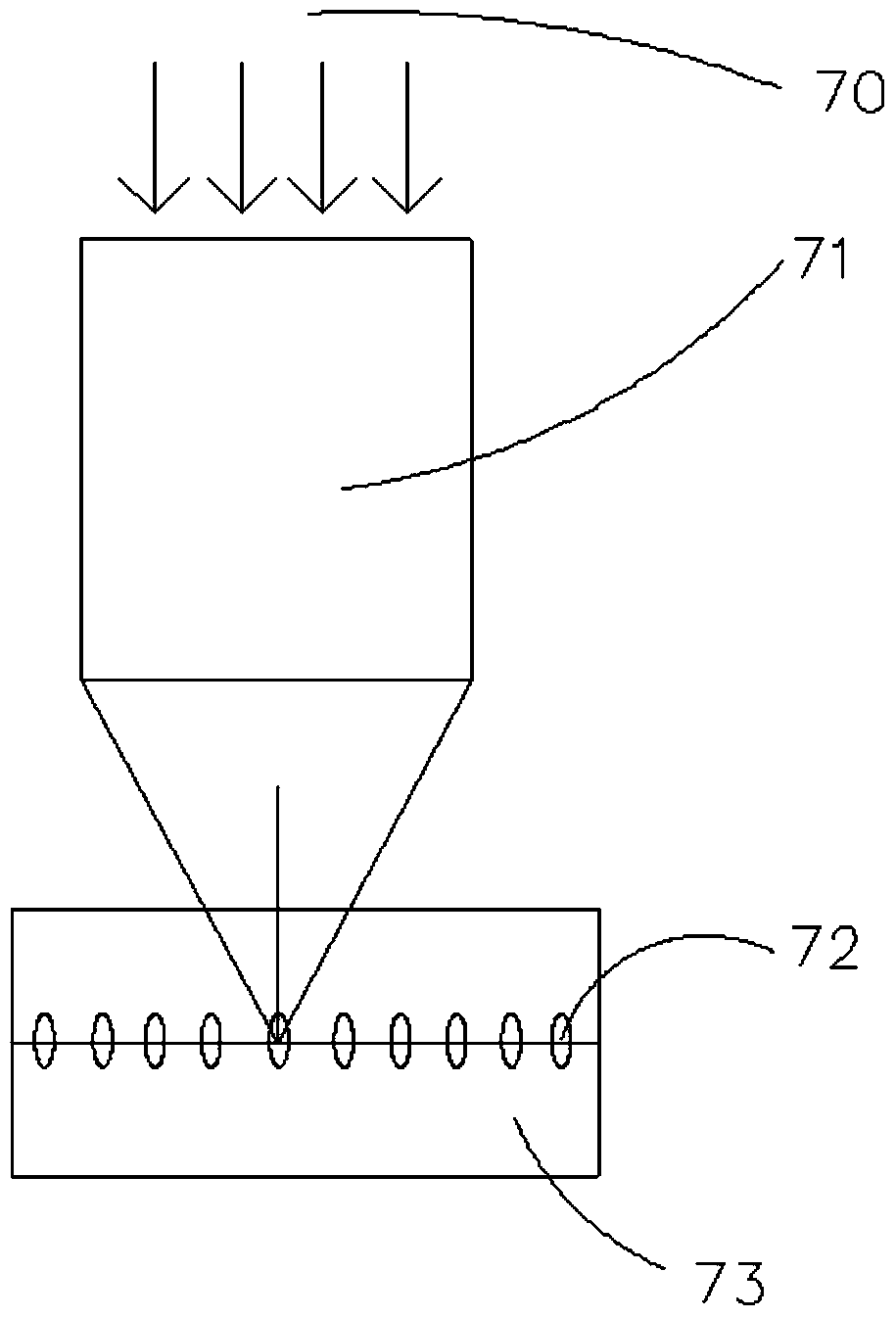

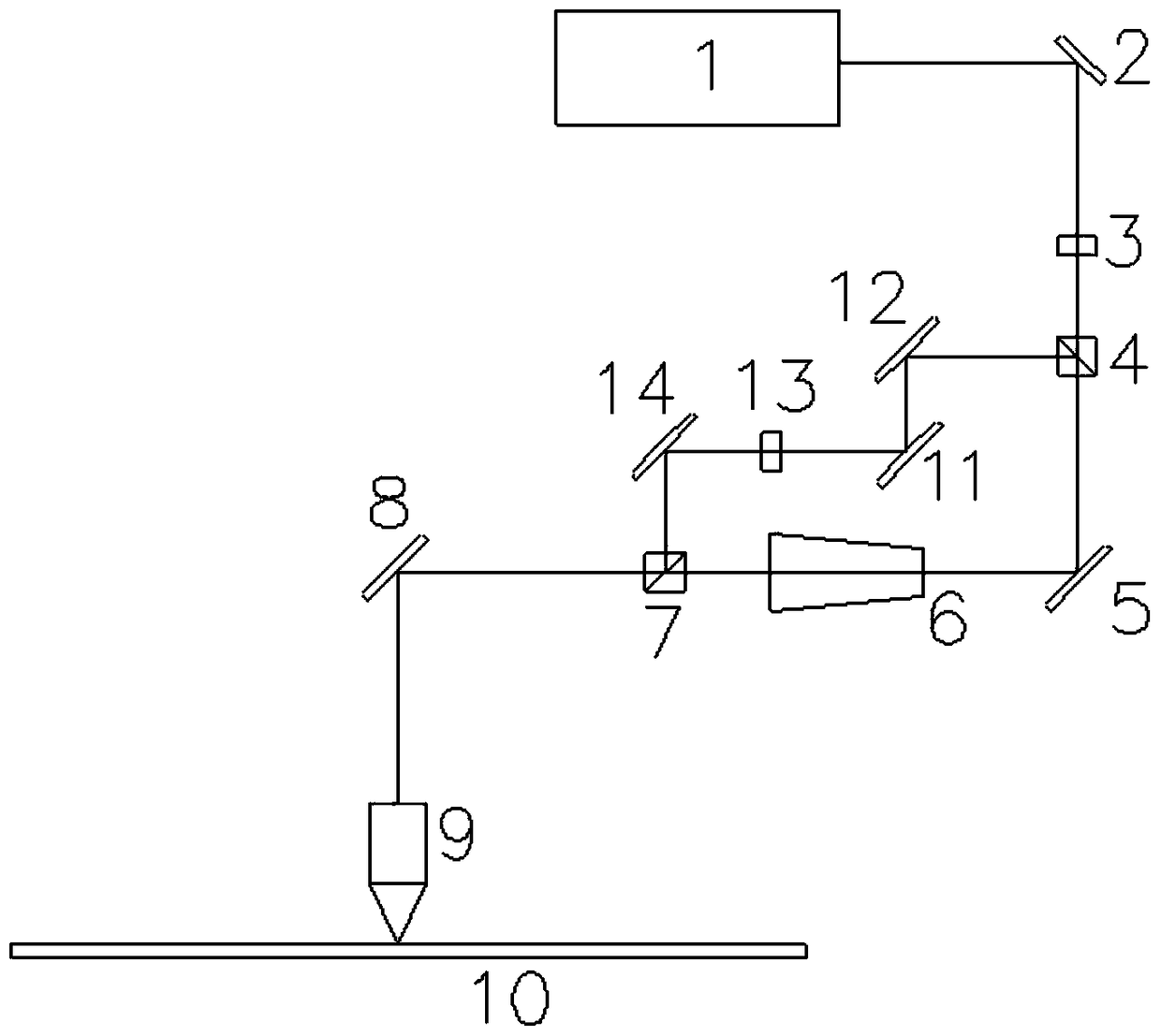

[0031] refer to Figure 3-Figure 4 As shown, the present invention provides a dual-focus laser micromachining device, including a laser 1, a first 45-degree reflector 2, a first half-wave plate 3, a third 45-degree reflector 8 and a focusing mirror 9, which are located at the first The output optical path of the half-wave plate 3 is used to divide the laser beam into the first polarizer 4 of the horizontally polarized beam P and the vertically polarized beam S, and the horizontal optical path device and the vertical optical path device respectively arranged on the horizontal polarized optical path and the vertical polarized optical path , the second polarizer 7 arranged at the output end of the horizontal optical path device and the output end of the vertical optical path device, the horizontally polarized light beam P passes through the horizontal polarized optical path, the second polarizer 7, the third 45-degree mirror 8 and the focusing mirror 9 in sequence Afterwards, the...

Embodiment 2

[0049] refer to image 3 , Figure 4 and Figure 5 As shown, the present embodiment also provides a dual-focus laser micromachining method, comprising the following steps,

[0050] The first step is to place the workpiece 10 under the focusing mirror 9. The workpiece 10 can be selected from glass, LED wafers, silicon wafers, semiconductors, etc.;

[0051] The second step is to turn on the laser 1 to emit a laser beam. The wavelength range of the laser beam is 355nm-1064nm, which can be other lasers such as ultraviolet, green, and infrared;

[0052] In the third step, the laser beam sequentially passes through the first 45-degree mirror 2, the first half-wave plate 3 and the first polarizer 4 to form a horizontally polarized beam P and a vertically polarized beam S;

[0053] Step 4: The horizontally polarized light beam P sequentially passes through the horizontally polarized optical path, the second polarizer 7, the third 45-degree mirror 8 and the focusing mirror 9 to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com