U-shaped tube accompanying tooling unit of a fin assembly automatic intubation system

A U-shaped tube and working unit technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor intensity of operators, low intubation efficiency, and inability to work at the same time, so as to achieve a high degree of equipment automation , Ensure that the work does not interfere with each other and avoid the effect of high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

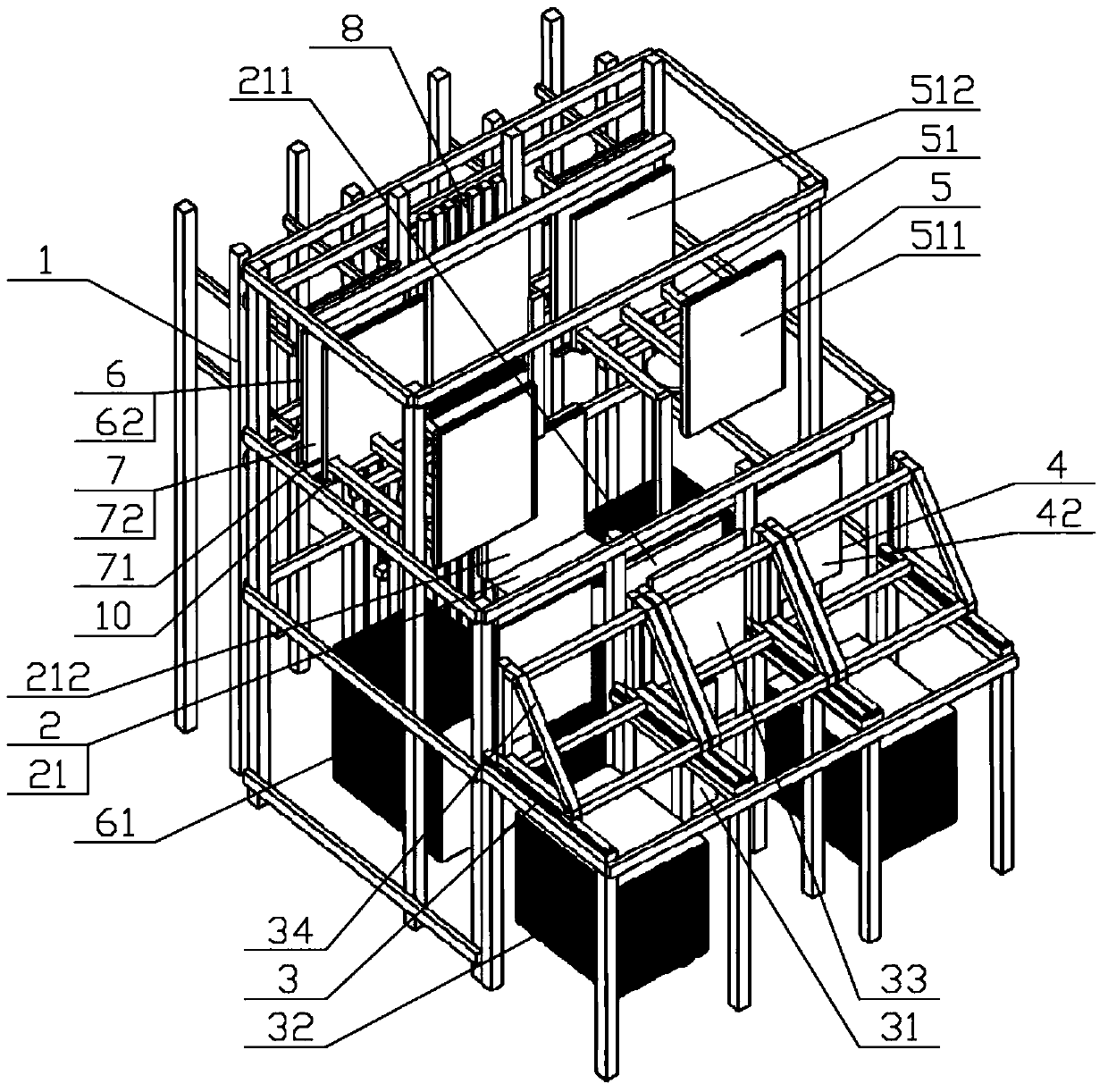

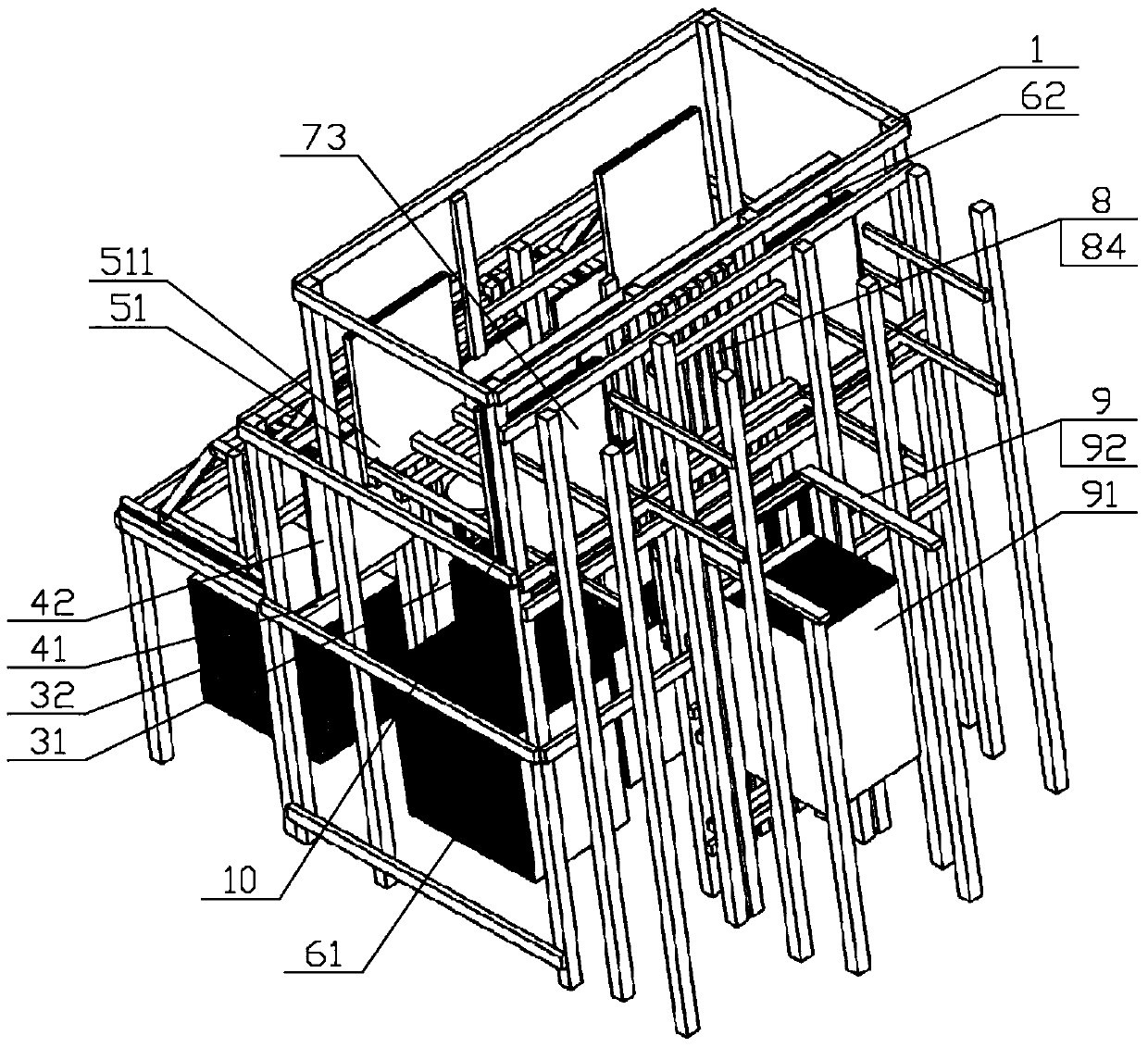

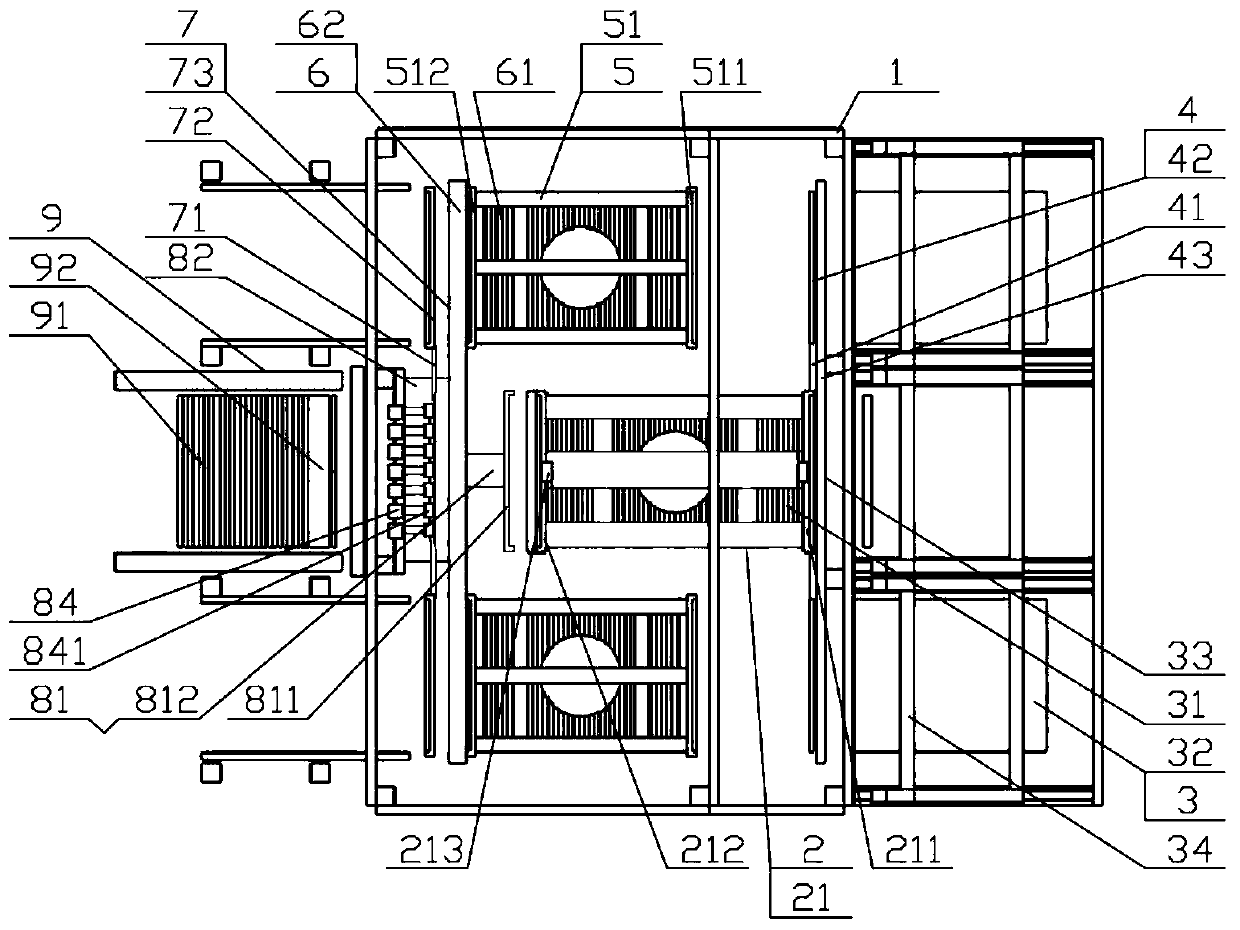

[0029] The present invention will be further described below in conjunction with the accompanying drawings (the following description takes the direction where the fin assembly grabbing and stacking unit 3 is located in the fin assembly long U-shaped tube automatic intubation system as the front).

[0030] Such as Figure 1 to Figure 6As shown, the U-shaped tube accompanying tooling unit 7 of the fin assembly automatic intubation system is arranged behind the U-shaped tube accompanying tooling indexing unit 5, including the U-shaped tube accompanying tooling rail 71, the U-shaped tube accompanying tooling 72 and U-shaped pipe accompanying frock grabbing and pushing device 73.

[0031] The U-shaped tube accompanying tool track 71 is arranged at the bottom of the upper rear part of the support frame 1, behind and below the U-shaped tube accompanying tool indexing work unit 5, and parallel to the working surface 512 after the U-shaped tube accompanying tool rotates. Arrangement,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com