An intubation unit for an automatic intubation system for a long U-shaped tube with fins

A U-shaped tube and fin technology, which is applied in the field of air conditioner manufacturing, can solve the problems of high labor intensity for operators, low intubation efficiency, and inability to work at the same time, so as to achieve a high degree of equipment automation, ensure that the work does not interfere with each other, Avoid labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

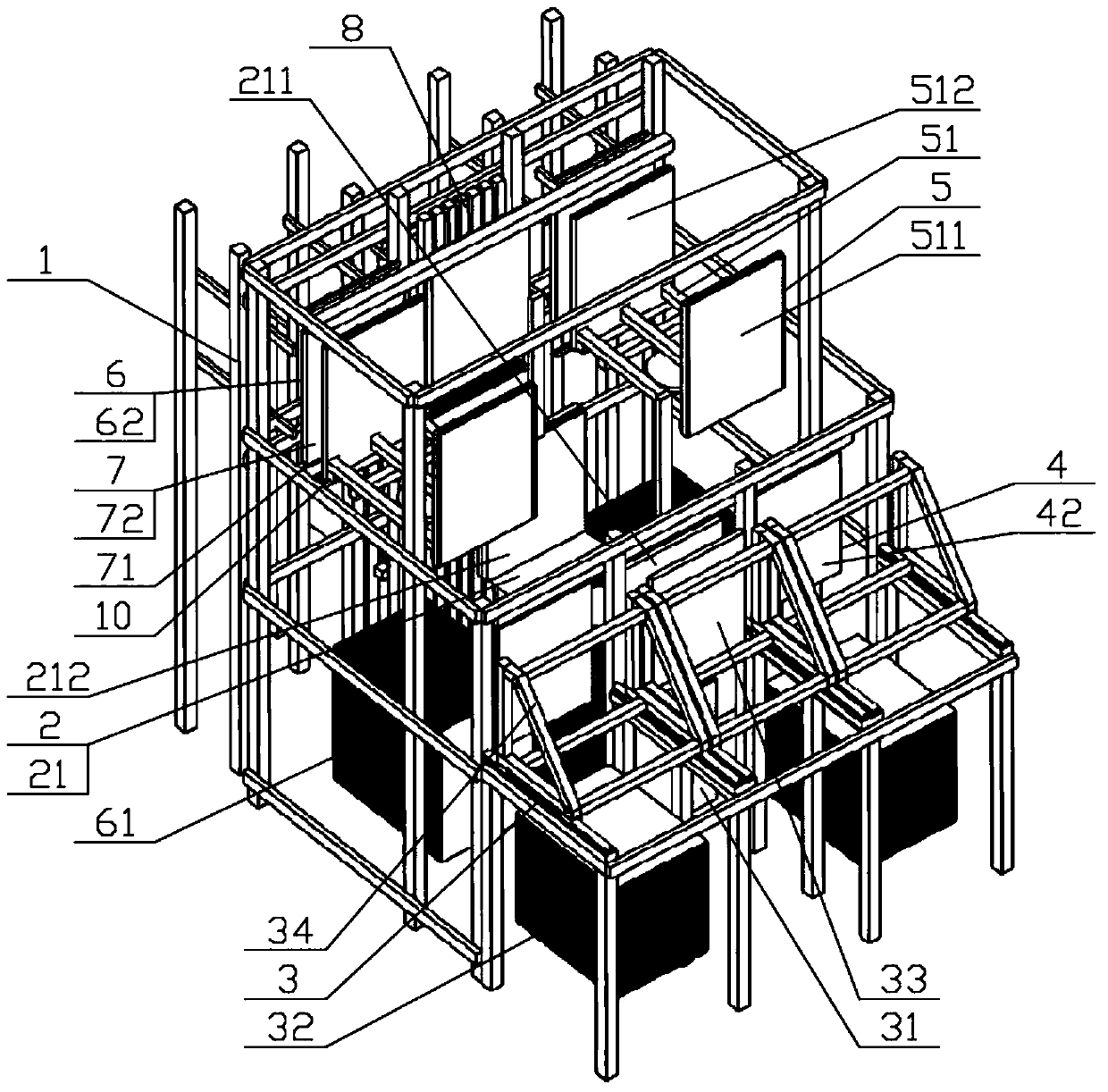

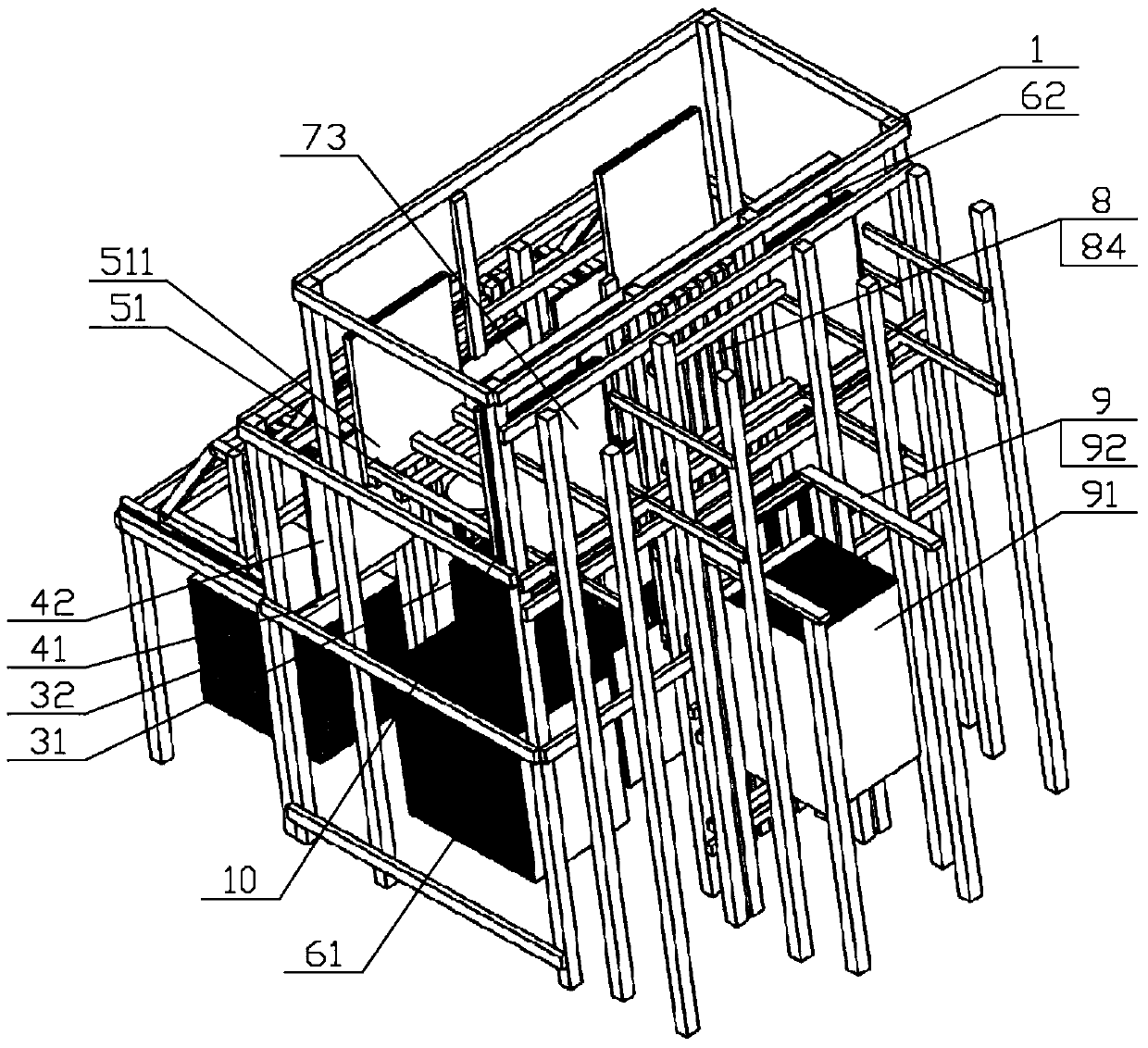

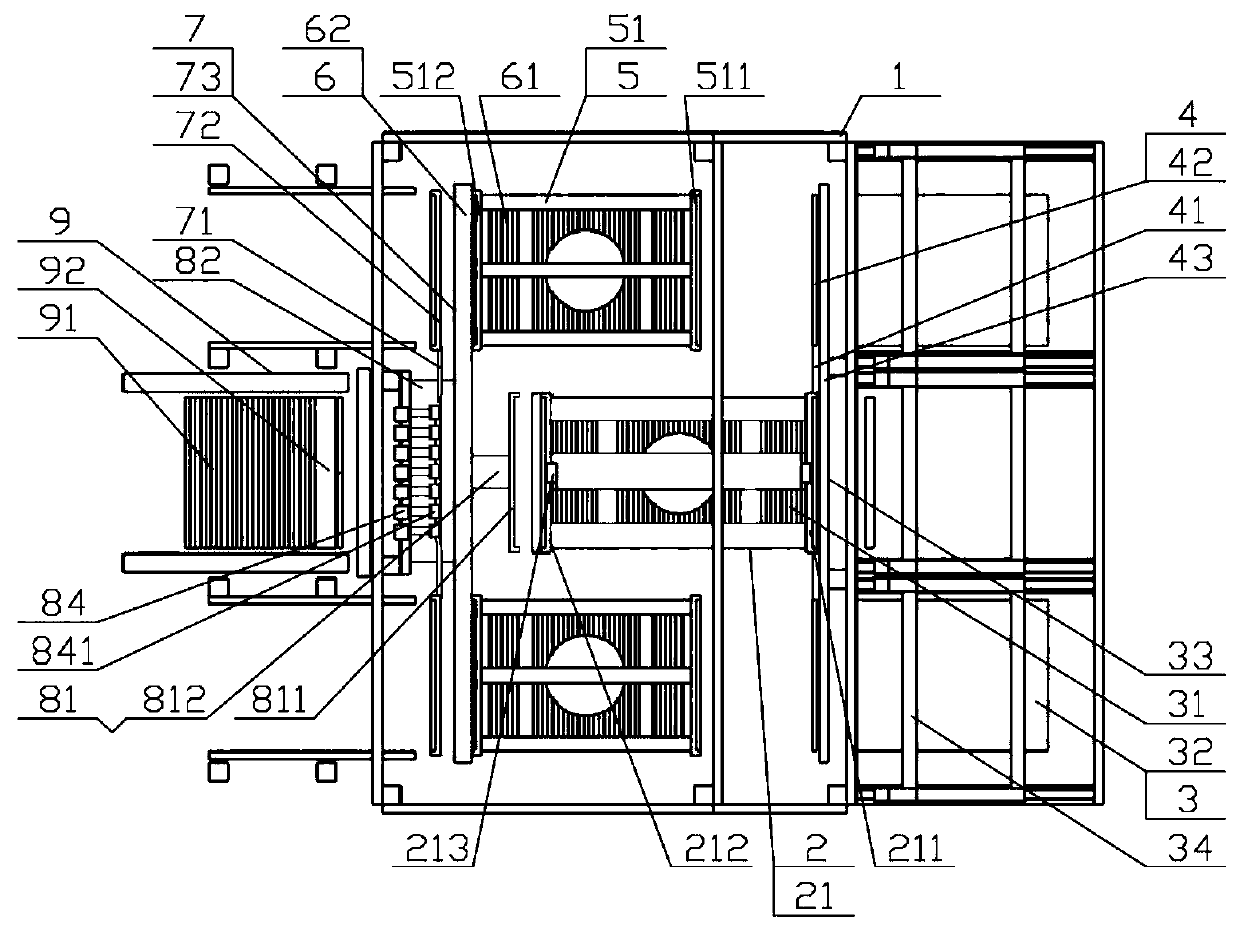

[0027]The present invention will be further described below in conjunction with the accompanying drawings (the following description takes the direction where the fin assembly grabbing and stacking unit 3 is located in the fin assembly long U-shaped tube automatic intubation system as the front).

[0028] like Figure 1 to Figure 4 As shown, the intubation unit 8 of the fin assembly long U-shaped tube automatic intubation system is arranged on the middle layer of the support frame 1, directly behind the fin assembly accompanying tooling indexing unit 2, including the fin assembly accompanying tooling Translate the grasping device 81 , the support platform 82 , the guide needle pushing device 83 and the intubation device 84 .

[0029] The fin assembly accompanying tool translation grabbing device 81 includes a positioning clamp 811 and a coordinate control translation mechanism 812. The positioning clamp 811 is a vertically arranged vertical plate frame structure, located on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com