Circular tube machining fixing structure

A technology for fixing structures and round tubes, applied in metal processing equipment, metal processing machinery parts, clamping, etc., can solve problems such as poor fixation and poor processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

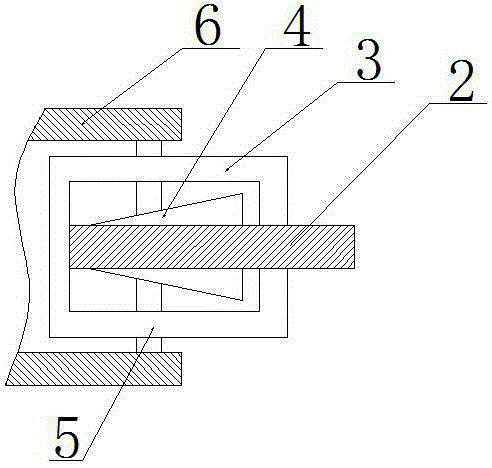

[0010] figure 1 Shown is the round pipe processing and fixing structure provided by the present invention, including a tie rod 2 , a roller 3 , a triangular column 4 and a slider 5 . The inside of the drum 3 is a cavity, and the outer surface of the drum 3 is provided with three through holes, the three through holes are evenly distributed, and the plane formed by the center lines of the three through holes is perpendicular to the axis of the drum 3; There is a pull rod 2, and a triangular column 4 is arranged on the pull bar 2. The plane parallel to the axis of the triangular column 4 and the drum 3 is an inclined surface, and each inclined surface is provided with a slider 5 that cooperates with the inclined surface, and the slider 5 is matched with the corresponding through hole. , and pass through the via.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com