Pneumatic gripper device

A pneumatic gripper and finger technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of inaccurate and stable grasping and releasing of workpieces, poor practical performance, cumbersome operation, etc., and achieve accurate and stable grasping and releasing of workpieces , low cost, good sports performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

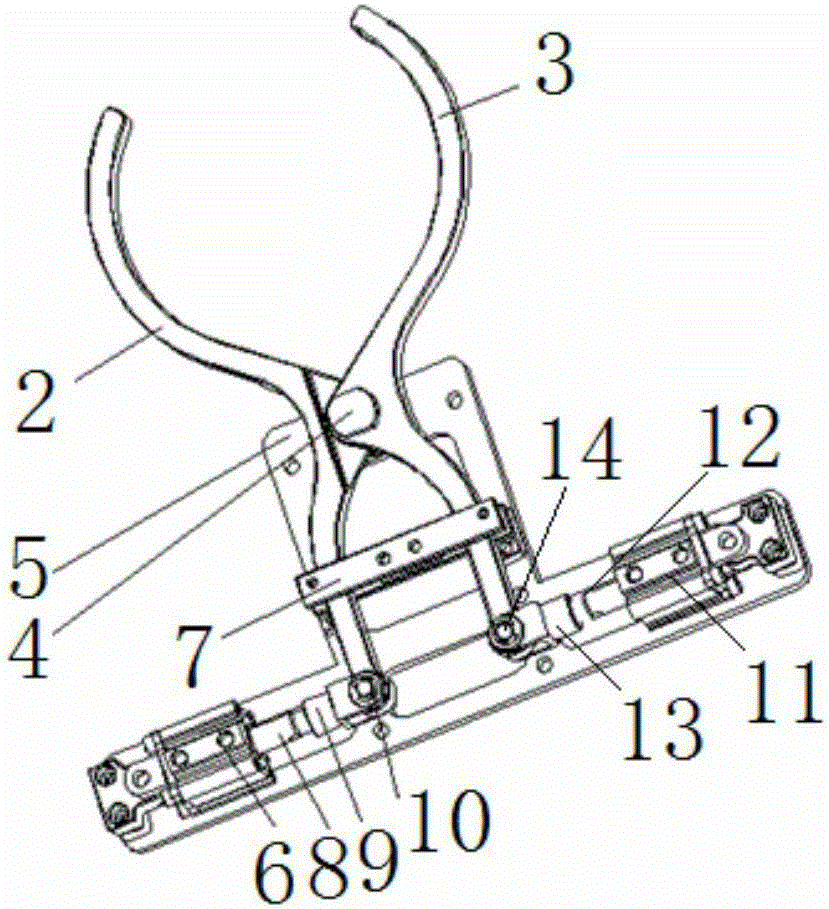

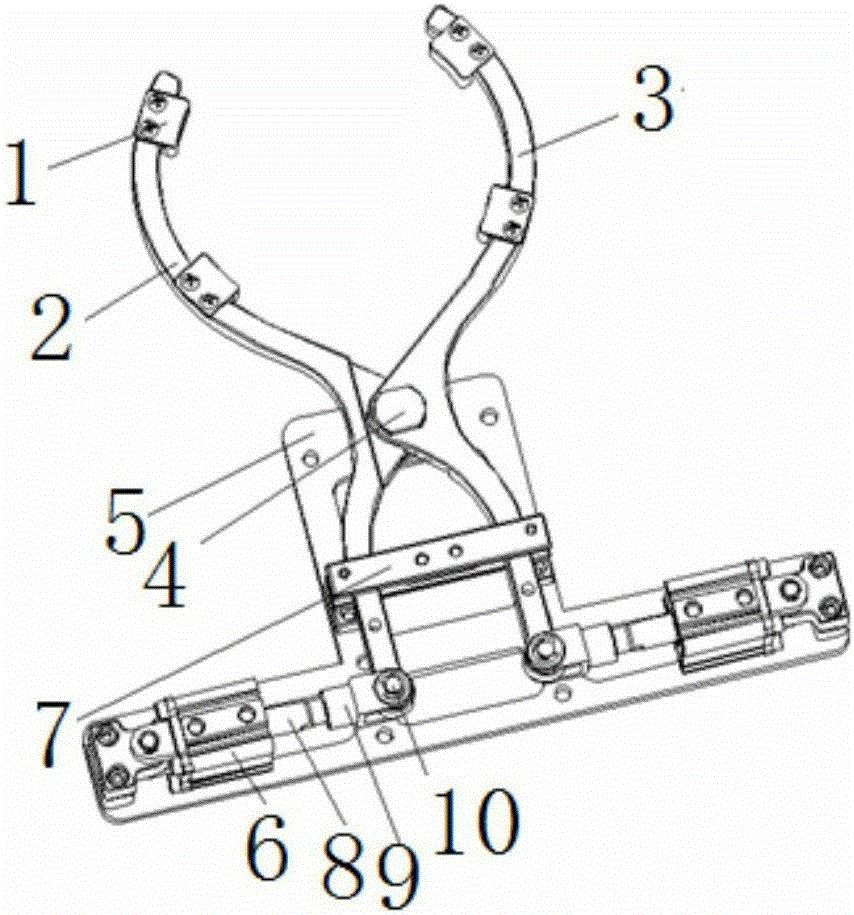

[0018] Such as figure 1 with figure 2 As shown, the pneumatic gripper device includes finger I2, finger II3, finger shaft 4, fixed mounting plate 5, cylinder I6, cylinder II11, and support plate 7, wherein the fixed mounting plate 5 is a T-shaped plate structure, and the finger shaft is set On the raised part of the T-shaped plate structure, the cylinder I and the cylinder II are respectively arranged on the two protruding ends of the T-shaped plate structure.

[0019] The finger I2 and the finger II3 are arranged oppositely, and the finger I and the finger II are hinged through the finger shaft 4 arranged on the fixed mounting plate.

[0020] Cylinder Ⅰ6 and cylinder Ⅱ11 are arranged oppositely, the end of piston rod Ⅰ8 of cylinder Ⅰ is connected with one end of connecting rod Ⅰ9, the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com