Injection molding production line for inorganic cement foaming insulation board

A cement foaming and insulation board technology, which is applied in cement mixing devices, mixing plants, clay preparation devices, etc., can solve the problems of insufficient structure of the production line, lagging production efficiency, large floor space, etc., and achieve reduction of plant investment, Reduced floor space and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

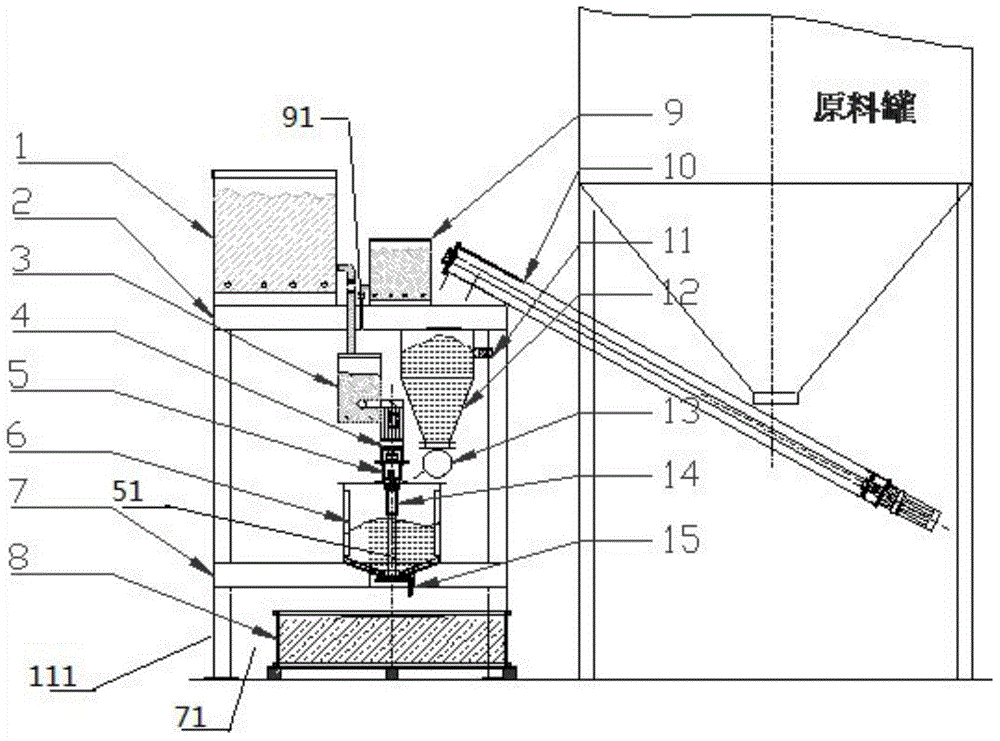

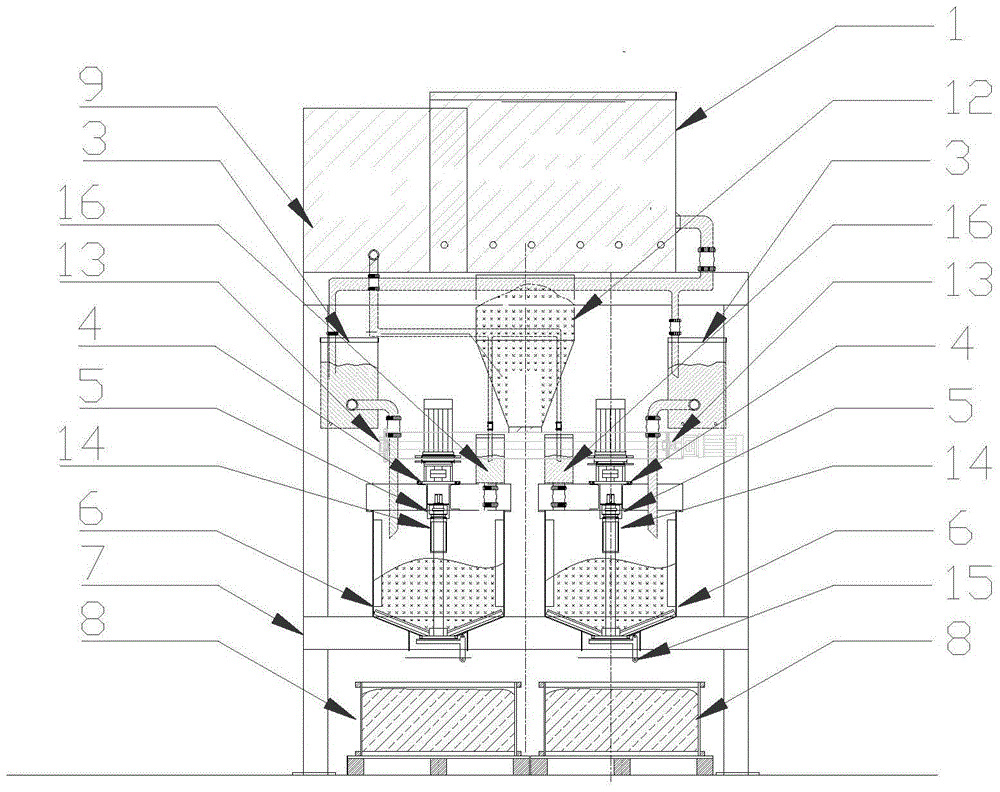

[0026] The invention relates to an injection molding production line of an inorganic cement foam insulation board, such as Figure 1~2 As shown: the production line consists of a housing 111, a constant temperature heating main water tank 1, two constant temperature heating distribution tanks 3, a foaming water storage tank 9 set in the housing 111, and 2 distribution foaming water tanks 16 set in the housing 111 , batching system, equipment support platform set in the shell 111, 2 sets of mixing systems set in the shell 111 and 2 sets of grinding tools 8 set in the shell 111, such as figure 1As shown: the equipment support platform includes a first-level support platform 7 and a second-level...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap