Combined dynamic control system and method for series-parallel automobile electrophoretic coating conveying mechanism

A conveying mechanism and electrophoretic coating technology, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as large shocks and long periods of time, and achieve improved real-time performance, enhanced robustness, and The effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

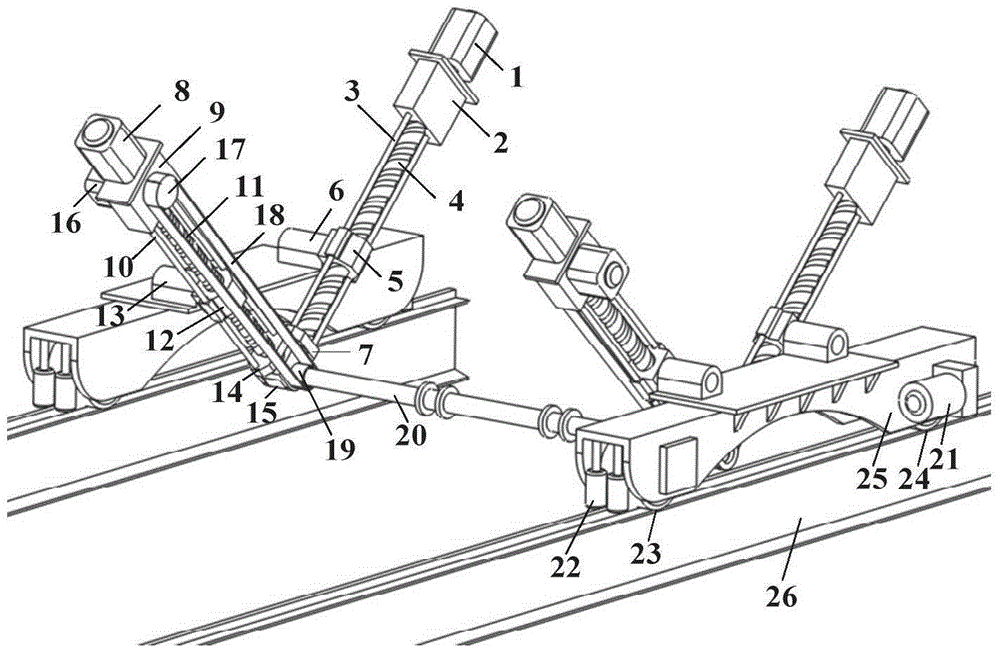

[0067] figure 1 The mechanism is a hybrid automobile electrophoretic coating conveying mechanism, which includes two functional parts: a walking mechanism and a lifting and turning mechanism. Wherein, the walking mechanism realizes the walking transportation function of the conveying mechanism through the cooperation of the walking driver 21, the guide wheel 22, the traveling wheel 23, the traveling wheel 24 and the guide rail 26. The frame of the lifting and turning mechanism is the moving part of the walking mechanism, and the lifting and turning mechanism is mainly composed of two groups of identical plane multi-rod mechanisms. The planar multi-bar mechanism includes three branches, wherein the first branch includes: the first driver 1, the first reducer 2, the first guide rail 3, the first lead screw 4, the first nut 5, the first rotating Auxiliary 6 and first screw seat 7; the first driver 1 is fixed on the first reducer 2, the first guide rail 3, the first screw seat 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com