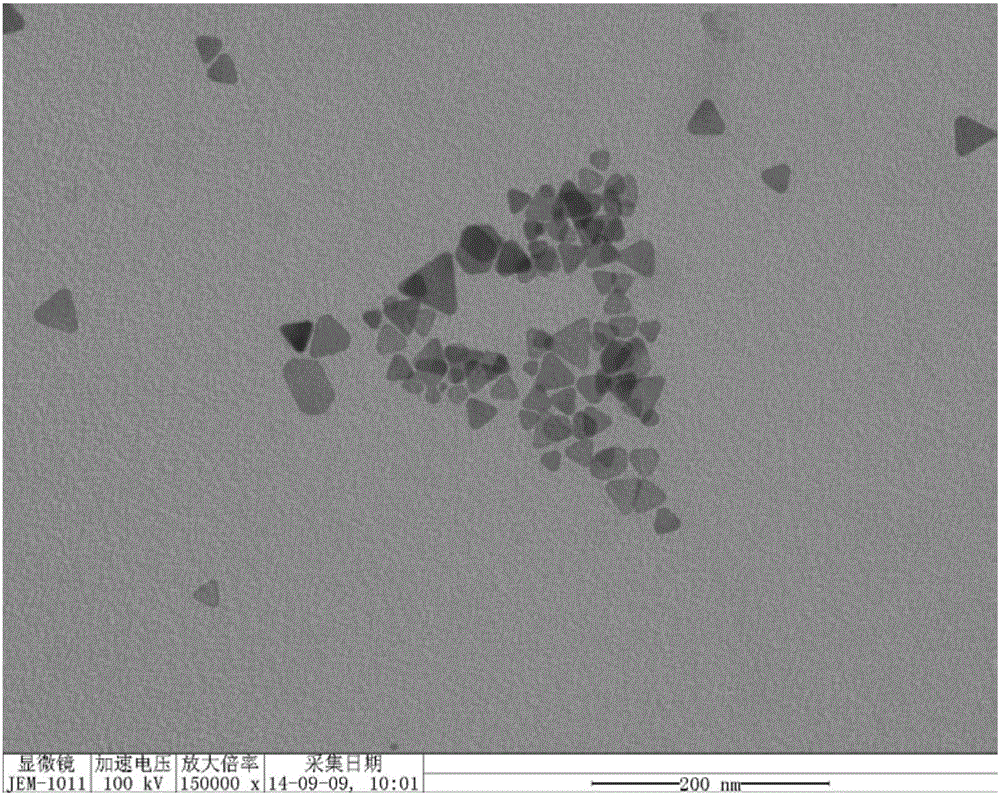

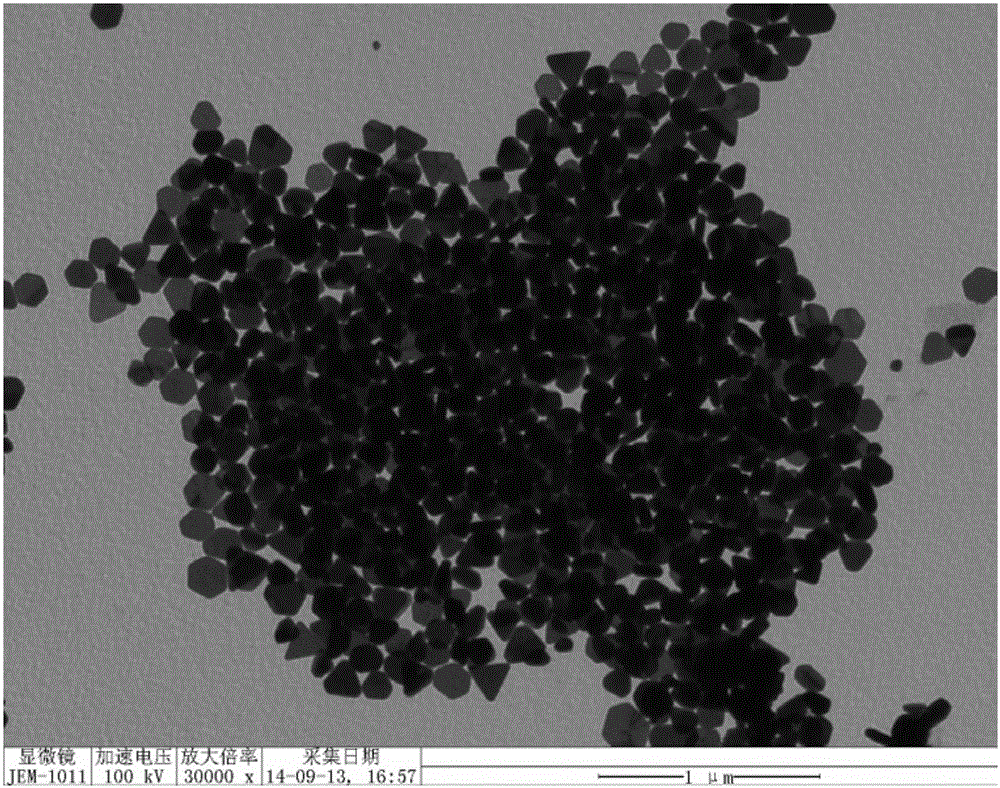

Macro-scale preparation method of monodisperse silver nanosheets

A silver nanosheet, monodisperse technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as unfavorable macro-preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for the macro preparation of monodisperse silver nanosheets, the steps are as follows:

[0039] (1) Add 0.222g of PVP to 50mL silver nanosheet seed crystal suspension, stir and dissolve at 30°C, add 0.13134g of C 6 h 8 o 7 , forming a homogeneous mixed solution;

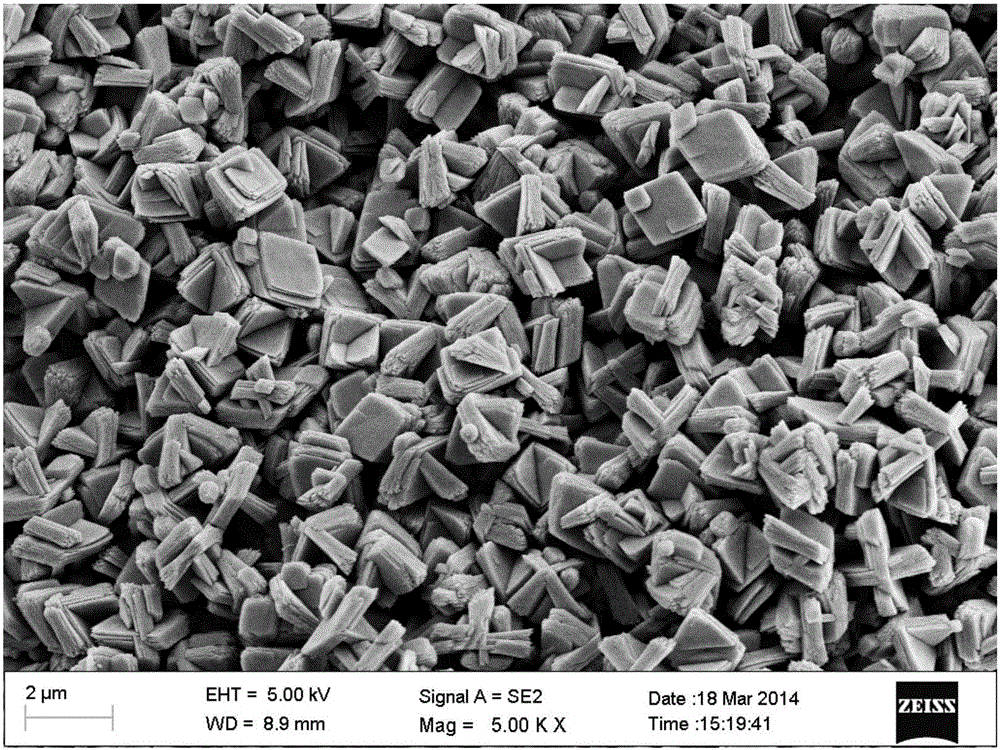

[0040] (2) Combine PVP and NH 4 Add SCN to water and stir evenly, the molar ratio of PVP to water is 1:50, NH 4 The molar ratio of SCN to water is 1:350; then add AgNO with a concentration of 10 g / L at a rate of 5 mL / min in a water bath at 45 °C 3 Aqueous solution, AgNO 3 with NH 4 The molar ratio of SCN is 1:1, and the reaction is continued for 0.5h after the feeding is completed, the solid product is centrifuged at a rate of 8000r / min, and the solid product is washed with water for 4 times, and then dried in air at 90°C to obtain AgCNS crystals. granule, the AgCNS crystal grain is dispersed in water, is mixed with the AgCNS suspension that concentration is 45wt%, stand-by;

[0041] (3) Then ...

Embodiment 2

[0044] A method for the macro preparation of monodisperse silver nanosheets, the steps are as follows:

[0045] (1) Add 0.222g of PVP to 50mL silver nanosheet seed suspension, stir and dissolve at 30°C, then add 0.13134g of C 6 h 8 o 7 , forming a homogeneous mixed solution;

[0046] (2) Combine PVP and NH 4 Add SCN to water and stir evenly, the molar ratio of PVP to water is 1:50, NH 4 The molar ratio of SCN to water is 1:350; then add AgNO with a concentration of 10 g / L at a rate of 5 mL / min in a water bath at 45 °C 3 Aqueous solution, AgNO 3 with NH 4 The molar ratio of SCN is 1:1, and the reaction is continued for 0.5h after the feeding is completed, the solid product is centrifuged at a rate of 8000r / min, and the solid product is washed with water for 4 times, and then dried in air at 90°C to obtain AgCNS crystals. granule, the AgCNS crystal grain is dispersed in water, is mixed with the AgCNS suspension that concentration is 45wt%, stand-by;

[0047] (3) Then add...

Embodiment 3

[0050] A method for the macro preparation of monodisperse silver nanosheets, the steps are as follows:

[0051] (1) Add 0.222g of PVP to 50mL silver nanosheet seed suspension, stir and dissolve at 30°C, then add 0.13134g of C 6 h 8 o 7 , forming a homogeneous mixed solution;

[0052] (2) Combine PVP and NH 4 Add SCN to water and stir evenly, the molar ratio of PVP to water is 1:60, NH 4 The molar ratio of SCN to water is 1:250; then add AgNO with a concentration of 15 g / L at a rate of 1 mL / min in a water bath at 30 °C 3 Aqueous solution, AgNO 3 with NH 4 The molar ratio of SCN is 1:1. Continue to react for 1 hour after the addition is complete, centrifuge the solid product at a rate of 3000r / min, wash the solid product with water for 3 times, and then dry it in the air at 60°C to obtain AgCNS grains , dispersing the AgCNS crystal grains in water, and preparing a AgCNS suspension with a concentration of 45wt%, for use;

[0053] (3) Then add 0.04mL of the AgCNS suspensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com