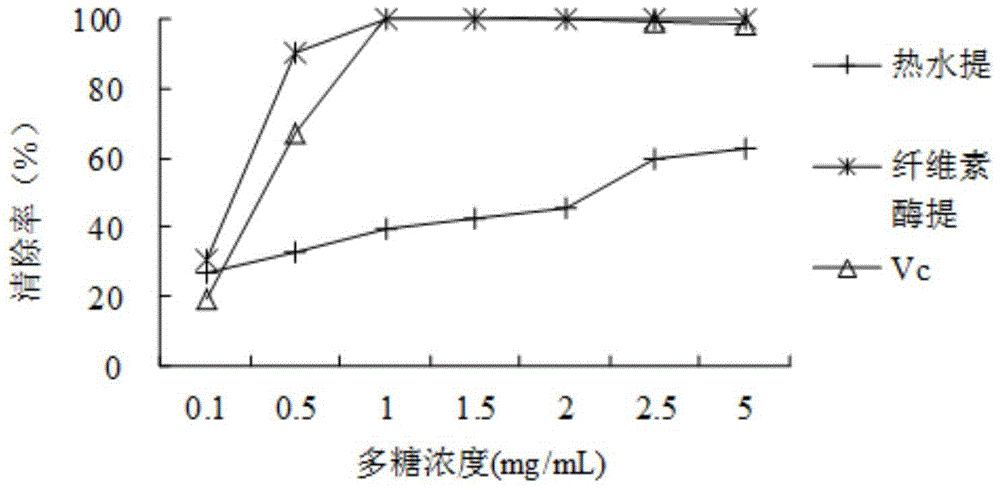

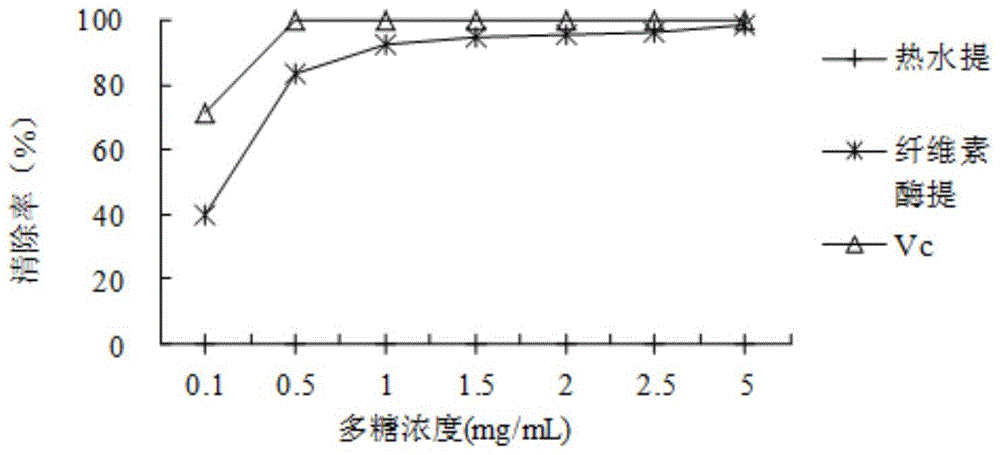

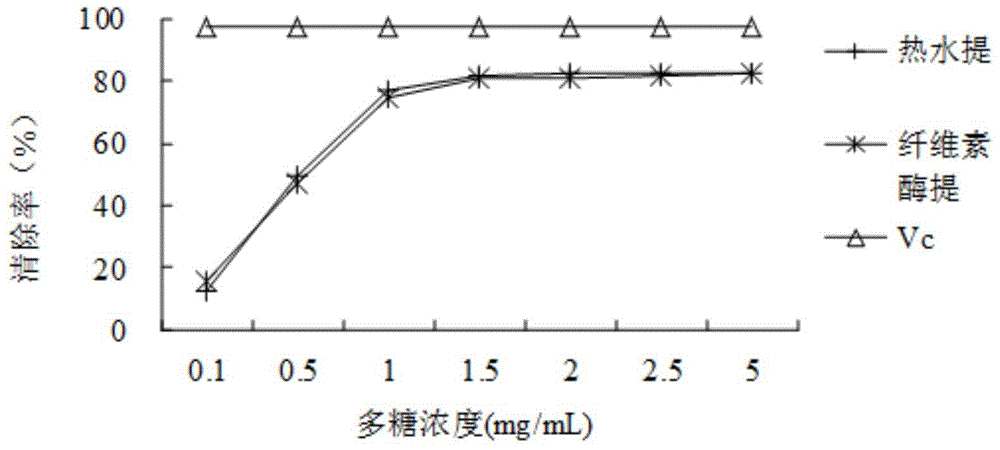

A high-efficiency extraction and separation process of anti-oxidative straw mushroom polysaccharides

An anti-oxidation and straw mushroom technology, applied in the direction of anti-virus, drug combination, etc., to achieve the effect of easy operation, simple process route, and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A high-efficiency extraction and separation process of anti-oxidation straw mushroom polysaccharide, the process comprises the following steps:

[0032] 1) Straw mushroom pretreatment: drying straw mushrooms to obtain dried straw mushrooms, and then degreasing to obtain defatted straw mushrooms;

[0033] 2) Pulverization: pulverize the defatted straw mushroom in step 1) to obtain straw mushroom powder, and the pulverization particle size is 40-80 mesh;

[0034] 3) Enzymatic extraction and enzyme inactivation: add 25 times the weight of water to the straw mushroom powder, then add 0.3% cellulase, keep the temperature of the material at 50°C, stir, and maintain the temperature for 120 minutes, then raise the temperature of the material to 90°C ℃, maintain 10min inactivation and then use the obtained material for later use;

[0035] 4) Centrifugation: cool the material in step 3) to 20°C, centrifuge at a speed of 3000r / min, and centrifuge for 10min, discard the precipitat...

Embodiment 2

[0044] A high-efficiency extraction and separation process of anti-oxidation straw mushroom polysaccharide, the process comprises the following steps:

[0045] 1) Straw mushroom pretreatment: drying straw mushrooms to obtain dried straw mushrooms, and then degreasing to obtain defatted straw mushrooms;

[0046] 2) Pulverization: pulverize the defatted straw mushroom in step 1) to obtain straw mushroom powder, and the pulverization particle size is 40-80 mesh;

[0047] 3) Enzymatic extraction and enzyme inactivation: add water 30 times the weight of straw mushrooms to the straw mushroom powder, then add 0.35% cellulase, keep the temperature of the material at 55°C, stir, and after maintaining the temperature for 90 minutes, raise the temperature of the material to 100 ℃, maintain for 5 minutes and inactivate the obtained material for later use;

[0048] 4) Centrifugation: Cool the material in step 3) to 40°C, centrifuge at a speed of 4000r / min, and centrifuge for 5min, discard...

Embodiment 3

[0053] A high-efficiency extraction and separation process of anti-oxidation straw mushroom polysaccharide, the process comprises the following steps:

[0054] 1) Straw mushroom pretreatment: drying straw mushrooms to obtain dried straw mushrooms, and then degreasing to obtain defatted straw mushrooms;

[0055] 2) Pulverization: pulverize the defatted straw mushroom in step 1) to obtain straw mushroom powder, and the pulverization particle size is 40-80 mesh;

[0056] 3) Enzymatic extraction and enzyme inactivation: add 27 times the weight of water to the straw mushroom powder, then add 0.33% cellulase, keep the temperature of the material at 53°C, stir, and maintain the temperature for 100 minutes, then raise the temperature of the material to 95 ℃, maintain for 8 minutes and inactivate the obtained material for later use;

[0057] 4) Centrifugation: Cool the material in step 3) to 30°C, centrifuge at a speed of 3500r / min, centrifuge for 7min, discard the precipitate, and ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com