Antique paint and preparation method thereof

A coating and slurry technology, applied in the field of antique coatings and their preparation, can solve problems such as being unable to be obtained naturally, and achieve the effects of saving raw material costs, avoiding loss, and improving corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

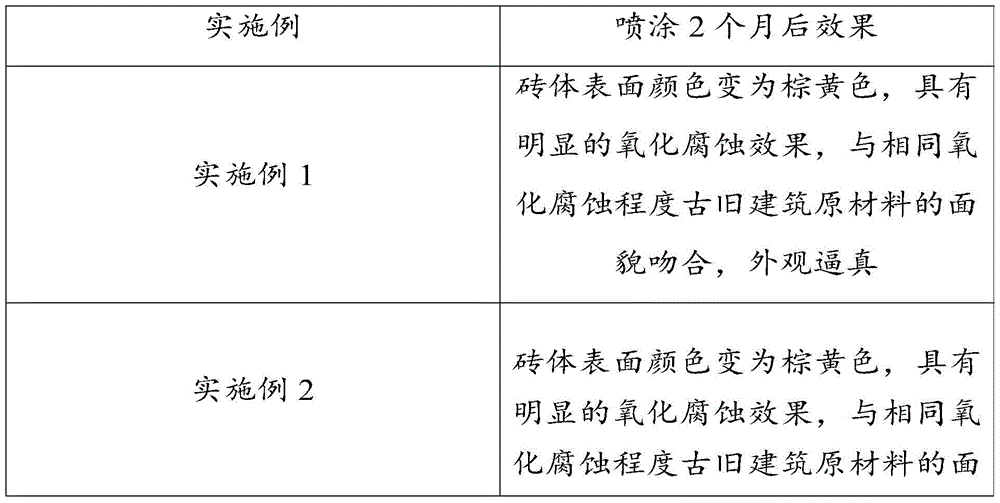

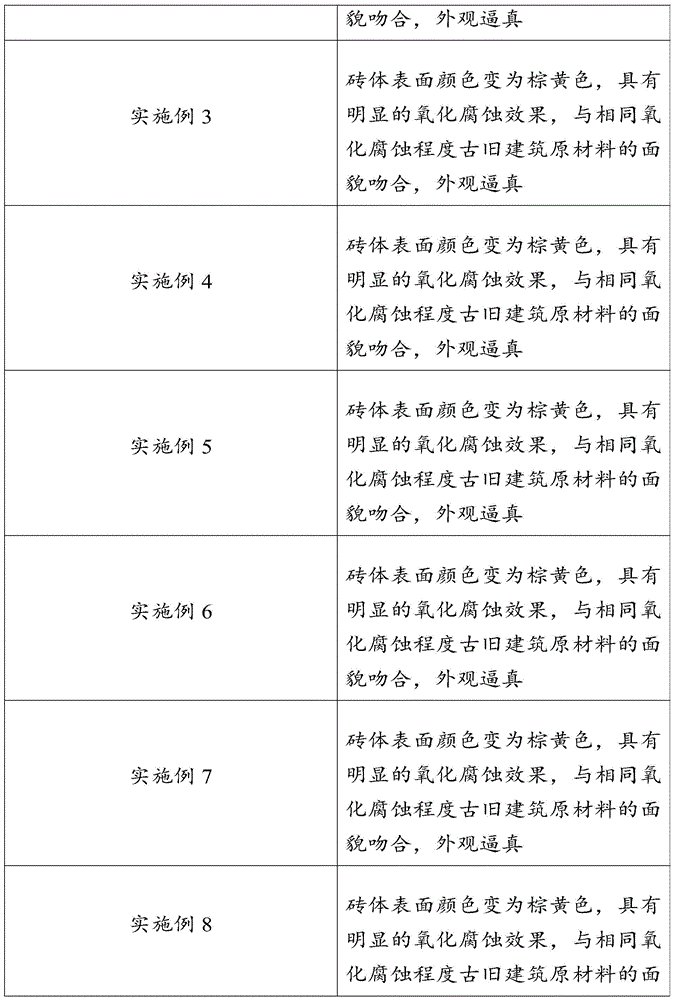

Examples

Embodiment 1

[0036] A preparation method for antique paint, comprising the steps of:

[0037] (1) In parts by mass, 0.1 part of LiOH, 0.1 part of Li 2 SO 4 Add 1 part of water respectively, heat and stir to dissolve and set aside;

[0038] (2) In parts by mass, 1 part of Al 2 (SO 4 ) 3 , 0.1 part of NaOH, and 0.5 part of NaCl were added to 5 parts of water respectively, heated and stirred evenly to obtain a brown-yellow mixture for subsequent use;

[0039] (3) Add 0.1 part of clay to the solution obtained in step (2), stir evenly, and obtain the slurry for subsequent use;

[0040] (4) Add 5 drops of the solution obtained in step (1) dropwise to the slurry obtained in step (3), and stir evenly to obtain an antique paint.

Embodiment 2

[0042] A preparation method for antique paint, comprising the steps of:

[0043] (1) In parts by mass, 1 part of LiOH, 1 part of Li 2 SO 4 Add 1-10 parts of water respectively, heat and stir to dissolve and set aside;

[0044] (2) In parts by mass, 1-3 parts of Al 2 (SO 4 ) 3 , 1 part of NaOH, and 1 part of NaCl were added to 15 parts of water respectively, heated and stirred evenly to obtain a brown-yellow mixture for subsequent use;

[0045] (3) Add 1 part of clay to the solution obtained in step (2), stir evenly, and obtain the slurry for subsequent use;

[0046] (4) Add 15 drops of the solution obtained in step (1) dropwise to the slurry obtained in step (3), and stir evenly to obtain an antique paint.

Embodiment 3

[0048] A preparation method for antique paint, comprising the steps of:

[0049] (1) In parts by mass, 0.3 parts of LiOH, 0.3 parts of Li 2 SO 4 Add 4 parts of water respectively, heat and stir to dissolve and set aside;

[0050] (2) In parts by mass, 1.5 parts of Al 2 (SO 4 ) 3 , 0.3 parts of NaOH and 0.6 parts of NaCl were added to 7 parts of water respectively, heated and stirred evenly to obtain a brownish-yellow mixture for subsequent use;

[0051] (3) Add 0.4 part of clay to the solution obtained in step (2), stir evenly, and obtain the slurry for subsequent use;

[0052] (4) Add 8 drops of the solution obtained in step (1) dropwise to the slurry obtained in step (3), and stir evenly to obtain an antique paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com