A kind of nickel-carbon-iron-based powder metallurgy alloy and preparation method thereof

An iron-based powder metallurgy and nickel-carbon technology, which is applied to powder metallurgy low-alloy steel with carbon elements and its preparation, increases the field of nickel, and can solve the problem that the plasticity of iron-based powder metallurgy materials has not been significantly improved and the factors affecting plasticity have not Relatively sufficient explanation and research, alloy plasticity has not been significantly improved, etc., to achieve the effect of good plasticity and microstructure that is conducive to popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

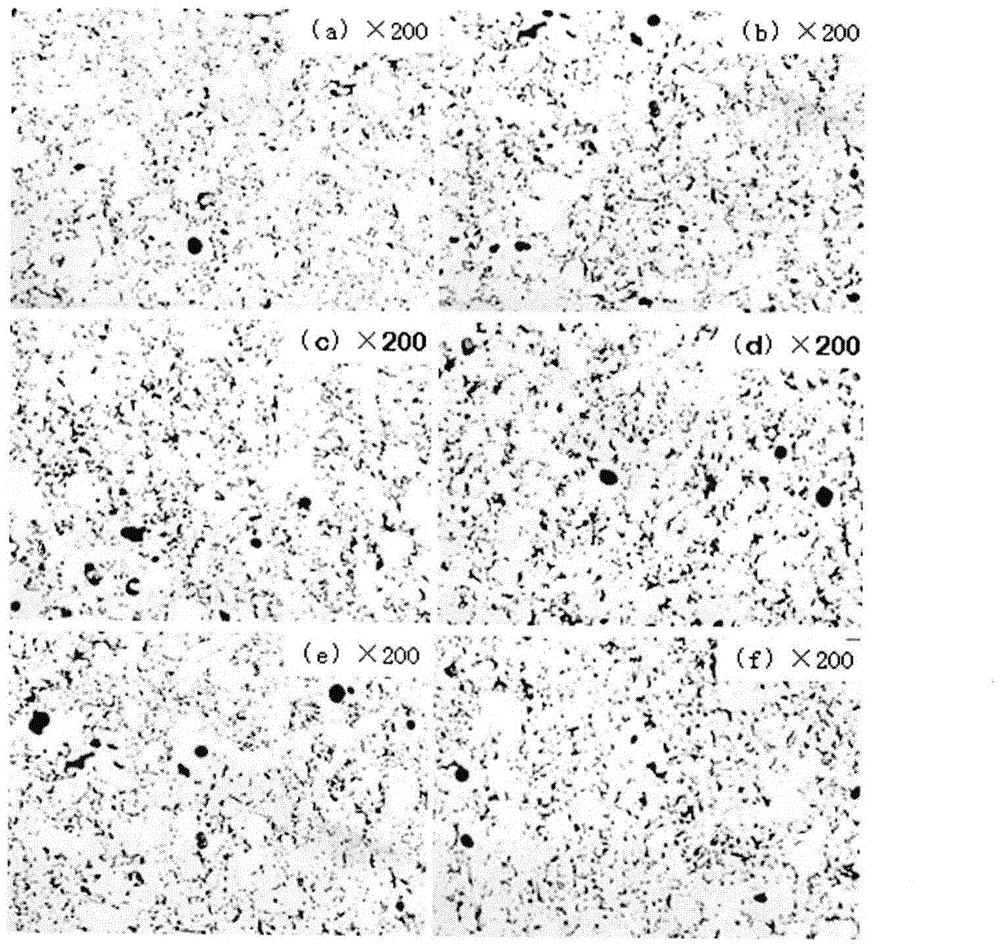

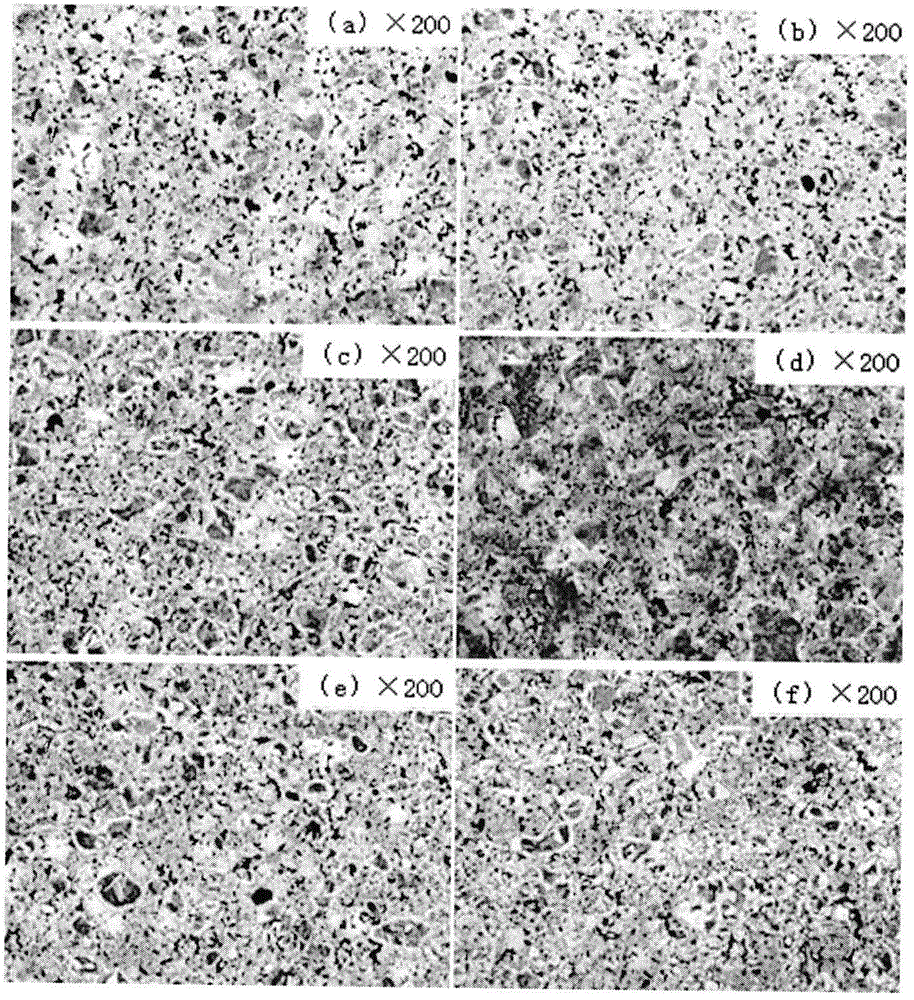

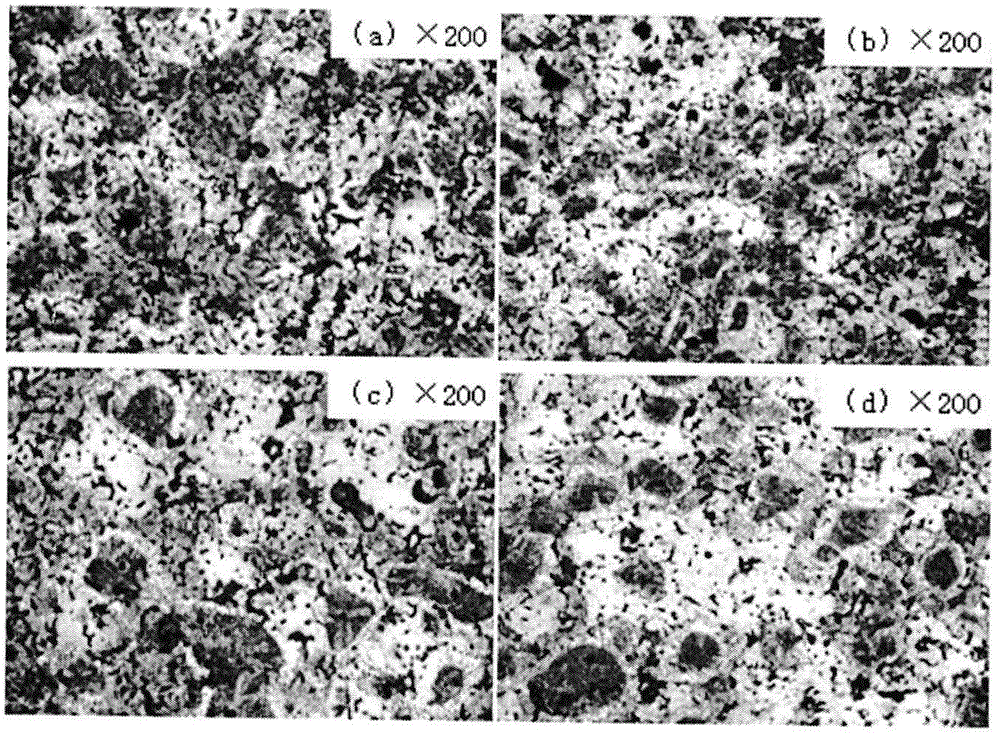

Image

Examples

Embodiment 1

[0032] (1) LAP100.29 water atomized iron powder is used as raw material, colloidal graphite and carbonyl nickel powder are used as raw materials for adding carbon and nickel alloying elements respectively, and nickel-carbon-iron-based materials are prepared according to the ratio in Table 1 (the balance is Iron), add zinc stearate (ZnSt 2 ) as a release agent.

[0033] (2) Ball milling and mixing: during mixing, 500g of the material in step (1) is used as a mixing batch, and the powder is milled using a horizontal ball mill. The material of the ball milling tank is stainless steel, and the steel ball material is stainless steel. The ball-to-material ratio is 2: 1. The rotating speed of the spherical tank is set to 200r / min, the ball milling time is 8 hours, and the protective atmosphere is not used.

[0034] (3) Put the material in step (2) into the mold and press to form.

[0035] (4) Bury the material in step (3) in the refractory sand in the sintering furnace, the sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com