Open-end Spinning Device With An Intermediate Chamber

An air-flow type, intermediate cavity technology, applied in the direction of continuous winding spinning machine, spinning machine, open-end spinning machine, etc., can solve problems such as failure of bearings and drives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

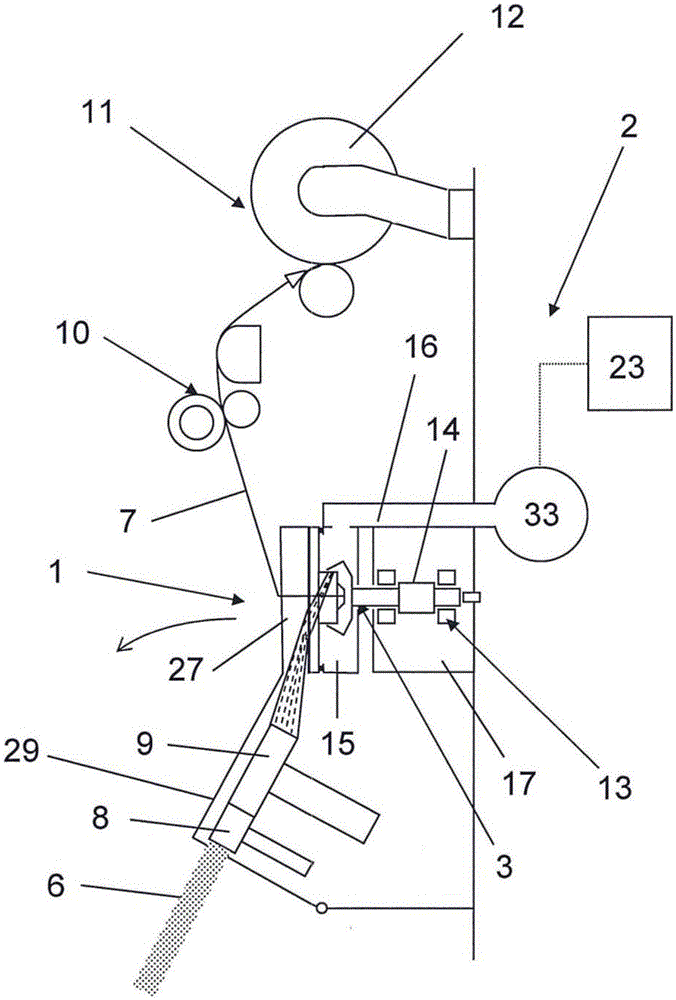

[0033] figure 1 A schematic view of an air spinning device 1 of a rotor spinning machine 2 is shown in a schematic side view. Rotor spinning machine 2 comprises feed device 8 in usual manner, and this feed device is passed loose device 9 ( The unraveling device) conveys the fiber material 6 into the air spinning device 1, and the loosening device 9 loosens the fiber material into individual fibers. In the air spinning device 1, the fiber material 6 is in the rotor cup of the spinning rotor 3 (see Figure 2-6 ) is spun into a yarn 7 and unwound by an unwinding device 10 and wound on a bobbin 12 by means of a winding device 11 .

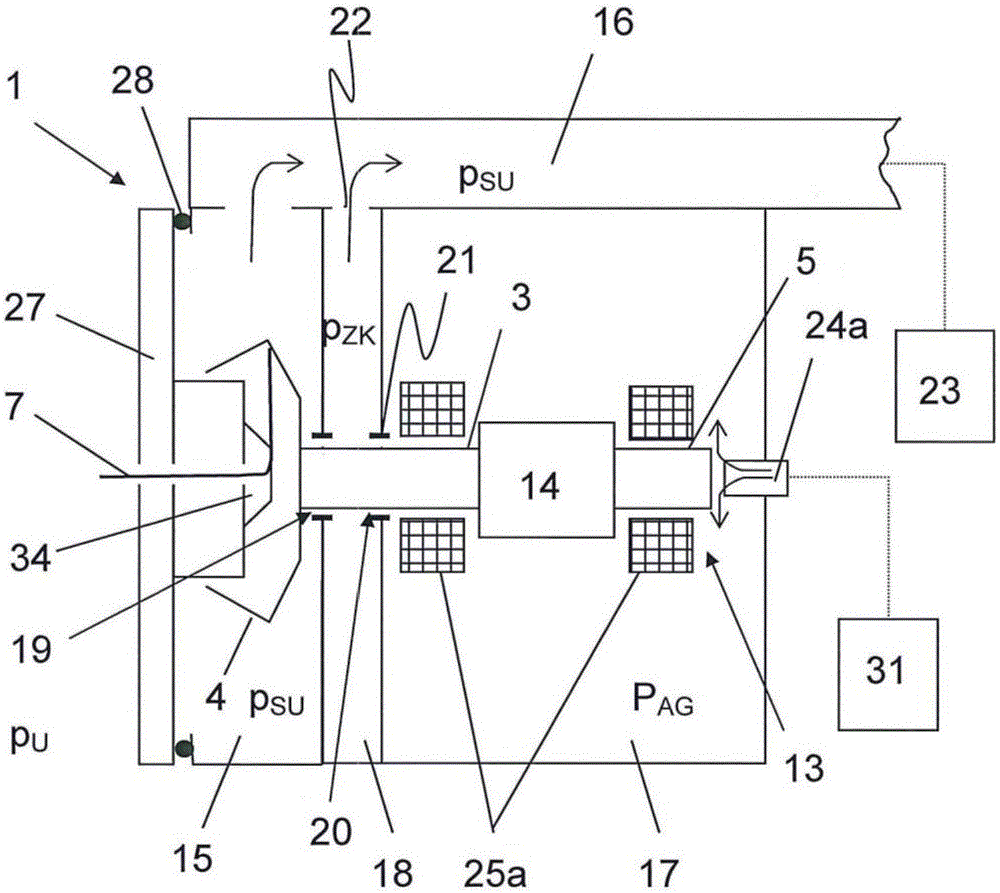

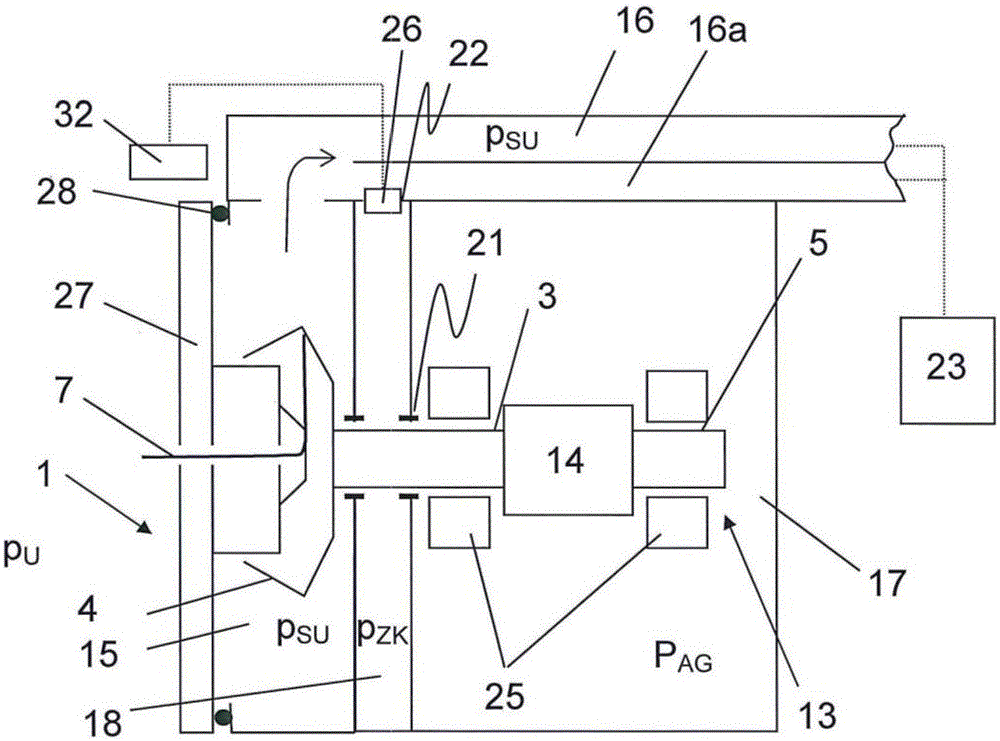

[0034] In addition to the spinning rotor 3 with rotor cup 4 and rotor rod 5 (see Figure 2-6 ), the pneumatic spinning device 1 also includes a rotor housing 15 and a driver housing 17, the rotor cup 4 is arranged in the rotor housing 15, and the rod 5 of the spinning rotor 3 extends in the driver housing 17. According to the present illustration,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com