Honeycomb-type air filtration yarn for doors and windows

An air filtration and air filtration material technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of inability to isolate fine particles, inability to achieve ventilation effect, inability to open windows for ventilation, etc., and achieve high air filtration efficiency. , The structure is simple, the effect of improving the filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

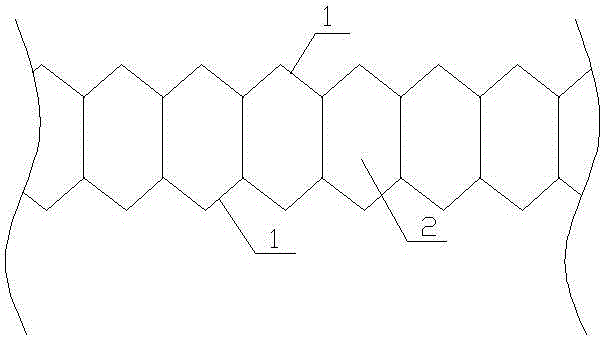

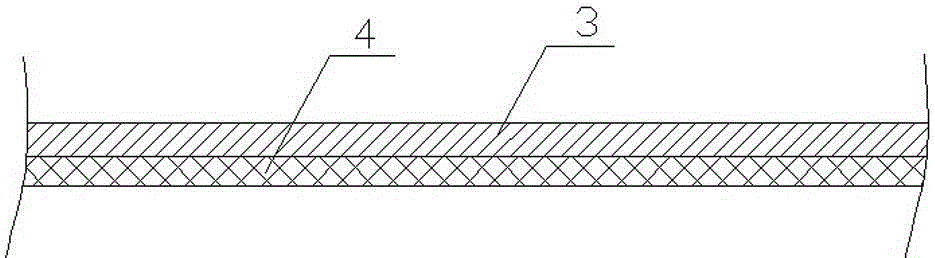

[0038] Such as figure 1 Shown is a honeycomb air filter yarn for doors and windows, the air filter yarn includes two layers of filter surfaces 1, and the connection between the two layers of filter surfaces has a number of hexagonal honeycomb connecting channels 2, and the honeycomb connecting channels are arranged in a line , the filter surface is sawtooth-shaped, and the sawtooth is a triangular tooth. The filter surface 1 is composed of an outer layer of plane skeleton material layer 3 and an inner layer of high-efficiency and low-resistance air filter material layer 4. See the attached figure 2 . The high-efficiency and low-resistance air filter material layer is purchased from 3M Company, the model is BMF-Merv12, and the thickness of the high-efficiency and low-resistance air filter material layer is 0.3mm. The thickness of the plane skeleton material layer is 0.2mm.

[0039] The planar skeleton material layer is made by mixing the following raw material components in te...

Embodiment 2

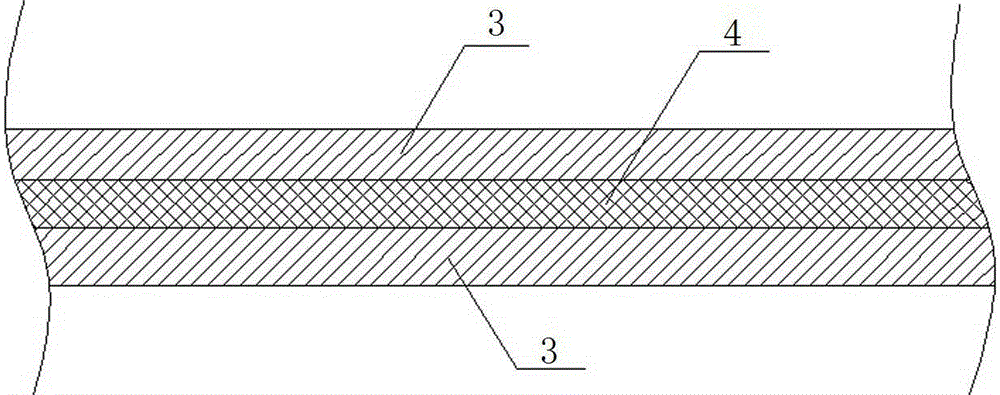

[0051] Such as figure 1 Shown is a honeycomb air filter yarn for doors and windows, the air filter yarn includes two layers of filter surfaces 1, the connection between the two layers of filter surfaces has a number of regular hexagonal honeycomb connection channels 2, and the honeycomb connection channels are arranged in a line , the filter surface is sawtooth-shaped, and the sawtooth is a triangular tooth. The filter surface 1 is composed of three layers of the outer plane skeleton material layer 3, the middle high-efficiency low-resistance air filter material layer 4 and the inner plane skeleton material layer 3. into, see attached image 3 . The high-efficiency and low-resistance air filter material layer is purchased from 3M Company, the model is BMF-Merv14, and the thickness of the high-efficiency and low-resistance air filter material layer is 0.1mm. The thickness of the plane skeleton material layer is 0.4mm.

[0052] The planar skeleton material layer is made by mi...

Embodiment 3

[0064] Such as figure 1 Shown is a honeycomb air filter yarn for doors and windows, the air filter yarn includes two layers of filter surfaces 1, the connection between the two layers of filter surfaces has a number of regular hexagonal honeycomb connection channels 2, and the honeycomb connection channels are arranged in a line , the filter surface is sawtooth-shaped, and the sawtooth is a triangular tooth. The filter surface 1 is composed of three layers of the outer plane skeleton material layer 3, the middle high-efficiency low-resistance air filter material layer 4 and the inner plane skeleton material layer 3. become. The high-efficiency and low-resistance air filter material layer is purchased from 3M Company, the model is BMF-Merv14, and the thickness of the high-efficiency and low-resistance air filter material layer is 0.2 mm. The thickness of the plane skeleton material layer is 0.3mm.

[0065] The planar skeleton material layer is made by mixing the following raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com