Multi-barrel swing impact washing device

A washing device and washing bucket technology, applied in the field of washing, can solve the problems of small water consumption, clothes cannot be washed separately, and high utilization rate of cleaning agents, so as to achieve the effect of small water consumption, improve safety factor and service life, and prevent disease infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

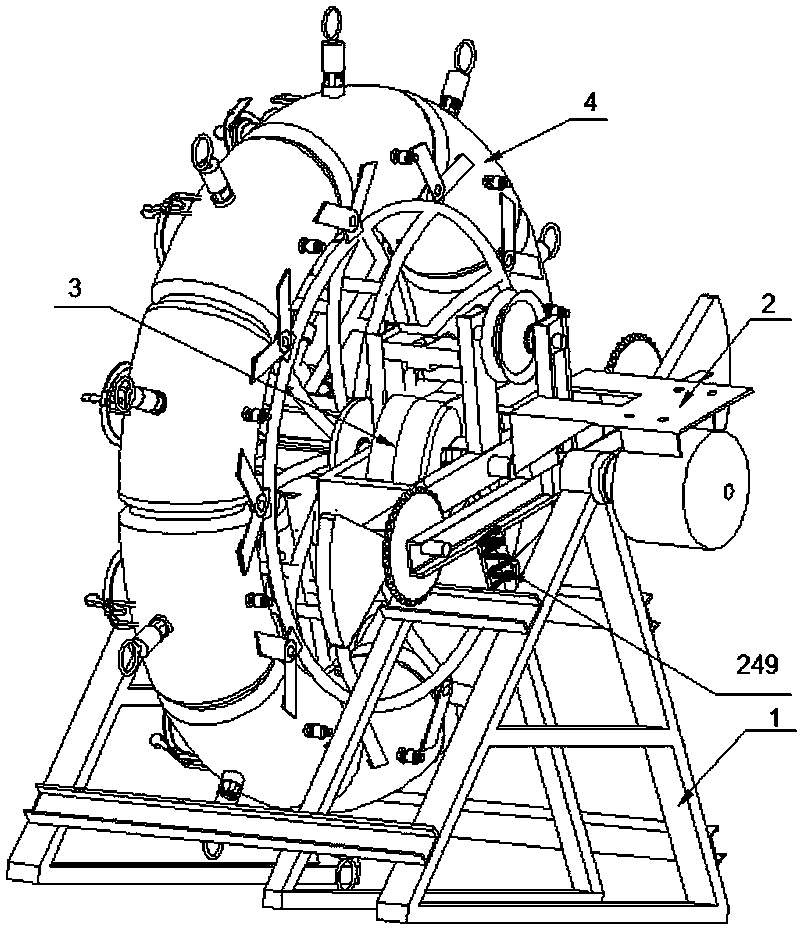

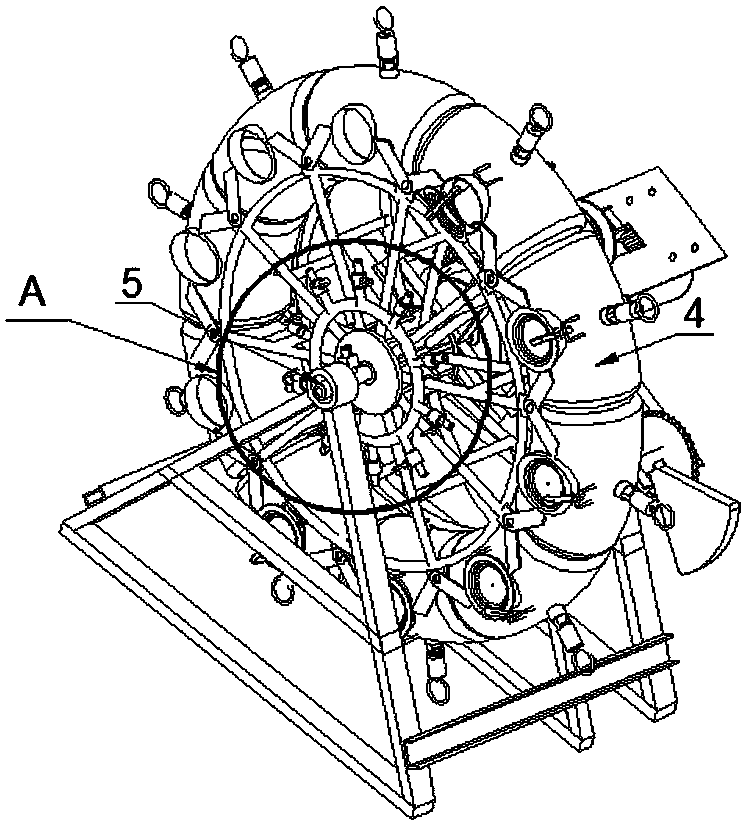

[0071] like Figure 1 to Figure 24 , Figure 27 to Figure 34 , The multi-barrel swinging impact washing device is mainly composed of a large frame 1, a power device 2, a conversion mechanism 3, a combined washing device 4 and a support shaft 5.

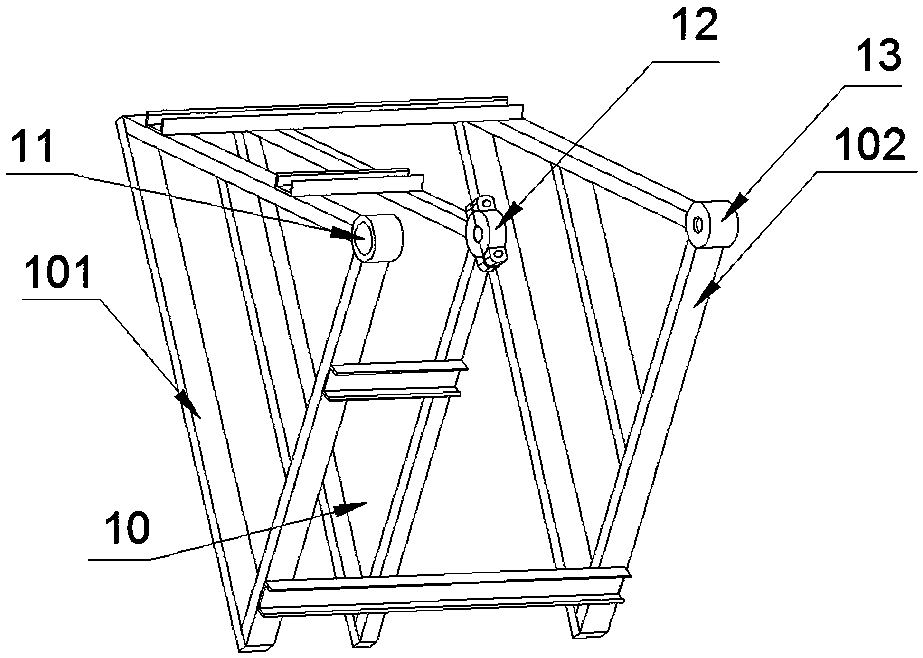

[0072]Among them, the large frame 1 is composed of the frame body 10 and the first bearing seat 11, the second bearing seat 12, and the third bearing seat 13 on the upper part of the frame body 10. For the functional frame, the three bearing seats are arranged concentrically. On the same axis, due to assembly reasons, the bearing seats can be split bearing seats; the first bearing seat 11 and the second bearing seat 12 are assembled with power Device 2, the power device 2 provides power for the combined washing device 4, so that the combined washing device 4 swings or rotates. The power device 2 is composed of a power motor 21, a power motor support frame 22, a power shaft 23 and a swing drive system 24. The power motor 21 is a comm...

Embodiment 2

[0116] like Figure 1 to Figure 22 , Figure 25 to Figure 34 , The multi-barrel swinging impact washing device is mainly composed of a large frame 1, a power device 2, a conversion mechanism 3, a combined washing device 4, and a support shaft 5.

[0117] The horizontal water discharge valve 44 includes a water discharge valve connecting screw 441, a horizontal water discharge valve body 442, a horizontal water discharge valve ball head 443, a horizontal compression spring 444, a spring support frame 445, a spring adjustment hole 446, and a spring fixing bolt 447. , the spring fixed shaft 448, the upper part of the drain valve connecting screw 441 is connected to the horizontal drain valve body 442, and the bottom is connected to the washing tub 41, the horizontal drain valve body 442 is equipped with a horizontal drain valve ball 443, so The horizontal compression spring 444 is arranged on the spring fixing shaft 448, one end of the horizontal compression spring 444 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com