Hydraulic cylinder piston sealing device under high temperature situation

A high-temperature working condition, sealing device technology, applied in the direction of engine sealing, fluid pressure actuation device, engine components, etc., can solve the problems of stuck cylinder seal failure, expansion deformation, etc., to suppress piston expansion, prevent cylinder stuck, resist Excellent high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

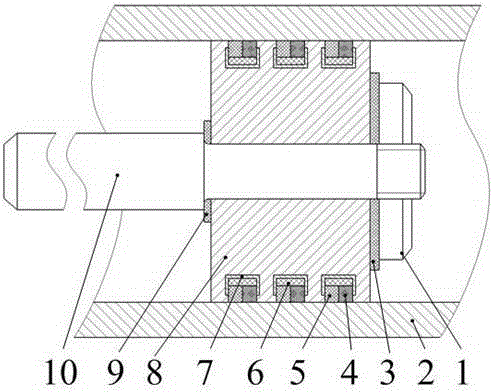

[0015] Such as figure 1 As shown, a hydraulic cylinder piston sealing device under a high temperature working condition of the present invention mainly includes a piston 8, a constant range steel plate 7, a sealing ring A4, a sealing ring B5, an elastic ring 6 and a piston rod 10, and the piston rod 10 ends The end is provided with a shaft shoulder and an external thread, and the elastic retaining ring 9, the piston 8, the elastic washer 3 and the lock nut 1, the constant fan steel sheet 7, the elastic ring 6, the sealing ring A4 and the sealing ring are installed in sequence from the inside to the outside B5 is installed in the groove of piston 8 successively.

[0016] The piston 8 is made of aluminum alloy, which enables the piston 8 to dissipate heat in time under high-temperature operation due to the advantages of good thermal conductivity of the aluminum alloy. There are 3 grooves on the outer surface of the piston 8 .

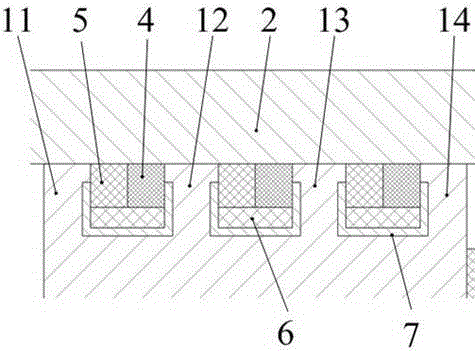

[0017] combine figure 2 As shown, the constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com