Multi-freedom-degree low-frequency large-load all-metal passive vibration isolator

A vibration isolator and ultra-low frequency technology, applied in the direction of non-rotational vibration suppression, etc., to achieve the effect of strong adjustment ability, compact structure, and reduced force transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention will be described in more detail hereinafter with reference to the accompanying drawings showing embodiments of the invention. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. In these drawings, the size and relative sizes of layers and regions may be exaggerated for clarity.

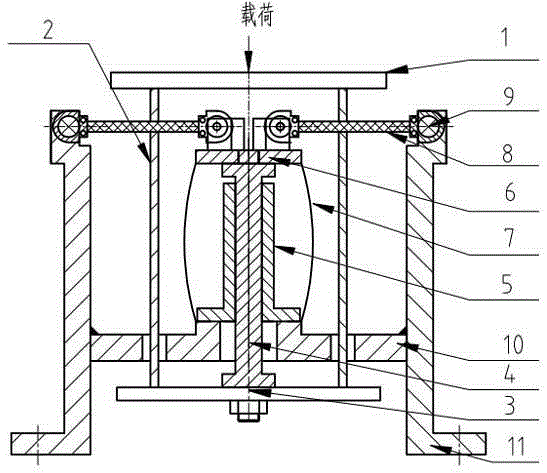

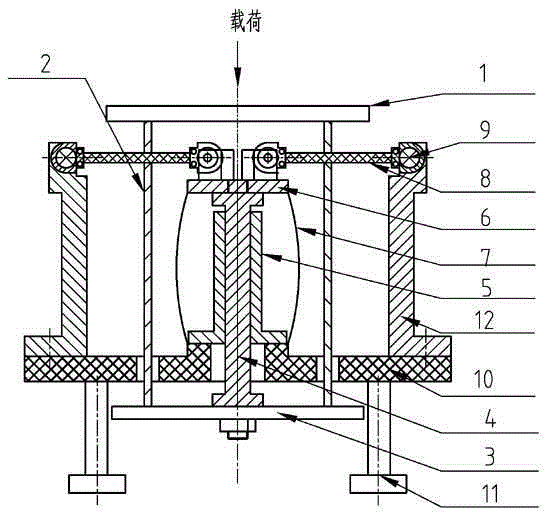

[0037] refer to Figure 1-2 , the present invention provides a multi-degree-of-freedom ultra-low-frequency large-load all-metal passive vibration isolator, which has high static stiffness and low dynamic stiffness nonlinearity, and overcomes the contradiction between deformation and natural frequency of traditional vibration isolators. Based on the Euler strut and the negative stiffness mechanism, the invention constructs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com