Air suspension based on quasi-zero stiffness principle and structural design and optimization method thereof

An air suspension, quasi-zero stiffness technology, applied in design optimization/simulation, suspension, elastic suspension, etc., can solve the problem that air springs and rack and pinion mechanisms occupy large space, do not consider instability, and adverse performance Stability and other issues, to achieve the effect of expanding the vibration isolation range, miniaturizing the volume of the mechanism, and compacting the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

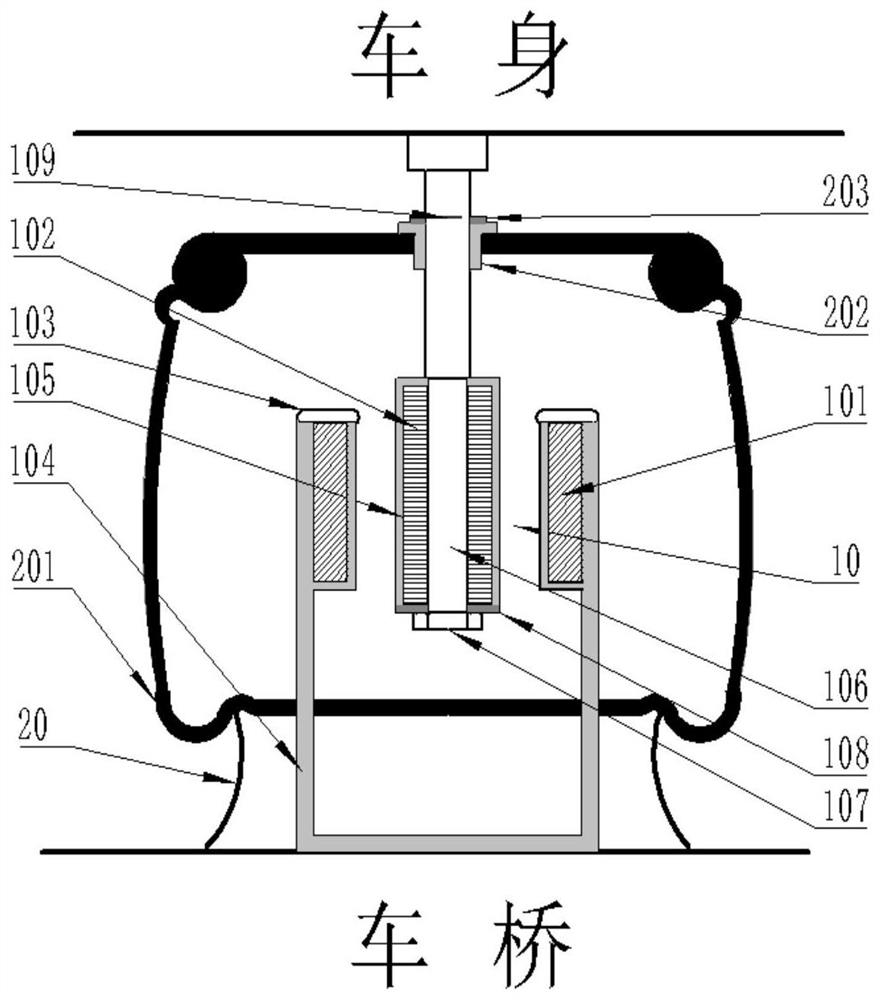

[0046] like figure 1 As shown, an air suspension designed based on the principle of quasi-zero stiffness includes a magnetic negative stiffness mechanism 10 and an air spring mechanism 20 .

[0047] The magnetic negative stiffness mechanism 10 includes a energized coil 101 , an annular permanent magnet 102 , an anti-collision rubber pad 103 , a cylinder 104 , a sleeve 105 , a piston rod 106 , a lock nut 107 , a protection washer 108 , and a marking line 109 . The air spring mechanism 20 includes a membrane air spring 201 , a sliding bearing 202 and a sealing ring 203 .

[0048] The bottom of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com