Starting bed material setting method and device for circulating fluidized bed

A circulating fluidized bed and bed material technology, applied in the field of circulating fluidized bed, can solve problems such as long start-up time, low input rate of automatic control, difficulty in self-starting of circulating fluidized bed boilers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

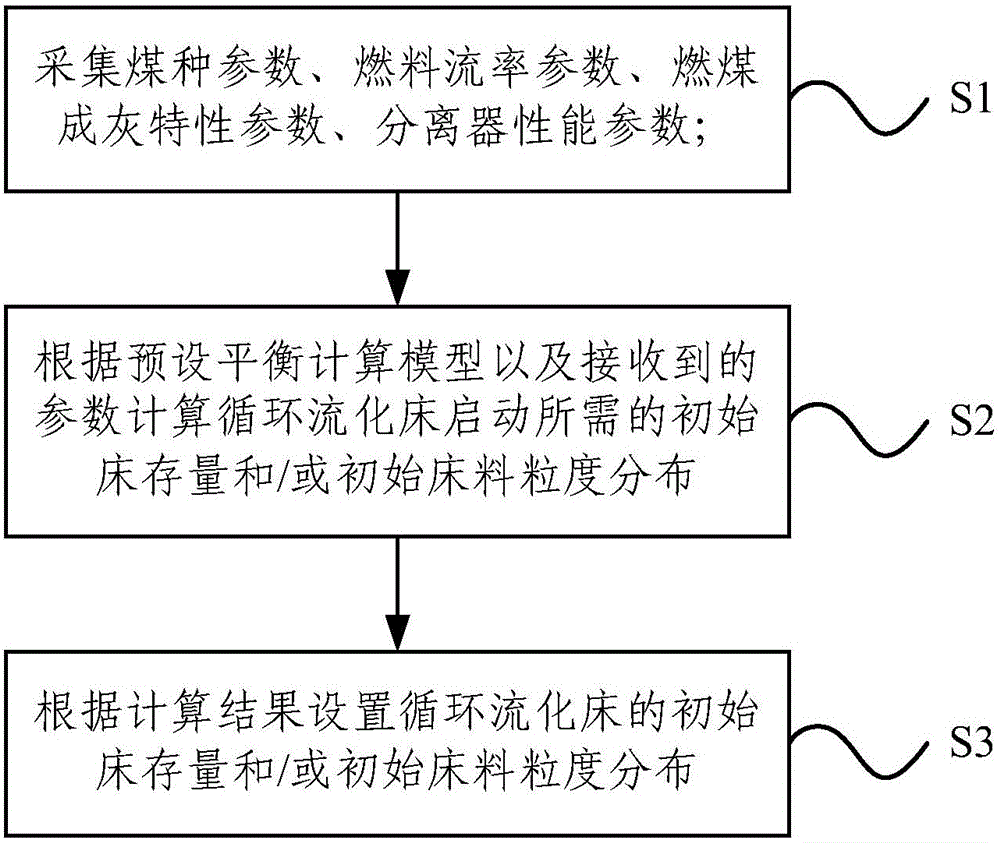

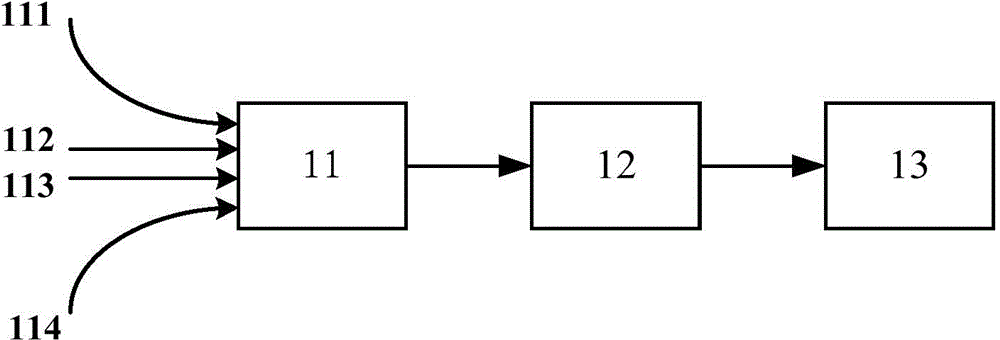

[0029] like figure 1 As shown, the starting bed material setting method of a circulating fluidized bed according to an embodiment of the present invention includes: S1: receiving coal type parameters, fuel flow rate parameters, coal ash formation characteristic parameters, and separator performance parameters; S2: according to the preset Set the balance calculation model and the received parameters to calculate the initial bed inventory and / or initial bed material particle size distribution required for the start-up of the circulating fluidized bed; S3: set the initial bed inventory of the circulating fluidized bed according to the calculation results and / or initial bed material particle size distribution.

[0030] Preferably, the balance calculation model includes:

[0031] M dX i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com