Straight-through type single-tube solar absorber with semielliptical glass cover

A technology of solar energy absorption and glass cover, which is applied to solar collectors, solar collectors using working fluids, solar thermal energy, etc., can solve the problems of light reduction, light loss, and reduced optical efficiency to reduce heat loss , Inhibit convective heat transfer, uniform heat flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

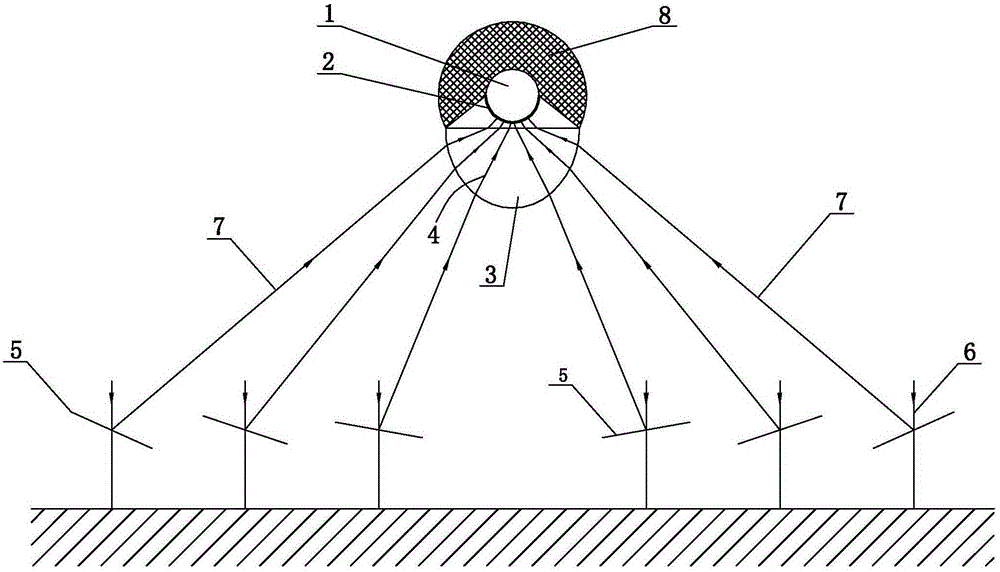

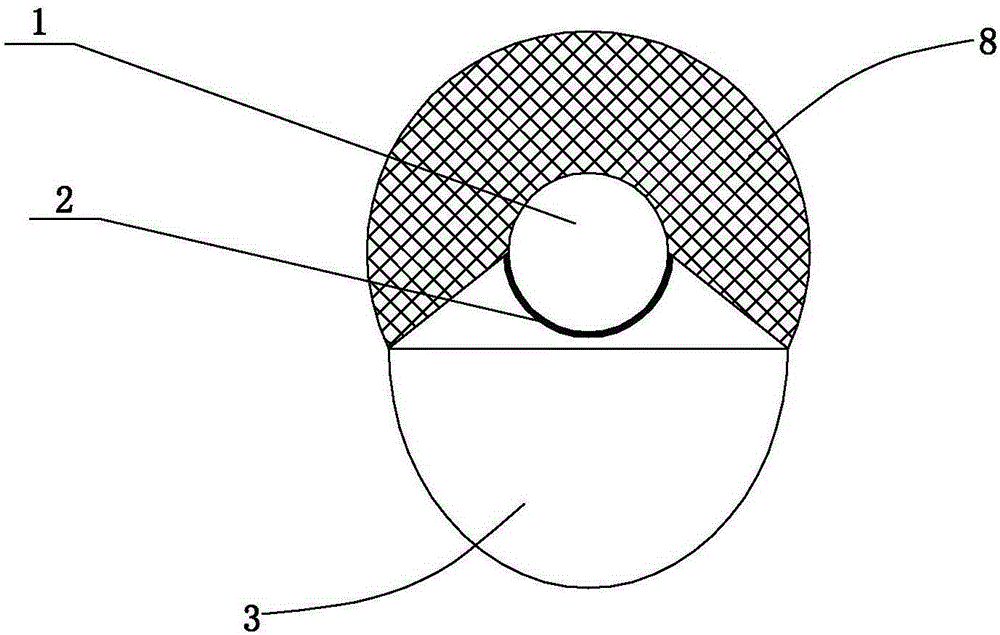

[0020] Such as figure 1 , figure 2 The shown straight-through single-tube solar absorber with a semi-elliptical glass cover includes an absorber tube 1 and a glass cover 3 located below the absorber tube 1. The absorber tube 1 is a straight-through metal round tube made of steel. Stainless steel can also be used. The outer diameter of the absorption pipe 1 is 204mm, and the inner diameter of the pipe is 200mm. The half circumference is wrapped with insulation layer, and the lower half circumference of absorption pipe 1 is not wrapped with insulation layer. Layer 8 has an inner arc surface and an outer arc surface, the inner arc surface is close to the upper half circumference of the absorption tube 1, the central angle corresponding to the inner arc surface is 180°, and the center angle corresponding to the outer arc surface is 227.4°.

[0021] The insulation layer 8 is made of slag wool, and glass wool or microporous calcium silicate can also be used. The broken fan-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com