Rotary arm type ash sample transfer mechanism for on-line detection of fly ash carbon content by weight loss method

A technology of fly ash carbon content and transfer mechanism, which is applied in the direction of removing certain components and weighing, etc., can solve the problems of detection interruption, increase the number of detections, manual replenishment, etc., so as to avoid detection interruption, improve accuracy, and improve Detecting the effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

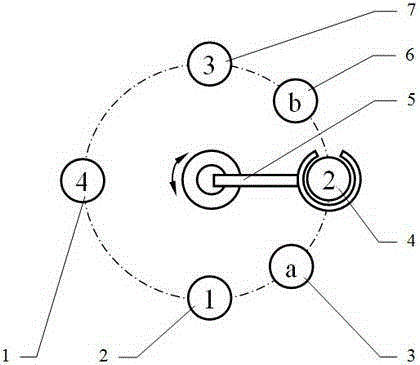

[0016] 1. The gray sample conveying process is as follows (refer to the attached picture):

[0017] a. The initial state before operation is: three crucibles are placed on the sampling station 2, the temporary bracket 3 and the spare bracket 6 respectively;

[0018] b. The first operation: the swivel arm 5 transports the crucible with the ash sample obtained at the sampling station 2 to the weighing station 4 for weighing, and then sends the weighed ash sample to the burning station 1 for burning; the swivel arm 5 Then, the crucible on the temporary bracket 3 is sent to the sampling station 2 and the weighing station 4 in turn to complete the sampling and weighing process, and then sent to the sampling station 2 for temporary storage, in a preparation state before burning;

[0019] c. Continuous operation stage: the rotating arm 5 takes out the ash sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com