A cob light source light output structure and its application

A light source and grid technology, which is applied in the field of COB light source light structure, can solve the problems of low luminous efficiency and uniformity of chips, low luminous efficiency and uniformity of light sources, and increased relative quantity of reflected light, etc., to achieve good color temperature consistency of light sources, Increased luminous flux and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

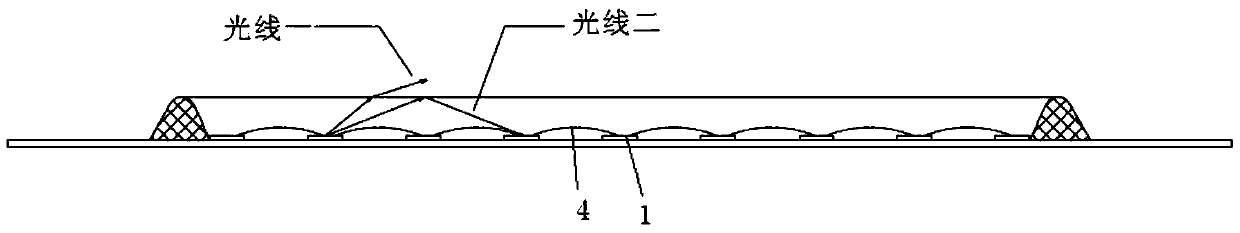

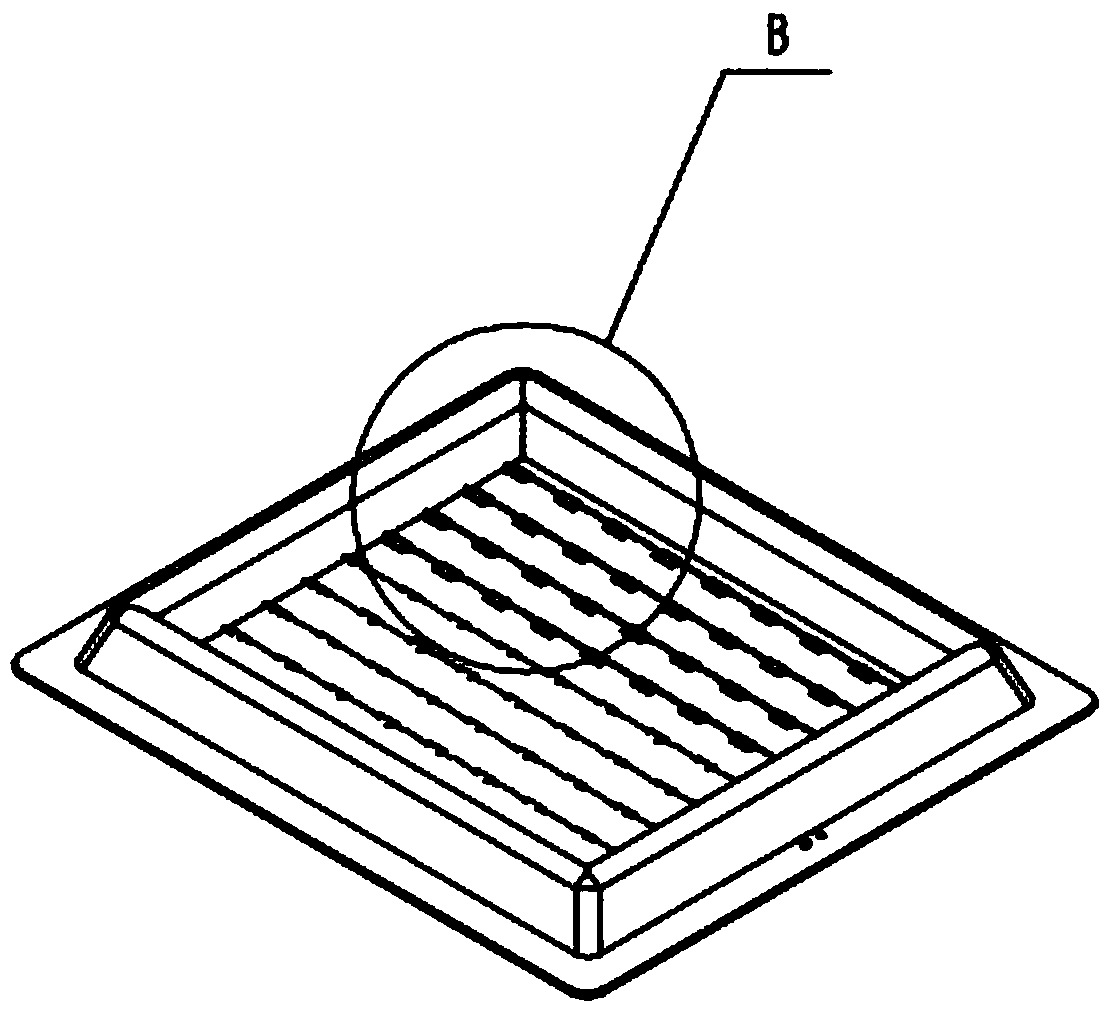

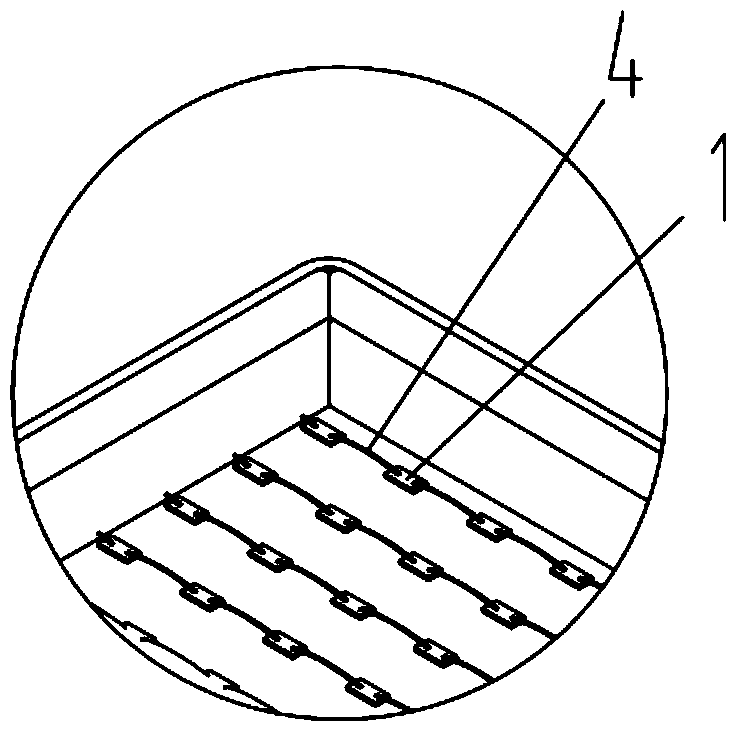

[0022] like Figure 1~Figure 7 As shown in the figure, a light-emitting structure of a COB light source is characterized in that it includes: a grid 2 separating adjacent wafers 1, the grid 2 includes grid bars 3 with a triangular cross-section in a crisscross pattern. The bottom end of the grid bars 3 is provided with a number of notches 5 for passing through the bonding wires 4 .

[0023] The notch 5 includes a V-shaped notch.

[0024] The material of the grille 2 includes white PC or white silica gel.

[0025] The height of the grid 2 is the same as the height of the filled silica gel.

[0026] The grille 2 is arranged on the heat dissipation substrate, and the cup-shaped cavities enclosed by the grille 2 and the heat dissipation substrate are filled with the filled silica gel; the bottom surface area of the cup-shaped cavity is smaller than the top surface. a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com