Method and device for improving color temperature consistency of white light LED (Light Emitting Diode) lighting device

A technology of LED lighting and consistency, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of difficulty in adjusting the thickness of the phosphor powder of the LED chip, high consistency, and the inability to meet the luminous color temperature of the array LED devices in large quantities, etc. Achieve the effect of improving color temperature (or wavelength) consistency and improving color temperature consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

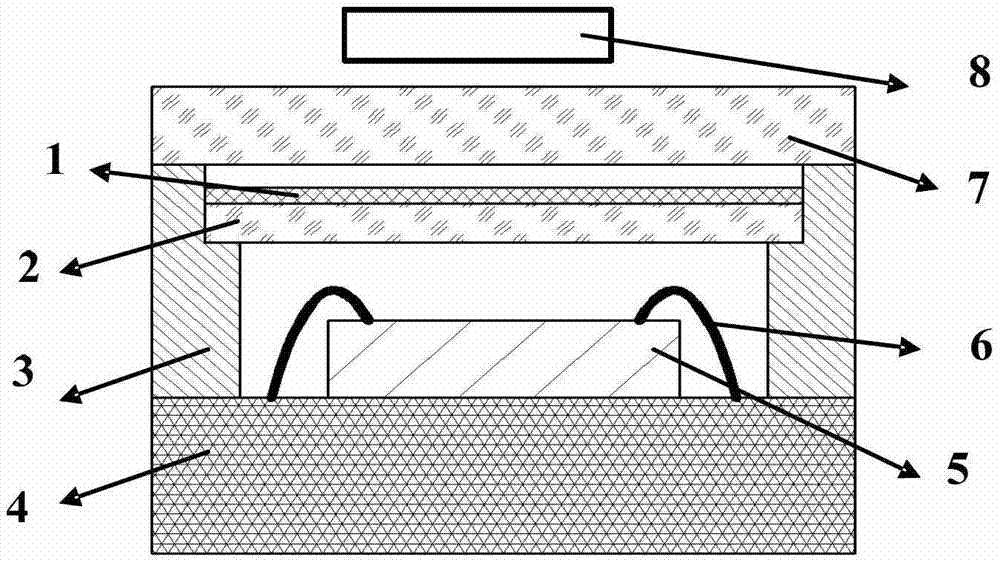

[0030] Example 1: Embodiment of a phosphor coating method for improving the color temperature consistency of a single-chip LED lighting device

[0031] like figure 1 As shown, it is assumed that the manufacturing target of the LED lighting device is: the color temperature range is K 0 ±Δk. For example: positive white LED: 6250±250k. (White LED lighting devices manufactured by traditional methods have a color temperature range of 3200-7000k, and rely on subsequent sorting to classify devices of various color temperatures, in order to obtain devices with a specific range of color temperature, such as: 6250±250k However, this method has low yield and high cost. By using the method of the present invention, LED lighting devices with a color temperature of 6250±250k can be directly obtained without sorting.)

[0032] For the LED chip fixed on the substrate, cover the light-transmitting mirror and spray silica gel on the light-transmitting mirror. The thickness is 500 microns by ...

Embodiment 2

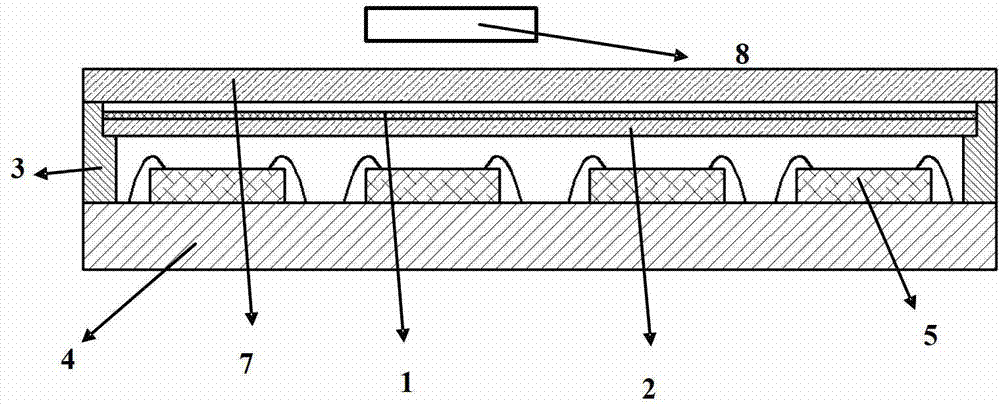

[0038] Example 2: Embodiment of phosphor coating method for improving color temperature consistency of array chip LED lighting devices

[0039] Assume that the manufacturing target of the LED lighting device is: the color temperature range of the light wave is K 0 ±Δk. For example: positive white LED: 6250±250k.

[0040] like figure 2 As shown in the figure, for the LED array chip fixed on the substrate, first, cover the light-transmitting mirror and evenly spray silica gel on the light-transmitting mirror with a thickness of 500 microns, and then uniformly spray the light-transmitting mirror with phosphor powder with a thickness of 50 microns.

[0041] ①Detection: After spraying, power on the LED chips fixed on the substrate; use the optical fiber color temperature or the movable probe of the wavelength detection equipment to detect the light wave color temperature of each LED chip through the light-transmitting mirror and phosphor powder, and Record the test results in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com