Thermocouple wire stripping tool

A stripping tool and thermocouple technology, applied in the direction of dismantling/armored cable equipment, etc., can solve the problems of thin alkali-free glass wire, easy to cause allergies, and high labor intensity, and achieve simple operation, improve production efficiency, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

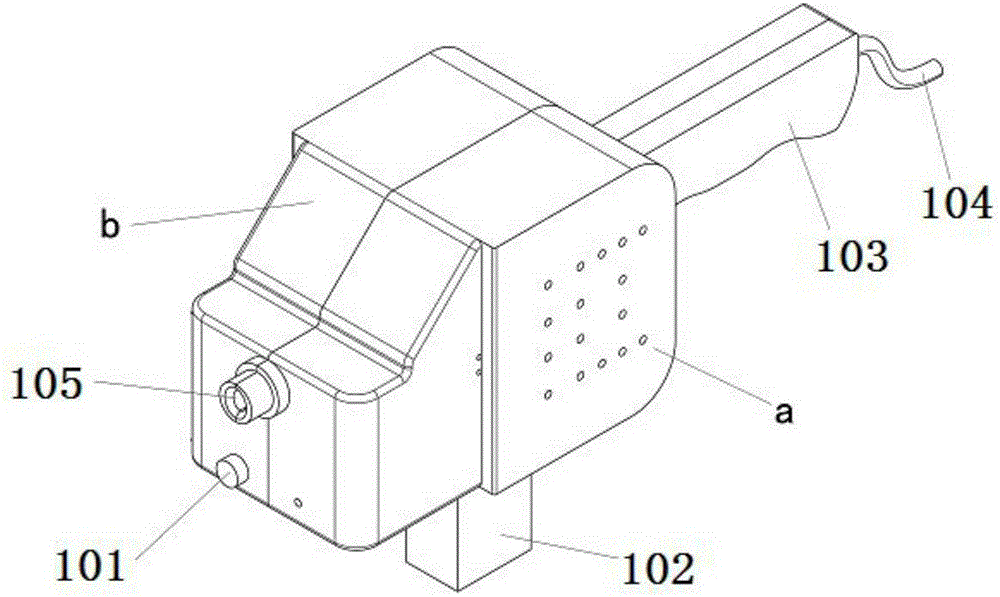

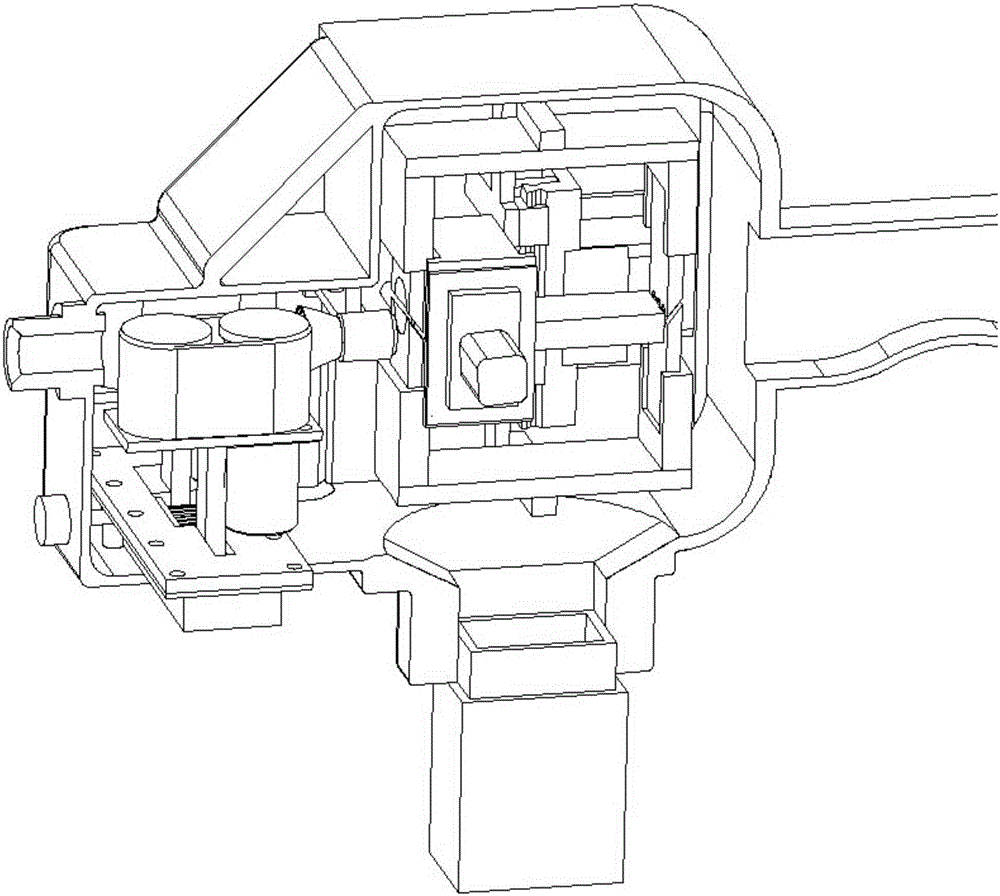

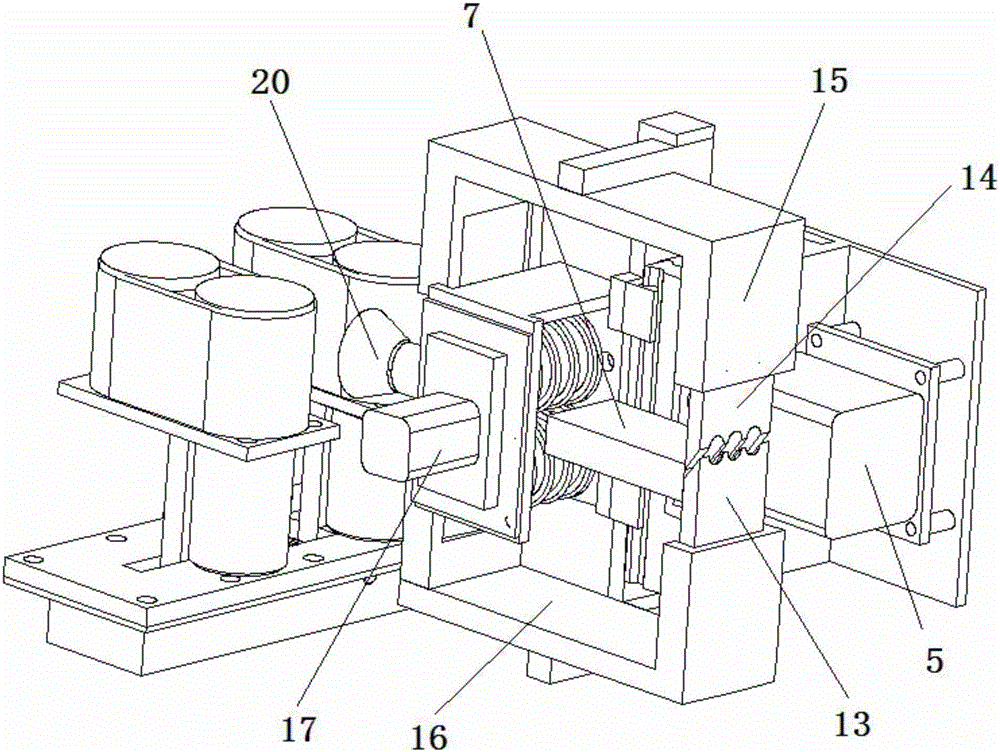

[0032] A thermocouple wire stripping tool, including a wire feeding mechanism, a thin wire separating mechanism and a stripping mechanism,

[0033] Described peeling mechanism comprises the first frame 1, the first slide block 11, the first rack 12, the following cutter support 16, the second slide block 4, the second rack 8, the upper cutter support 15, the first gear 10 , the first motor 5, the branching conduit 7, the front cutter group and the rear cutter group, the front cutter group includes the front lower cutter 19 and the front upper cutter 18, and the rear cutter group includes the rear lower cutter 13 and rear upper cutter 14,

[0034] The first frame 1 is provided with a first slide rail 2 and a second slide rail 6, the first slide block 11 cooperates with the first slide rail 2, and the first rack 12 and the lower cutter bracket 16 are fixed on the first slide rail. On the block 11, the front lower cutter 19 and the rear lower cutter 13 are respectively installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com