Bi-directional overrunning clutch with improved indexing mechanism

一种超速离合器、离合器壳体的技术,应用在离合器领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

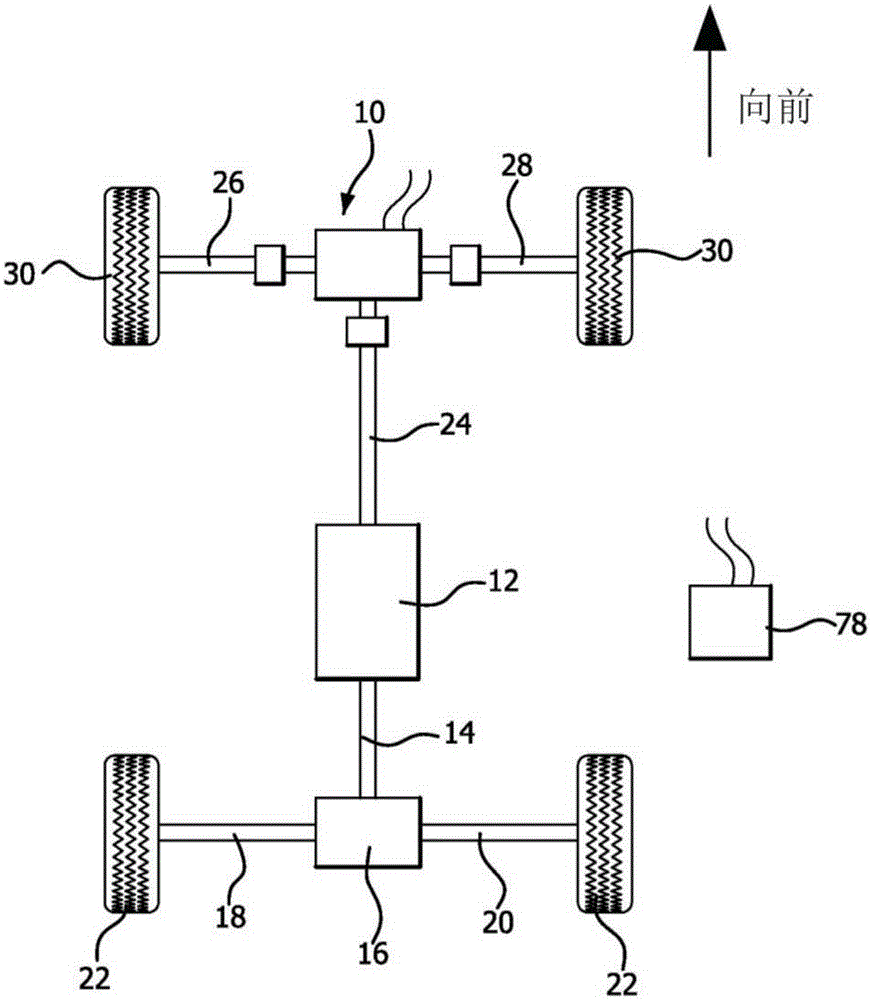

[0041] Referring now to the drawings, wherein like reference numerals illustrate corresponding or like elements throughout the several views. figure 1 is a schematic diagram of one embodiment of a drive system incorporating a two-way overrunning clutch assembly 10 according to one embodiment of the present invention. The drive system includes a transmission 12 , a main drive shaft 14 , a main differential 16 , and first and second drive shafts 18 , 12 driving main wheels 22 .

[0042] The drive system also includes a secondary drive shaft 24 rotatably connected to the two-way overrunning clutch assembly 10 by any conventional means known to those skilled in the art, such as a splined connection. The two-way overrunning clutch assembly 10 in turn rotatably drives two secondary driven shafts 26 , 28 which are attached to wheels 30 .

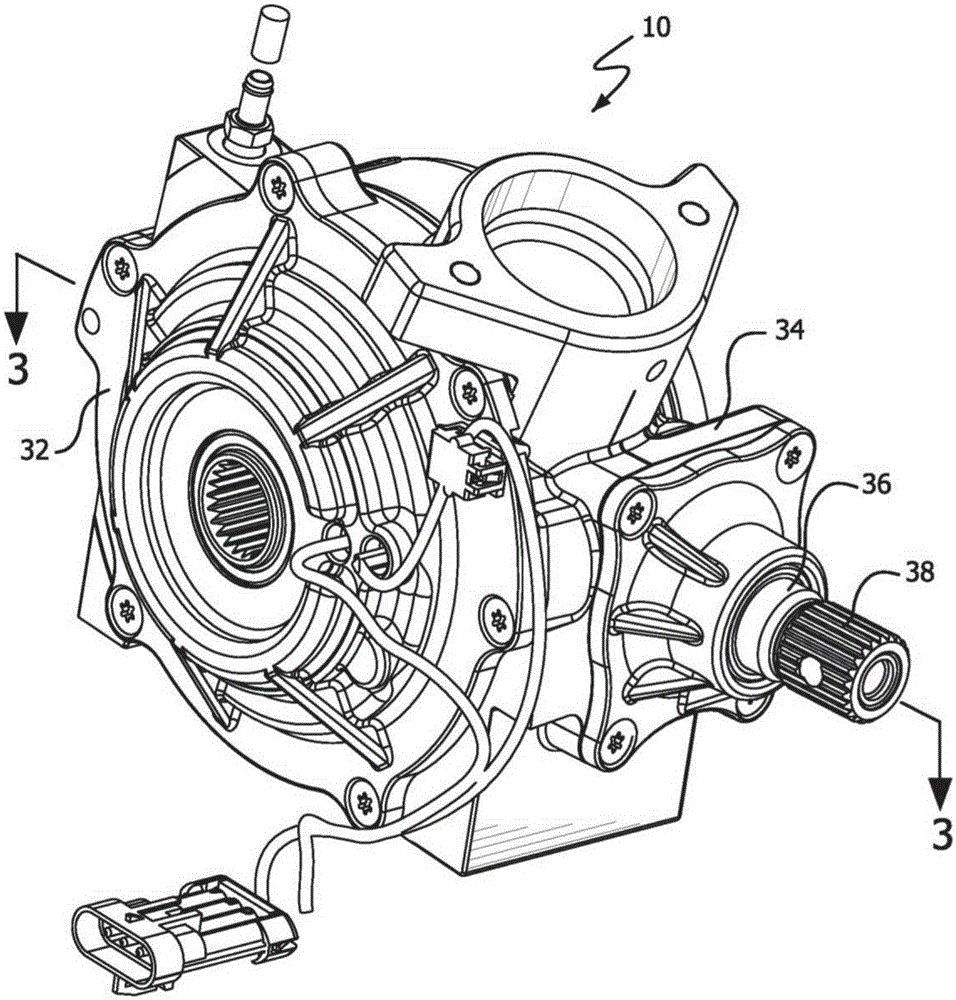

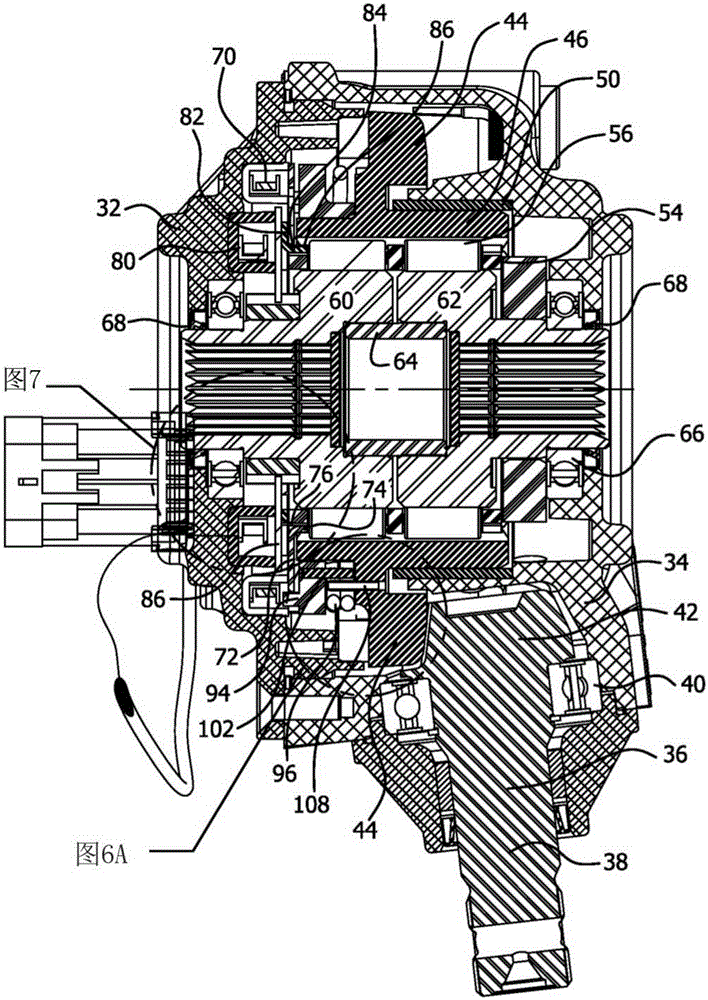

[0043] The details of the two-way overrunning clutch assembly 10 will be compared to Figures 2 to 12B to describe. figure 2 is a perspective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com