Anti-blocking fertilizer distributor

A fertilizer applicator and anti-clogging technology, which is applied to fertilization devices, fertilizer distributors, applications, etc., can solve problems such as increased labor load, uneven feeding, and regardless of soil, and achieve the effect of improving operating efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

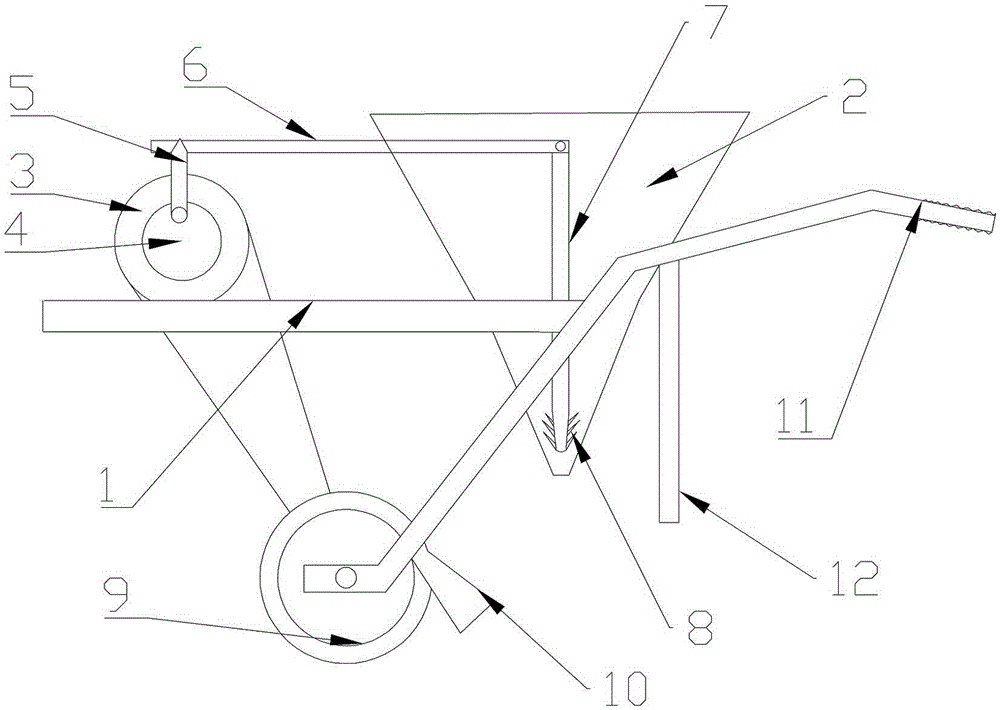

[0014] Frame 1, hopper 2, driving wheel 3, cam 4, ejector rod 5, cross bar 6, stirring rod 7, inverted tooth 8, wheel 9, baffle plate 10, handle 11, bicycle foot 12.

[0015] The embodiment is basically as attached figure 1 Shown: including frame 1, two wheels 9 are installed on the bottom of frame 1, gasoline engine is installed on the left side of frame 1, coaxial drive wheel 3 and cam 4 are connected on the gasoline engine, drive wheel 3 and wheel 9 Connected by a belt; the right side of the frame 1 is a funnel-shaped hopper 2, the outlet of the hopper 2 is located at the bottom of the hopper 2, and the right side of the hopper 2 is two handles 11, and the grip of the handle 11 is provided with anti-slip protrusions ; The frame 1 is also equipped with two telescopic car feet 12, which can play a role of balance support when the fertilizer applicator stops. A vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com