Method for preparing zinc chelated peptide by utilizing shrimp meat offal

A technology of leftovers and chelating peptides, which is applied in protein food processing, animal protein processing, food science, etc., and can solve the problems of high cost of protein and astaxanthin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] 1) Preparation of protein hydrolyzate from shrimp processing waste: Grind the leftovers (shrimp head and shell) of frozen shrimp processing with a tissue grinder, add phosphate buffer (0.2mol / L, pH7.0) according to the ratio of solid to liquid 1g: 5mL, and put them under ultrasonic power at 47°C. Sonicate at 500W for 90min, then add neutral protease (enzyme activity ≥ 5.0×10 4 U / g), after incubating at 47°C for 2h, the temperature was raised to 95°C and maintained for 10min; the temperature of the solution was lowered to 37°C, the pH was adjusted to 7.8, and trypsin (enzyme activity ≥ 2.5×10 4 U / g) after 3 hours of heat preservation, the temperature rose to 95 ° C and kept for 10 minutes, at 10000 g Centrifuge for 15 minutes to obtain the supernatant, that is, the proteolyzate of shrimp processing leftovers.

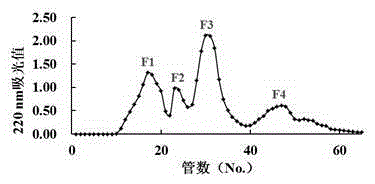

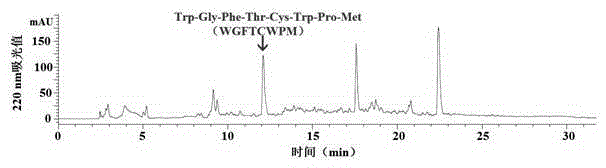

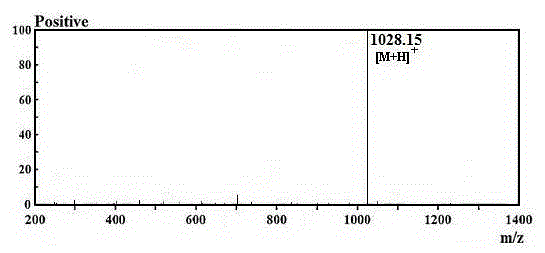

[0022] 2) Preparation of zinc chelating peptide from shrimp processing waste: The prepared enzymatic hydrolyzate is subjected to ultrafiltration treatment wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com