Dynamic-pressurizing-locked bone screw and use method thereof

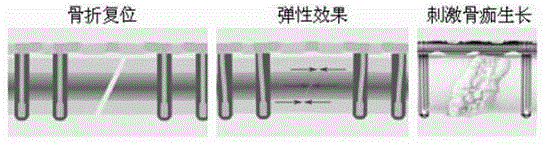

A bone screw, dynamic technology, applied in the field of dynamic compression locking bone screw, can solve the problems of internal fixation fatigue fixation, internal fixation failure, failure, etc., to avoid bone nonunion, fast postoperative recovery, and promote callus the formation of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

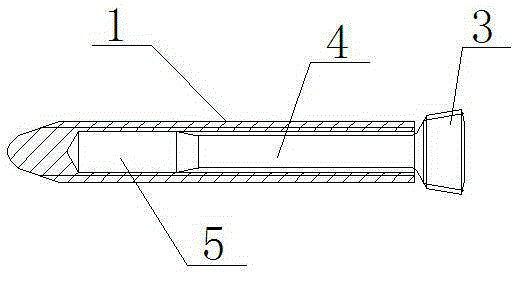

[0019] Embodiment 1: A dynamic compression locking bone screw as shown in the accompanying drawings, which includes a screw sleeve 1 and a screw core, the screw core includes a top cap 3, a polished rod 4, and a nail head 5, and the screw sleeve 1 is sleeved on the polished rod 4 , the periphery of the nail head 5, a gap is arranged between the screw sleeve 1 and the polished rod 4, and the screw sleeve 1 is connected with the nail head 5.

[0020] The screw core and the screw sleeve 1 are fixed together by interference fit to form a dynamic elastic fretting structure in which the screw sleeve can move radially along the screw core.

[0021] Further, the screw mandrel end is provided with a polished rod 4, the nail head 5 is an interference assembly structure, the screw sleeve 1 is a closed inner hollow structure with a light hole inside the closed end, and the screw core and the screw sleeve 1 pass through the The form of positive fit is fixed together.

[0022] The end of t...

Embodiment 2

[0028] Embodiment 2: A dynamic compression locking bone screw, which includes a screw sleeve 1 and a screw core, the screw core includes a top cap 3, a polished rod 4, and a nail head 5, and the screw sleeve 1 is set on the periphery of the polished rod 4 and the nail head 5, There is a gap between the screw sleeve 1 and the polished rod 4 , and the screw sleeve 1 is connected with the nail head 5 .

[0029] The screw core and screw 1 set are fixed together through internal and external thread connections, forming a dynamic elastic micro-movement structure in which the screw set 1 can move radially along the screw core.

[0030] Further, the screw mandrel end is provided with a polished rod 4, the nail head 5 is an external thread structure, the screw sleeve 1 is a closed inner hollow structure at one end, and the closed end is internally threaded, and the screw core and the screw sleeve 1 are fixed in the form of an internal and external thread connection together. The metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com