Separation method of low-grade magnetic minerals

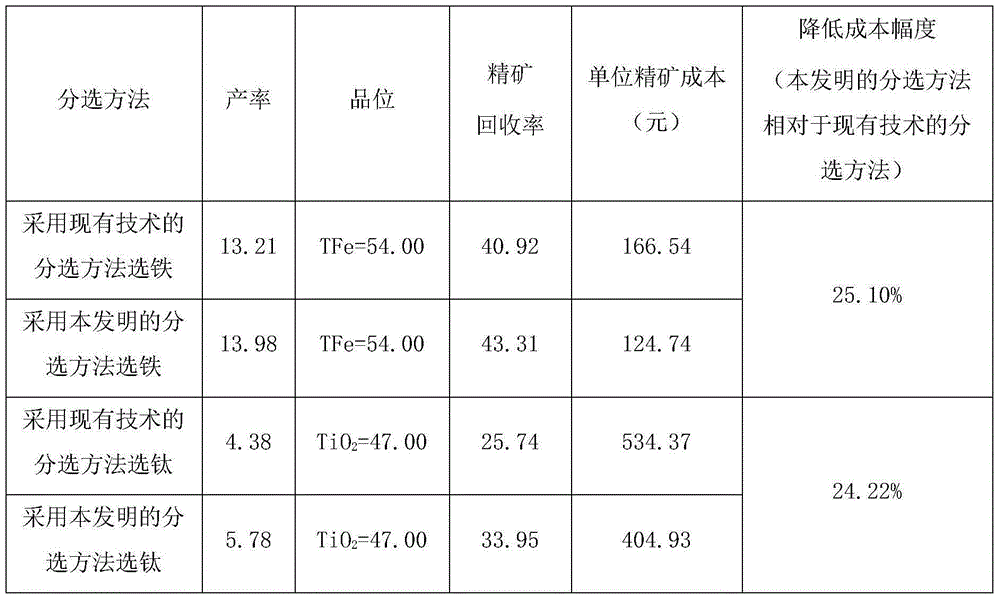

A low-grade, sorting technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of low sorting rate, high sorting cost, difficult economic benefits, etc., to improve the sorting grade , reduce the amount of sorting, reduce the effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

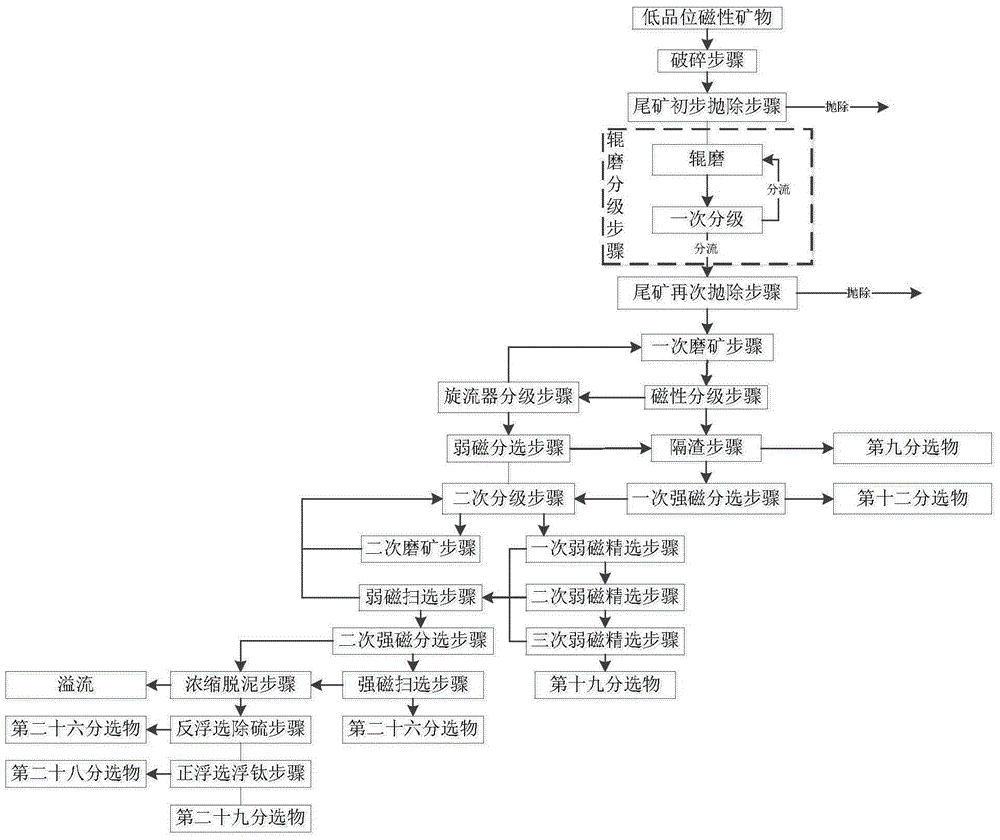

[0023] The invention provides a sorting method for low-grade magnetic minerals, such as figure 1 As shown, the sorting method includes the following steps:

[0024] First, the crushing step: using a crusher (such as a gyratory crusher or a cone crusher) to crush the low-grade magnetic minerals to obtain the crushed low-grade magnetic minerals;

[0025] Second, the preliminary tailing removal step: use a dry bulk magnetic separator to perform a dry tailing process on the crushed low-grade magnetic minerals, so as to remove part of the non-magnetic minerals in the crushed low-grade magnetic minerals and / or weakly magnetic minerals are discarded as tailings;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com