Sorting device and method for waste recycling

A sorting device and waste product technology, which is applied in chemical instruments and methods, solid separation, transportation and packaging, etc., can solve the problem that the distribution center is too small, it is difficult to sustain and spread in a large area, and it consumes a lot of manpower for waste pretreatment and sorting and other issues to achieve the effect of improving efficiency, facilitating recycling and reducing the amount of sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

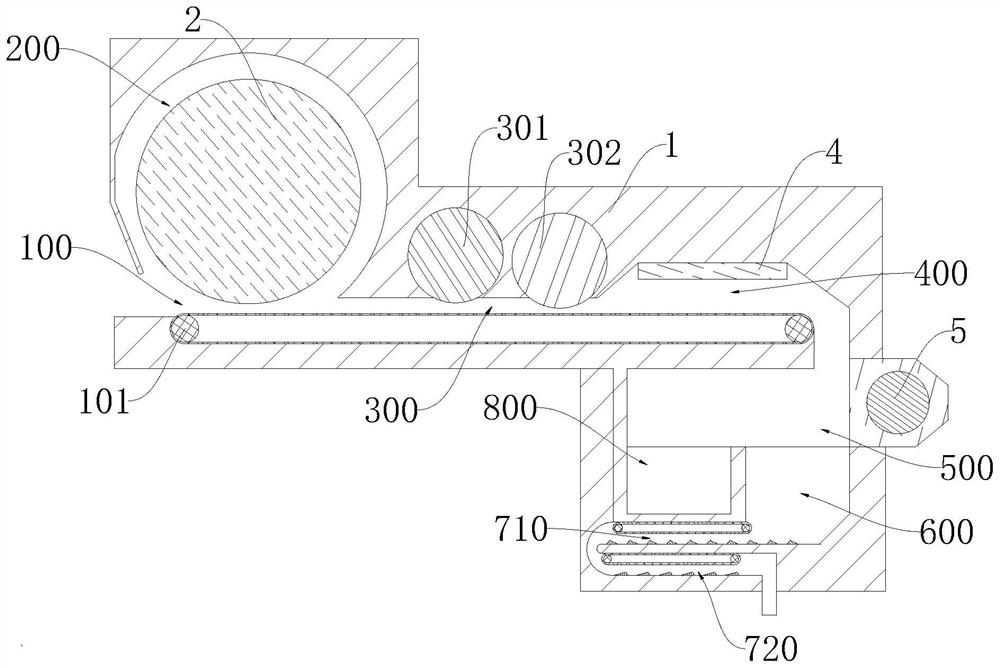

[0043] Such as figure 1 , 2 As shown, the present embodiment provides a sorting device for waste recycling, including a support frame 1, which is provided with a feeding channel 100, a compression channel 200, a cutting channel 300, a metal separation channel 400, and a sorting channel. 500 and recovery bin 600, the feed channel 100, the compression channel 200, the cutting channel 300, the metal separation channel 400, the sorting channel 500 and the recovery bin 600 are connected in sequence, the compression A pressing wheel 2 is arranged in the passage 200, and the inner diameter of the outlet of the compression passage 200 is smaller than the inner diameter of the inlet of the compression passage 200, and a cutting wheel is arranged in the cutting passage 300, and the working end of the cutting wheel Located in the cutting channel 300 , the metal separation channel 400 is provided with an electromagnet 4 , and the sorting channel 500 is provided with a fan 5 , and the fan...

Embodiment 2

[0058] Such as figure 1 , 2 As shown, this embodiment is based on Embodiment 1, and the cutting wheels include a first cutting wheel 301 and a second cutting wheel 302 .

[0059] In this embodiment, the cutting wheels include a first cutting wheel 301 and a second cutting wheel 302 , and the first cutting wheel 301 and the second cutting wheel 302 improve the efficiency of cutting waste products.

[0060] In some implementations of this embodiment, the distance between the first cutting wheel 301 and the inner wall of the cutting channel 300 is greater than the distance between the second cutting wheel 302 and the inner wall of the cutting channel 300 .

[0061] In the above embodiment, the distance between the first cutting wheel 301 and the inner wall of the cutting channel 300 is greater than the distance between the second cutting wheel 302 and the inner wall of the cutting channel 300, so that the first cutting wheel 301 performs primary Cutting, the second cutting whee...

Embodiment 3

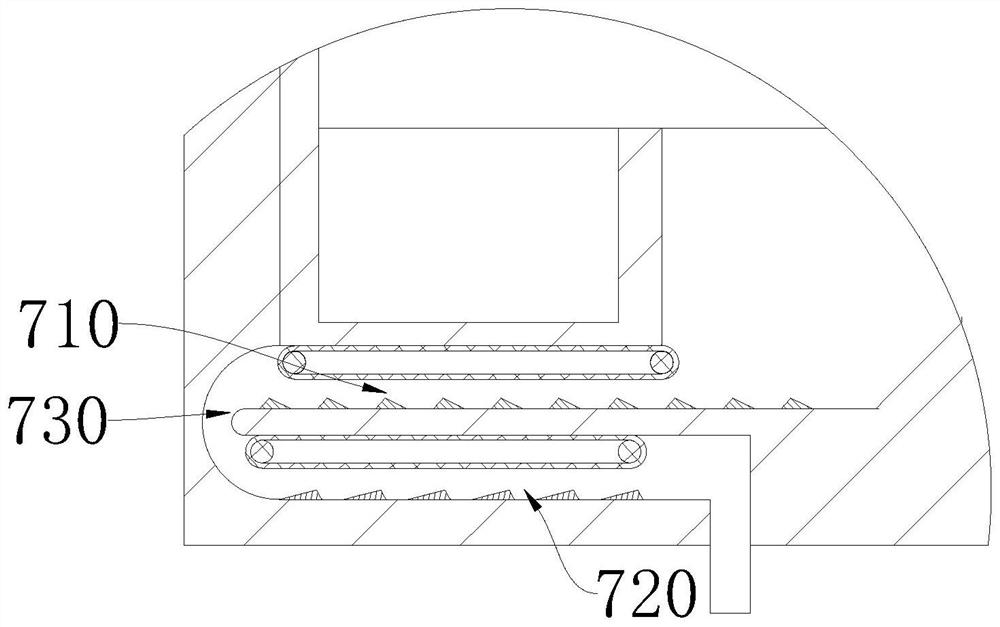

[0063] Such as figure 1 , 2 As shown, a lightweight collection bin 800 is also included, and the lightweight collection bin 800 communicates with the sorting channel 500 .

[0064] In the above embodiment, a lightweight collection bin 800 is also included, and the lightweight collection bin 800 is communicated with the sorting channel 500. The lightweight collection bin 800 can collect the lighter waste products blown out by the fan 5, which is convenient for weight. Collection and recycling of lighter waste.

[0065] In some implementations of this embodiment, the lightweight collection bin 800 is detachably connected to the support frame 1 .

[0066] In the above embodiments, the lightweight collection bin 800 is detachably connected to the supporting frame 1 to facilitate the recycling and transfer of light-weight waste products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com