Kitchen waste crushing system and method

A technology of food waste and crushing system, which is applied in the field of waste crushing system and food waste crushing system, which can solve the problems of difficult processing, perishable deterioration, and odor, and achieve the effect of facilitating later transportation and solving greasy and difficult to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

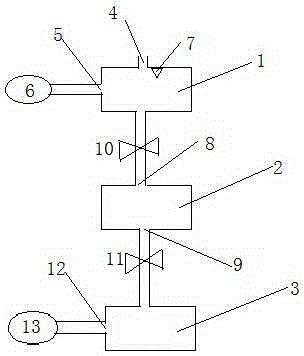

[0034] The food waste crushing system of the present invention includes a treatment area 1, a dehydration area 2 and a winnowing classification area 3 connected in sequence from top to bottom. The top and side of the treatment area 1 are respectively provided with a feed inlet I4 and an air inlet I5, and the air inlet I5 is It communicates with the blower device I6 (Roots blower) outside the treatment area 1. Several acupuncture devices are arranged staggeredly on the inner wall of the treatment area 1, and an activated sludge spraying device 7 is installed near the feed inlet I4. The acupuncture device is a nail plate covered with stainless steel needles on one side, and the other side is connected to the driving device outside the treatment area through a telescopic rod. The length of the stainless steel needle is 2-3cm, and the diameter of the needle body is not more than 0.5mm. The activated sludge spraying device 7 communicates with the activated sludge storage tank above...

Embodiment 2

[0046] The kitchen waste crushing system is the same as that in Embodiment 1, and the specific steps of its waste crushing method are as follows:

[0047] (2) Acupuncture: close the feed inlet I4, drive the acupuncture device forward or backward through the driving device, stop working after repeating 5 times, and make the acupuncture device return to the inner wall of the treatment area 1;

[0048](3) Blowing: Turn on the blowing device I6. After the blowing is over, repeat step (2), and then repeat the blowing and acupuncture operations several times. The flow rate of the air inlet I is 20m / s, and the blowing time is 6 minutes. ;

[0049] (4) Open the valve I, turn on the activated sludge spraying device 7, spray the activated sludge, the weight ratio of the food waste feed to the activated sludge is 1:0.3, close the valve I, and treat the activated sludge for 6 hours;

[0050] (5) Open the valve II10, the material processed in step (4) enters the dehydration zone 2, close ...

Embodiment 3

[0053] The kitchen waste crushing system is the same as that in Embodiment 1, and the specific steps of its waste crushing method are as follows:

[0054] (2) Acupuncture: close the feed inlet I4, drive the acupuncture device forward or backward through the driving device, stop working after repeating 4 times, and make the acupuncture device return to the inner wall of the treatment area 1;

[0055] (3) Blowing: Turn on the blowing device I6. After the blowing is over, repeat step (2), and then repeat the blowing and acupuncture operations several times. The flow rate of the air inlet I is 18m / s, and the blowing time is 5.5 minutes. .

[0056] (4) Open the valve I, open the activated sludge spraying device 7, spray the activated sludge, the weight ratio of the food waste feed to the activated sludge is 1:0.25, close the valve I, and treat the activated sludge for 5 hours;

[0057] (5) Open the valve II10, the material processed in step (4) enters the dehydration zone 2, close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com