High-efficiency integral PCD milling cutter

An overall milling cutter technology, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve problems such as difficult to improve production efficiency, general cutting efficiency, and difficult to improve cutting quality, so as to improve production efficiency, reduce assembly costs, and improve The effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

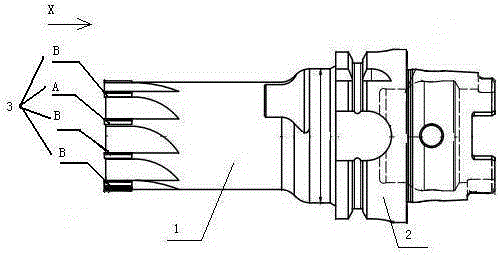

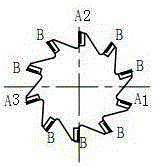

[0012] A high-efficiency PCD integral milling cutter, which includes a cutter head 1 and a handle 2, the cutter head 1 and the handle 2 are in an integrated structure, the top of the cutter head 1 is provided with a plurality of blades 3, and the blades 3. The number is 10, which are evenly distributed in the circumferential direction around the top of the cutter head 1; the blade 3 includes a blade A and a blade B, the number of the blade A is three, and the number of the blade B is 7. The blade A includes a first blade A1, a second blade A2, and a third blade A3. There are two blades B between the first blade A1 and the second blade A2, and between the second blade A2 and the third blade A3. Two cutting edges B are separated, and three cutting edges B are separated between the third cutting edge A3 and the first cutting edge A1. The tooth at the end A of the blade is 0.015-0.018cm higher than the tooth at the end B of the blade. The size and shape of the first blade A1 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com