Laser speckle eliminating device with dodging function

A laser speckle and optical function technology, applied in optics, optical components, instruments, etc., can solve the problem of unimproved beam non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments.

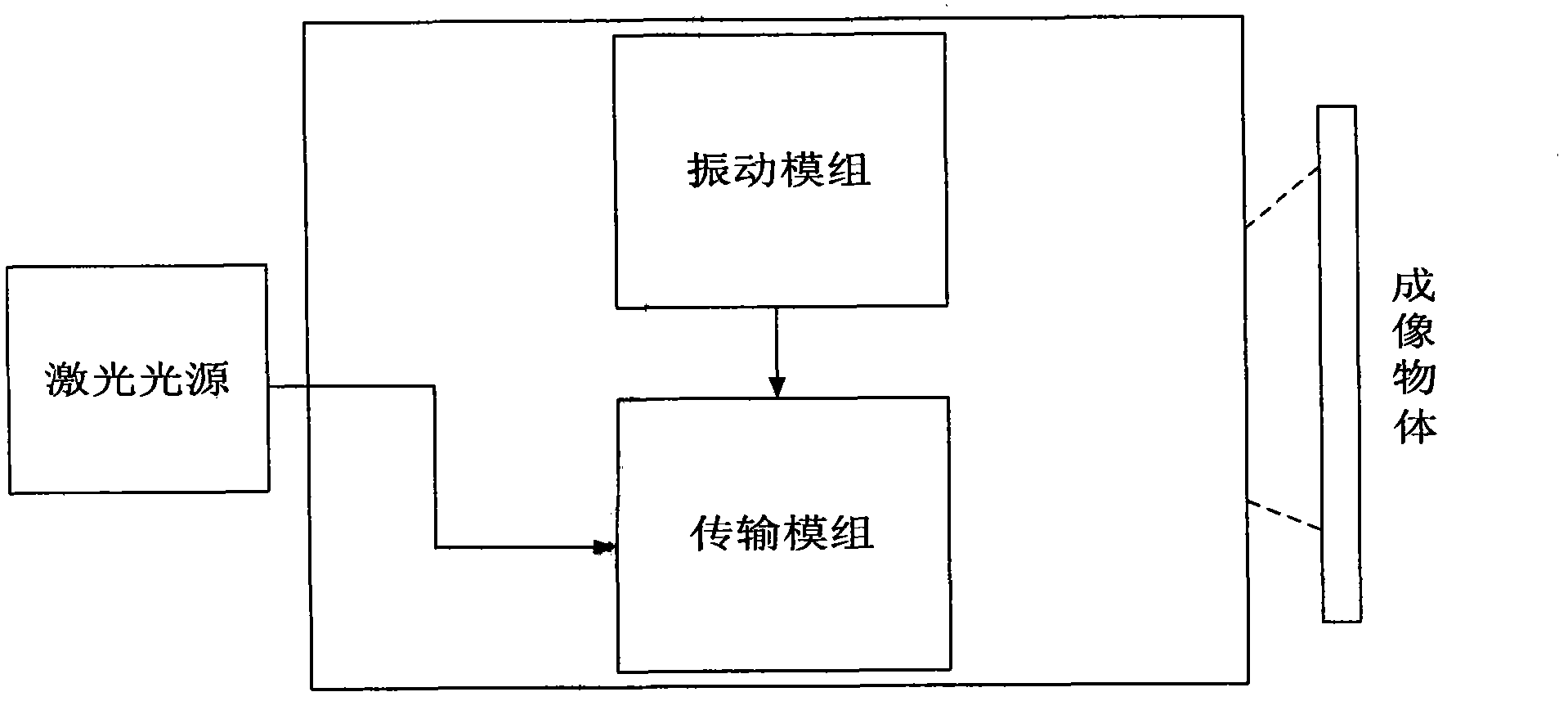

[0019] figure 2 It is a structural schematic diagram of the laser speckle elimination device with uniform light function of the present invention, including a laser light source, a transmission medium, a vibration module, and the vibration module is fixedly connected to the transmission medium.

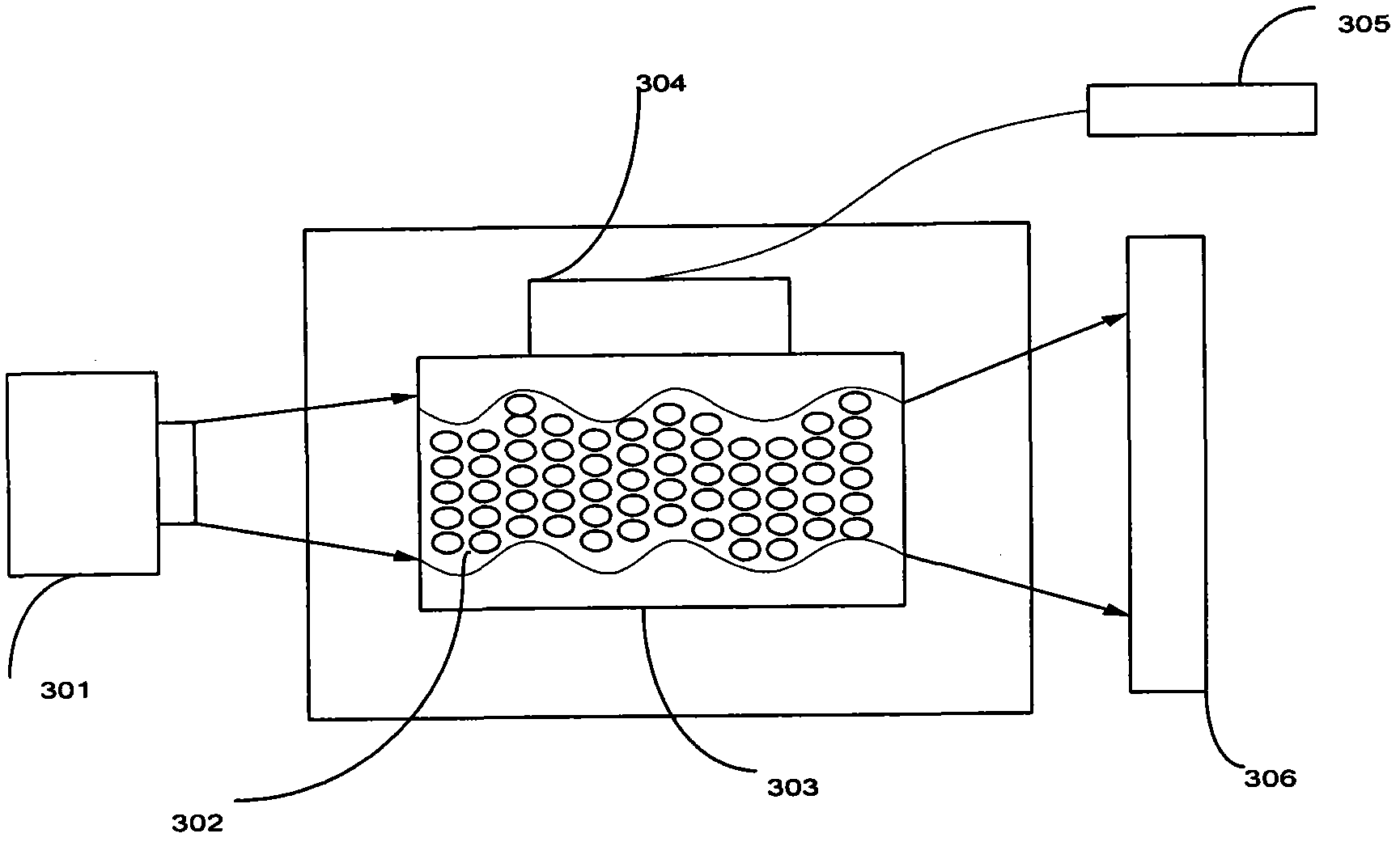

[0020] image 3 It shows the internal structure diagram and optical path schematic diagram of the present invention, wherein the laser beam 301 emitted by the laser light source is transmitted through the transmission medium 303 with the scatterer 302 inside, and the scatterer 302 is made of a material different from the transmission medium 303 and is distributed with a uniform density In the transmission medium, under normal circumstances, the transmission medium 303 can be made of polymethyl methacrylate, while the scatterer 302 mostly uses 4 μm SiO with a mass fraction of 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com