Ceramic wall and floor tile material distributing device capable of forming lines and textures of natural stone

A technology for distributing devices and wall and floor tiles, which is applied to supply devices, ceramic molding machines, auxiliary molding equipment, etc., can solve problems such as large gaps and inability to be truly and naturally reflected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

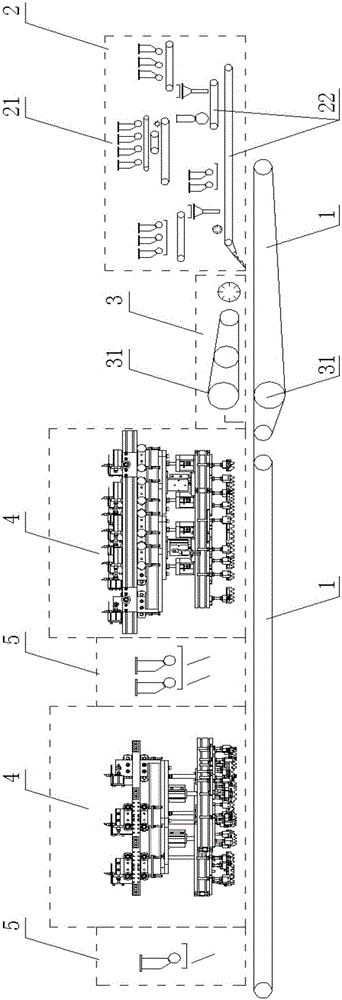

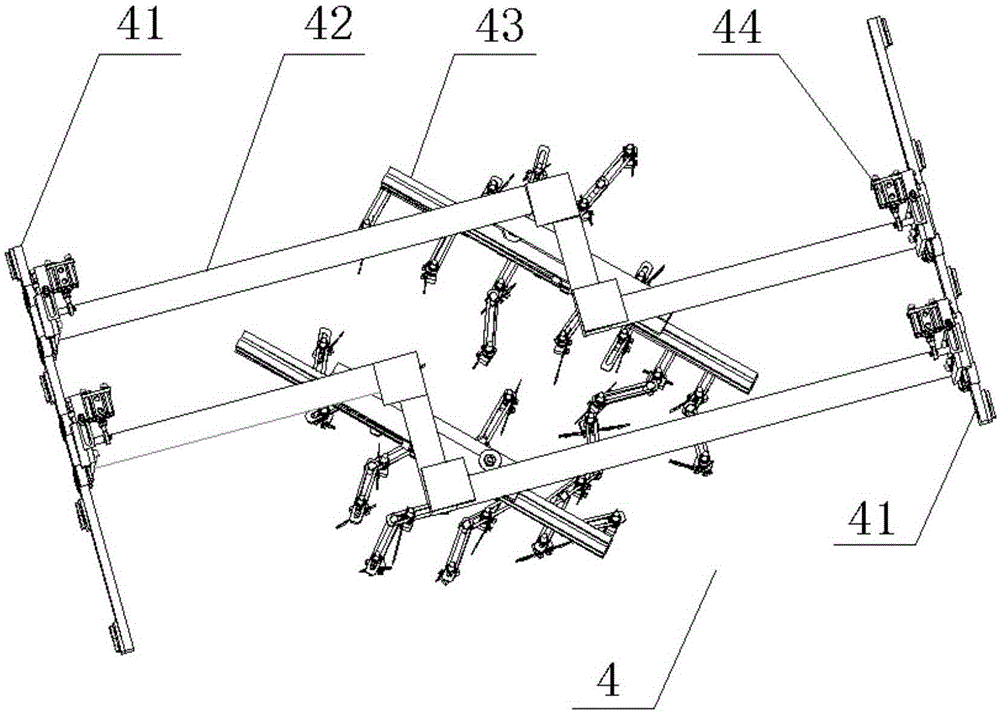

[0011] The invention as figure 1 , figure 2 , image 3 , Figure 4 Shown: a ceramic wall and floor tile distributing device capable of forming natural stone line textures, including a main drive conveyor belt 1 arranged on the frame, and its characteristic is that a fabric distributing device 2, a fabric fabric distributing device 2, and a fabric Pre-pressing device 3, line cutter device 4, and line powder material distributing device 5, described fabric distributing device 2 comprises several fabric buckets 21 with rollers and fabric conveyer belt 22, is provided with a group of behind the fabric conveyer belt output end Fabric pre-pressing device 3, the pre-pressing device is a group of belts 31 with opposing pressure rollers, after the fabric pre-pressing device 3, two sets of line cutter devices 4 and two sets of line powder distributing devices 5 are arranged.

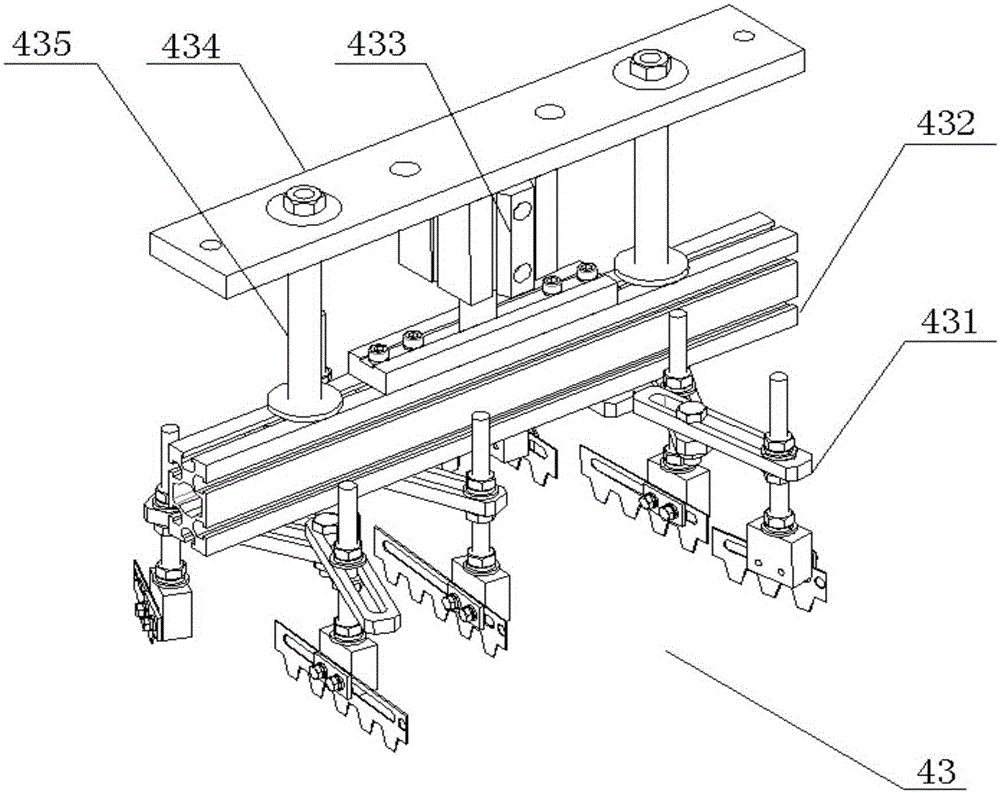

[0012] The line cutter device 4 includes: one group of guide rails 41, several groups of beam frames 42, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com