Apparatus and method of producing sounding balloon by impregnation method

A technology of sounding air balloons and dipping method, which is applied to hollow objects, other household appliances, household appliances, etc., which can solve the problems of complex production process, difficult production, and high cost of hard models, and reduce the difficulty of demoulding and low cost , easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

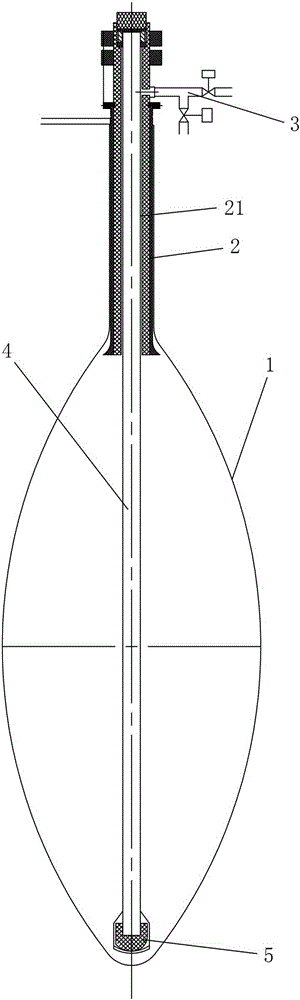

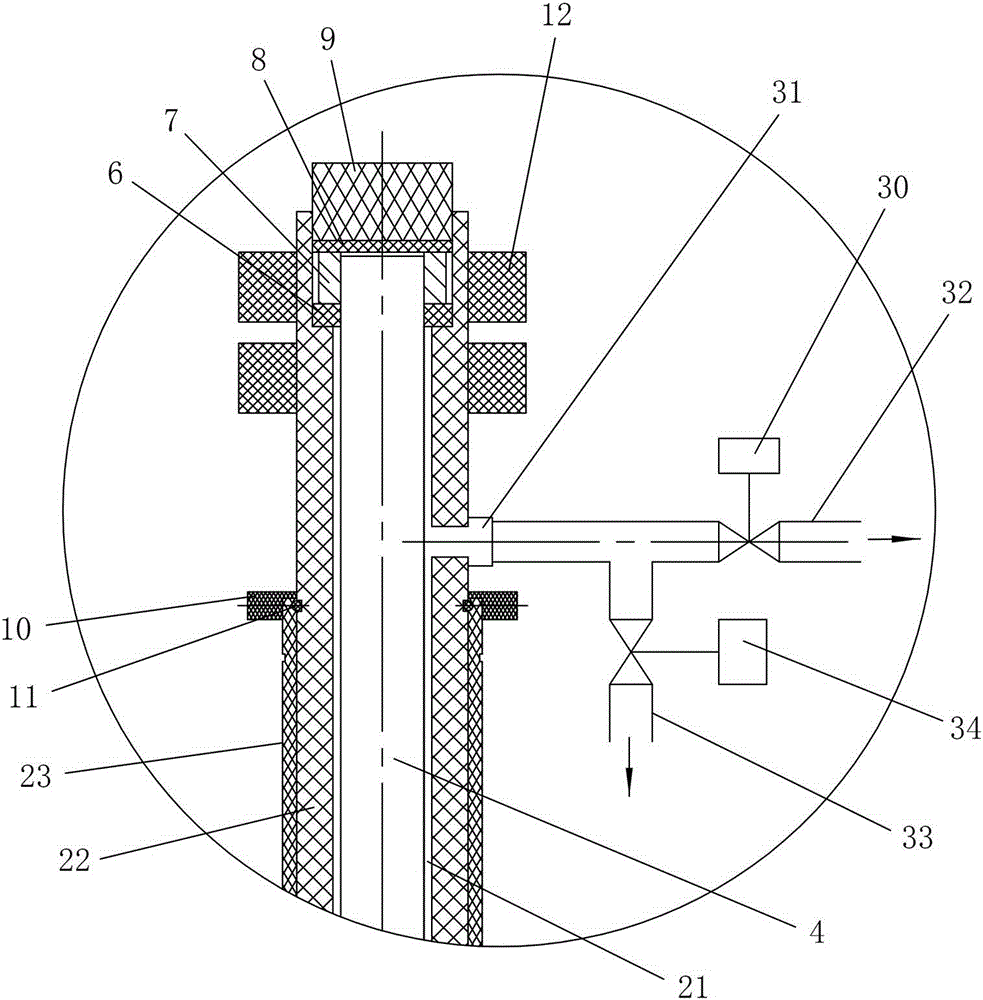

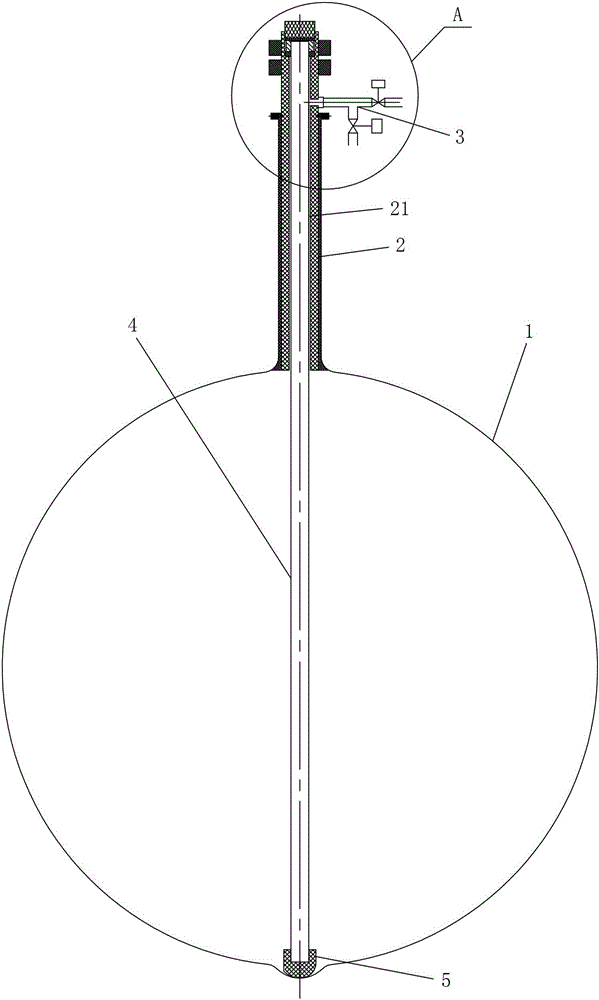

[0029] Such as figure 1 with figure 2 As shown, the device for producing sounding balloons by the dipping method of the present invention includes an inflatable balloon 1 and a handle 2 connected to the inflatable balloon 1. A gas channel 21 is arranged in the handle 2, and one end of the gas channel 21 It communicates with the inner cavity of the inflatable balloon 1 , and the other end is connected with an inflation and deflation component 3 for inflating and deflating the inflatable balloon 1 . The device for producing sounding air balloons by dipping method of the present invention adopts the combination of ball handle 2 and inflatable balloon 1 to form a model for dipping and producing sounding air balloons, and the inflatable air balloon 1 can be inflated or inflated by inflation and deflation components 3 , it is convenient ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com