Automatic arranging and conveying mechanism

A transmission mechanism and automatic arrangement technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of easy leakage, low work efficiency, and difficult control of workpiece clamping force, so as to increase processing speed and high processing efficiency , the effect of reducing the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

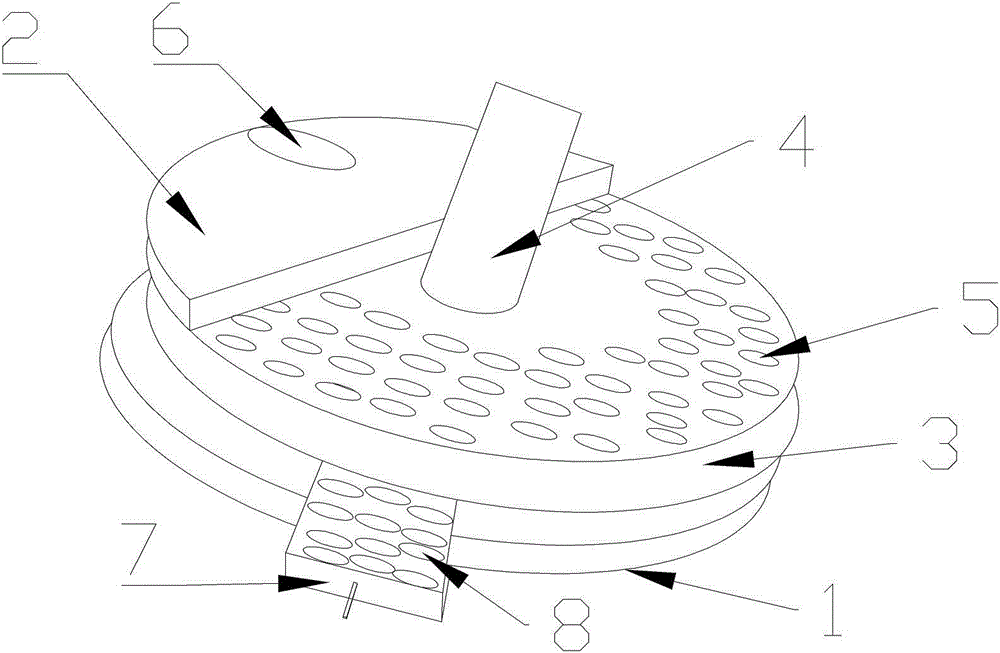

[0015] The reference signs in the accompanying drawings of the specification include: chassis 1 , top plate 2 , turntable 3 , rotating shaft 4 , through hole 5 , inlet 6 , workpiece disc 7 , and workpiece hole 8 .

[0016] The embodiment is basically as attached figure 1 As shown: It includes chassis 1, top plate 2, and turntable 3 that are bonded together. The turntable 3 is located between the chassis 1 and the top plate 2. The middle of the turntable 3 is connected to the rotating shaft 4. The top of the rotating shaft 4 passes through the top plate 2 and extends Outside the top plate 2, the rotating shaft 4 is driven by a motor. The through holes 5 are evenly distributed on the turntable 3, and the size of the through holes 5 matches the size of the workpiece. One through hole 5 can only accommodate one workpiece; Have inlet 6, and the diameter length of inlet 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com