Novel production process of sodium hypochlorite

A sodium hypochlorite and production process technology, applied in the direction of hypochlorous acid and hypochlorite, can solve problems such as unstable quality, high operating intensity, and inability to achieve real-time monitoring, so as to improve quality stability, accuracy, The effect of reducing the work intensity of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

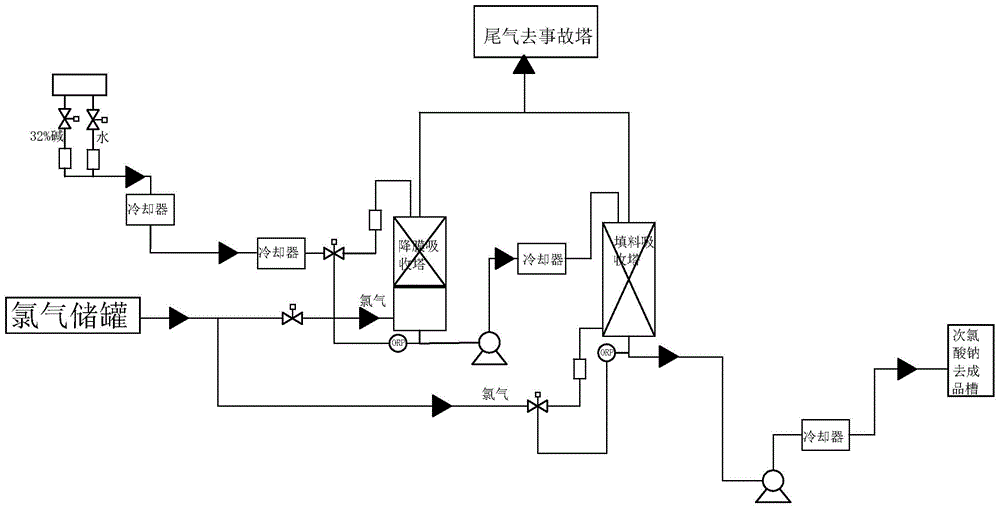

[0020] A kind of production technique of novel sodium hypochlorite, comprises the following steps,

[0021] a. Dilute 32% sodium hydroxide with water to 20% sodium hydroxide,

[0022] b. Put the diluted sodium hydroxide solution into the cooler to cool down, pass the condensed product into the falling film absorption tower, and pass chlorine gas into the falling film absorption tower for reaction, the reaction temperature is 10-30°C, and the reaction product available chlorine is 7% ~ 8.5% sodium hypochlorite solution,

[0023] c. Cool the sodium hypochlorite solution through a cooler, pass the condensed product into the packed absorption tower, add chlorine gas into the packed absorption tower, and the reaction temperature is 10-30°C to obtain a sodium hypochlorite solution with 9%-10.5% available chlorine in the reaction product,

[0024] d. The sodium hypochlorite solution after the reaction enters the cooler for cooling, and passes into the finished product storage ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap