Compact clay brick for blast furnace

A dense clay and blast furnace technology, applied in the field of refractory materials, can solve problems such as affecting the production of blast furnaces and being unsuitable for use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

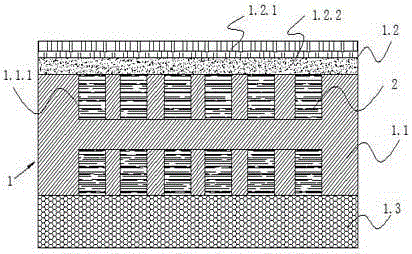

[0013] Embodiment 1: dense clay bricks for blast furnaces, including a base body 1, a base layer 1.1 including the center and a dense layer 1.2 arranged on the upper surface of the base layer 1.1, a microporous insulation layer 1.3 is provided on the lower surface of the base layer 1.1, and the thickness of the microporous insulation layer 1.3 is The thickness of the base layer 1.1 is 1 / 3, and the thickness of the dense layer 1.2 is 1 / 5 of the base layer 1.1. The surface of the base layer 1.1 is evenly distributed with dead holes 1.1.1 with a diameter of 10mm~15mm, and cement slurry 2 is poured in the dead holes 1.1.1. The base layer 1.1 is formed by high-temperature sintering of yellow sand and water. The dense layer 1.2 is press-bonded with the base layer 1.1 at high temperature. The microporous insulation layer 1.3 is formed by mixing and sintering grass ash and clay.

[0014] The micropores of the microporous insulation layer 1.3 are irregular holes. The dense layer 1.2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com